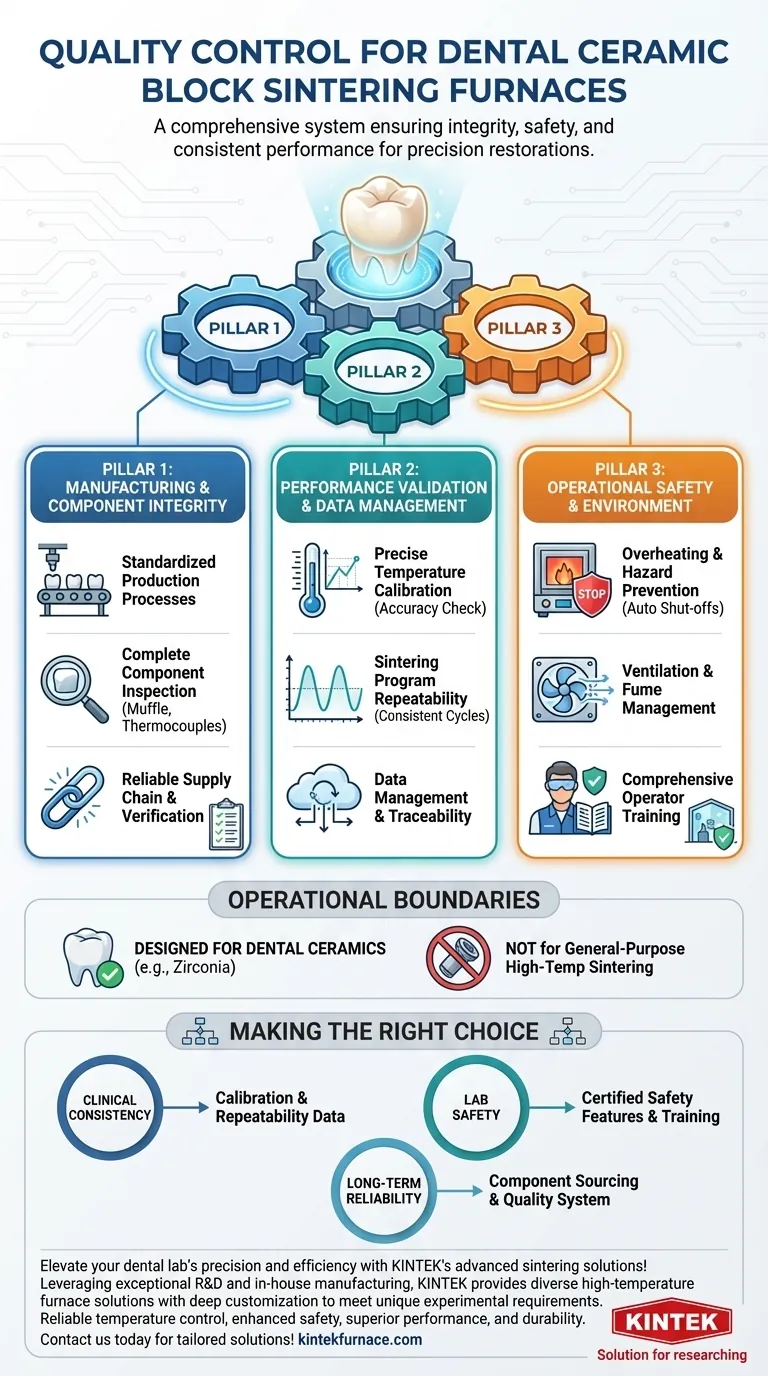

At its core, quality control for dental ceramic block sintering furnaces is a comprehensive system that ensures manufacturing integrity, operational safety, and consistent performance. This involves everything from rigorous component inspection during production and precise temperature calibration to built-in safety mechanisms that prevent overheating and mandated operator training.

The ultimate goal of furnace quality control is not just to build a functional machine, but to guarantee its ability to reliably and repeatedly execute precise heating cycles. This precision is the deciding factor in the final strength, fit, and aesthetic quality of a ceramic dental restoration.

The Pillars of Furnace Quality Control

True quality assurance for these critical devices rests on three distinct but interconnected pillars: manufacturing standards, performance validation, and operational safety.

