The most significant recent innovations in dental sintering furnace technology are the integration of advanced heating elements and the seamless incorporation into digital workflows. Modern furnaces now commonly use Molybdenum disilicide (MoSi2) heating elements for greater longevity and heating precision, while direct integration with 3D printing and scanning systems dramatically reduces overall production time.

The evolution of the sintering furnace is no longer just about applying heat. It's about transforming the device into an intelligent, integrated hub that boosts a dental lab's overall efficiency, material versatility, and final product quality.

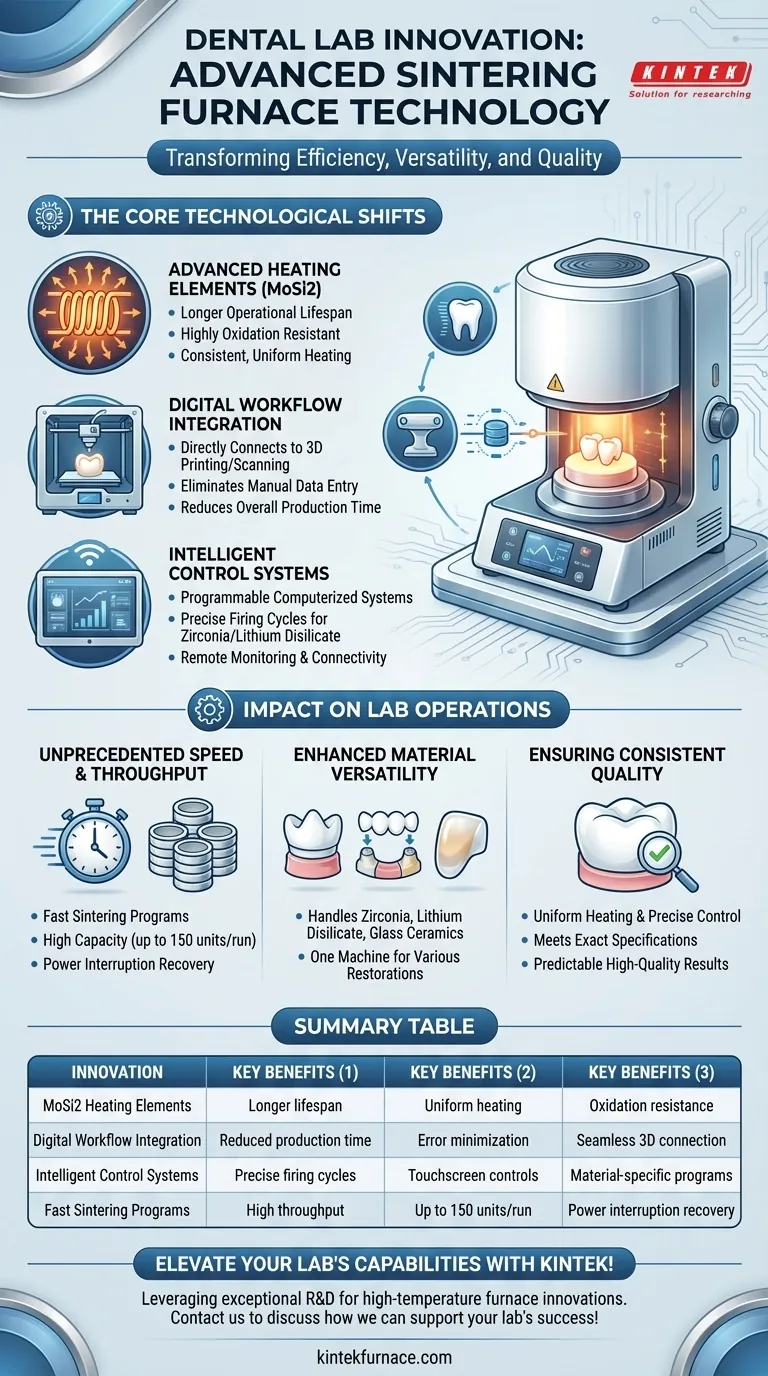

The Core Technological Shifts

Modern sintering furnaces have moved beyond simple heating chambers to become sophisticated, electronically controlled devices. This evolution is driven by key advancements in materials science and software integration.

Advanced Heating Elements (MoSi2)

The adoption of molybdenum disilicide (MoSi2) as the primary material for heating elements is a critical upgrade. Unlike traditional elements, MoSi2 is highly resistant to oxidation, even at the high temperatures required for sintering zirconia.

This resistance translates directly to a longer operational lifespan and more consistent, uniform heating cycles. This reliability is fundamental to achieving predictable and high-quality restorations every time.

Digital Workflow Integration

The most impactful innovation for lab efficiency is the furnace's integration into the digital dental workflow. Technicians can now 3D print a restoration, scan it, and send the data directly to the furnace.

This seamless connection eliminates manual data entry and reduces the potential for error. The result is a significant reduction in both production time and the manual effort required for each case.

Intelligent Control Systems

Today's furnaces are equipped with programmable, computerized systems. Features like touchscreen controls, pre-set programs for specific materials, and even internet connectivity are becoming standard.

These intelligent controls allow for precise management of the firing cycle, ensuring that materials like zirconia and lithium disilicate are processed under ideal conditions to maintain their structural integrity and aesthetic properties.

How These Innovations Impact Lab Operations

These technological shifts have a direct and measurable impact on a dental lab's daily productivity, quality control, and overall capacity.

Unprecedented Speed and Throughput

Modern furnaces are designed for high-volume environments. Features like fast sintering programs and the ability to stack multiple crucibles—allowing some models to process up to 150 units in a single run—drastically increase a lab's output.

Furthermore, functions like power interruption recovery ensure that long cycles can complete successfully even if a brief power outage occurs, preventing costly losses of time and material.

Enhanced Material Versatility

Advanced temperature control and programmable cycles allow a single furnace to expertly handle a wide range of dental ceramics. This includes popular materials like zirconia, lithium disilicate, and other pressable glass ceramics.

This versatility means labs can use one machine to produce crowns, bridges, veneers, and implants, maximizing the return on their investment.

Ensuring Consistent Quality

The combination of uniform heating from MoSi2 elements and the precision of computerized controls leads to a higher standard of quality. This technology ensures every restoration meets the exact specifications required, enhancing the lab's reputation and efficiency.

Understanding the Trade-offs and Practical Considerations

While advanced technology offers significant benefits, it is crucial to approach the investment with a clear understanding of the practical realities.

The Importance of Support and Reliability

A furnace's value extends beyond its technical specifications. Evaluating the manufacturer's reputation, warranty coverage, and after-sales support is critical. A reliable supply chain for parts and responsive technical assistance ensures minimal downtime.

The Human Factor: Safety and Maintenance

Even with automation, operator safety remains paramount. Technicians must use appropriate protective gear, such as heat-resistant gloves and goggles, and strictly follow manufacturer instructions.

Regular cleaning and maintenance are also non-negotiable. Preventing dust accumulation and ensuring the furnace is in optimal condition are key to both safety and maintaining consistent product quality.

Making the Right Choice for Your Lab

Selecting the right furnace depends entirely on your lab's specific goals and workflow priorities.

- If your primary focus is maximum throughput: Prioritize furnaces with high-capacity stacking trays, validated fast-sintering programs, and power-interruption recovery.

- If your primary focus is digital workflow integration: Look for models with proven compatibility with your existing 3D printing and scanning systems and user-friendly software.

- If your primary focus is long-term reliability and low maintenance: Choose a furnace featuring MoSi2 heating elements and backed by a strong manufacturer warranty and responsive customer support.

Investing in the right furnace technology empowers your lab to deliver higher quality restorations more efficiently than ever before.

Summary Table:

| Innovation | Key Benefits |

|---|---|

| MoSi2 Heating Elements | Longer lifespan, uniform heating, oxidation resistance |

| Digital Workflow Integration | Reduced production time, error minimization, seamless 3D printing/scanner connection |

| Intelligent Control Systems | Precise firing cycles, touchscreen controls, material-specific programs |

| Fast Sintering Programs | High throughput, up to 150 units per run, power interruption recovery |

Elevate your dental lab's capabilities with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace innovations tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is enhanced by strong deep customization to precisely meet unique experimental requirements. Experience improved efficiency, material versatility, and consistent quality—contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations