In short, a retort furnace is used for advanced material treatments that require a highly controlled atmosphere, such as carburizing, nitriding, sintering, and annealing. Its defining feature is a sealed chamber, the retort, which isolates the material from external contaminants and the furnace's heating elements. This design allows for precise regulation of both temperature and the gaseous environment.

A retort furnace's value is not just the heat it provides, but the isolated, perfectly controlled atmosphere it creates. This control is the key that unlocks a range of high-purity and surface modification processes impossible in an open-air furnace.

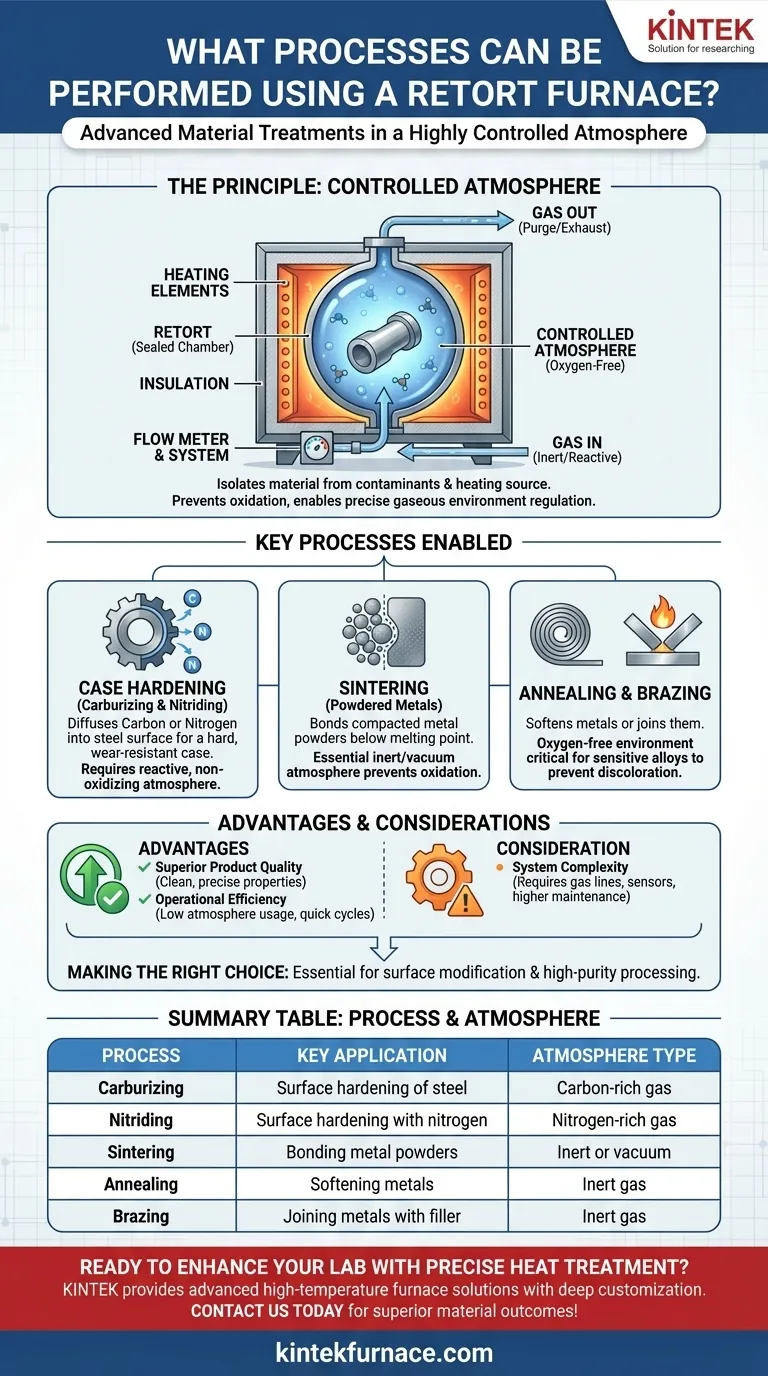

The Principle of the Retort Furnace: Controlled Atmosphere

The primary function that differentiates a retort furnace is its ability to meticulously manage the atmosphere surrounding the part being treated. This capability is fundamental to its use in specialized applications.

What is a "Retort"?

A retort is a sealed vessel, typically made of metal or ceramic, that sits inside the furnace. The material to be heat-treated is placed inside this vessel.

This retort physically separates the workspace from the furnace's insulation and heating source. This separation is the key to creating a pure, controlled environment.

The Critical Role of Atmosphere Control

Many advanced heat treatments fail in the presence of oxygen or other reactive gases found in air. These gases can cause unwanted oxidation, scaling, and contamination, degrading the material's properties.

A retort furnace allows operators to purge the air and introduce specific gases. These can be inert gases like Argon to prevent reactions, or reactive gases like nitrogen or carbon-rich gases to intentionally modify the material's surface.

How It Achieves Precision

These furnaces are equipped with sophisticated atmosphere control systems to introduce, regulate, and monitor the specialized gases within the retort.

Combined with a precise temperature control system, this allows for repeatable, high-quality results by ensuring every part of the process—from heating to soaking and cooling—occurs under the exact intended conditions.

Key Processes Enabled by Retort Furnaces

The unique atmospheric control of a retort furnace makes it essential for several specific industrial processes where material purity and surface integrity are paramount.

Case Hardening: Carburizing and Nitriding

Carburizing and nitriding are processes that diffuse carbon or nitrogen into the surface of a steel part to create a hard, wear-resistant outer layer (the "case").

A retort furnace is ideal because it can contain the carbon-rich or nitrogen-rich atmospheres required for this diffusion to occur at high temperatures without oxidizing the part itself.

Sintering of Powdered Metals

Sintering is the process of heating compacted metal powders to just below their melting point, causing the particles to bond and form a solid piece.

During this process, the material is extremely vulnerable to oxidation. A retort furnace provides the necessary inert or vacuum atmosphere to prevent oxidation and ensure strong, pure metallic bonds.

Annealing and Brazing

Annealing softens a metal to make it more workable, while brazing joins two metals using a filler material.

For many sensitive alloys, performing these processes in an oxygen-free environment is critical to prevent surface discoloration and maintain material integrity. The sealed retort provides this necessary protection.

Understanding the Advantages and Trade-offs

While powerful, a retort furnace represents a specific engineering choice with clear benefits and considerations compared to simpler furnace designs.

Advantage: Superior Product Quality

The primary advantage is a higher-quality end product. By preventing contamination and oxidation, parts emerge from the furnace clean and with the precise metallurgical properties intended.

Advantage: Operational Efficiency

The sealed retort has low atmosphere usage because the gas volume is small and contained, reducing operational costs. Modern designs also feature efficient heat transfer, leading to quicker heating cycles and reduced energy consumption.

Consideration: System Complexity

The components required for atmosphere control—gas lines, flow meters, sensors, and safety purges—make a retort furnace inherently more complex than a standard air furnace. This can translate to higher initial investment and maintenance requirements.

Making the Right Choice for Your Application

Selecting a retort furnace depends entirely on whether the process demands atmospheric control.

- If your primary focus is surface modification (carburizing, nitriding): A retort furnace is essential for containing the required reactive gas atmospheres.

- If your primary focus is high-purity processing (sintering, brazing, annealing sensitive metals): The sealed, inert atmosphere of a retort furnace is non-negotiable to prevent oxidation.

- If your primary focus is general heat treatment (like tempering low-alloy steel): A simpler and more cost-effective conventional furnace is likely sufficient if a controlled atmosphere is not a critical requirement.

Ultimately, choosing a retort furnace is a decision to prioritize precise atmospheric control to achieve superior material outcomes.

Summary Table:

| Process | Key Application | Atmosphere Type |

|---|---|---|

| Carburizing | Surface hardening of steel | Carbon-rich gas |

| Nitriding | Surface hardening with nitrogen | Nitrogen-rich gas |

| Sintering | Bonding metal powders | Inert or vacuum |

| Annealing | Softening metals | Inert gas |

| Brazing | Joining metals with filler | Inert gas |

Ready to enhance your lab's capabilities with precise heat treatment? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our retort furnaces can deliver superior material outcomes for your specific applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process