Pillar 1: Manufacturing and Component Integrity

The quality of the final product begins with the quality of its individual parts and the process used to assemble them.

Standardized Production Processes Manufacturers implement standardized production lines to ensure that every furnace is built to the exact same specifications. This consistency is the foundation of reliable performance from one unit to the next.

Supply Chain Verification A reliable supply chain is a critical, often overlooked, quality measure. Manufacturers must vet their suppliers to ensure that every component, from the heating elements to the control board electronics, meets strict performance and longevity standards.

Complete Component Inspection Before and during assembly, components undergo complete inspection. This includes testing the muffle (heating chamber), thermocouples (temperature sensors), and electronic controllers to catch any potential defects before the unit is finalized.

Pillar 2: Performance Validation and Data Management

A well-built furnace must also prove it can perform its core function—sintering—with absolute precision.

Precise Temperature Calibration This is arguably the most critical quality check. Each furnace is calibrated to ensure temperature accuracy. A deviation of even a few degrees can compromise the ceramic's structure, affecting its strength and appearance. This calibration ensures the furnace reaches and holds the exact temperatures required by the ceramic material's specifications.

Sintering Program Repeatability Technicians test the furnace by running multiple sintering cycles to verify program repeatability. The furnace must execute the same complex heating and cooling sequence perfectly every time to produce consistent results for the dental lab.

Data Management and Traceability Modern quality control involves massive data management. During testing, performance data from each furnace is logged and tracked. This creates a traceable record, allowing manufacturers to identify trends and continuously improve their production process.

Pillar 3: Operational Safety and Environment

A quality furnace is also a safe one, both for the operator and the lab environment.

Overheating and Hazard Prevention Furnaces are equipped with critical safety features, such as automatic shut-offs, to prevent overheating. These systems protect the unit from damage and, more importantly, mitigate the risk of fire in the dental lab.

Ventilation and Fume Management The sintering process can release fumes from the burnout of organic materials in the ceramic. Quality guidelines mandate that these furnaces be used in well-ventilated areas, and their design often facilitates safe fume extraction.

The Role of Operator Training The final layer of quality control is a properly trained user. Manufacturers and safety protocols stress the importance of comprehensive operator training to ensure the equipment is used correctly, safely, and effectively.

Understanding the Operational Boundaries

Understanding a furnace's limitations is as important as knowing its features. This is a key part of using the equipment correctly.

Designed for Dental Ceramics

These furnaces are highly specialized. They are engineered to execute the precise temperature curves required for materials like zirconia. They are not suitable for general-purpose, high-temperature sintering of other materials or metals, which require different atmospheres and much higher heat.

Temperature and Application Limits

The quality control process ensures the furnace operates flawlessly within its specified temperature range. Attempting to push the unit beyond these limits can lead to inconsistent results and damage the heating elements. Using it for the intended ceramic materials is essential for predictable outcomes.

Making the Right Choice for Your Goal

When evaluating a sintering furnace, match its quality control strengths to your primary needs.

- If your primary focus is clinical consistency: Look for manufacturers who provide documentation on their temperature calibration methods and guarantees of program repeatability.

- If your primary focus is lab safety: Prioritize furnaces with certified safety features (like overheating protection) and ensure your team receives documented operational training.

- If your primary focus is long-term reliability: Inquire about the manufacturer's component sourcing, data-driven production testing, and overall quality management system.

Ultimately, understanding these quality measures empowers you to select and operate equipment that delivers predictable, high-quality restorations for your patients.

Summary Table:

| Quality Control Pillar | Key Measures |

|---|---|

| Manufacturing and Component Integrity | Standardized production, supply chain verification, component inspection |

| Performance Validation and Data Management | Temperature calibration, program repeatability, data logging |

| Operational Safety and Environment | Overheating prevention, ventilation, operator training |

Elevate your dental lab's precision and efficiency with KINTEK's advanced sintering solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need reliable temperature control for consistent ceramic restorations or enhanced safety features for a secure lab environment, our furnaces are designed to deliver superior performance and durability.

Contact us today to discuss how our tailored solutions can meet your specific needs and drive success in your dental applications!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations