The process is known as firing. This is a critical manufacturing step where heat is precisely applied to dental ceramic materials inside a specialized porcelain furnace. The goal of firing is to transform the weak, porous ceramic compact into a dense, strong, and aesthetically pleasing final dental restoration.

Firing is not simply heating. It is a highly controlled thermal process that dictates the final strength, color, fit, and longevity of a ceramic crown, veneer, or bridge. Mastering the variables of the firing cycle is what separates a successful restoration from a failure.

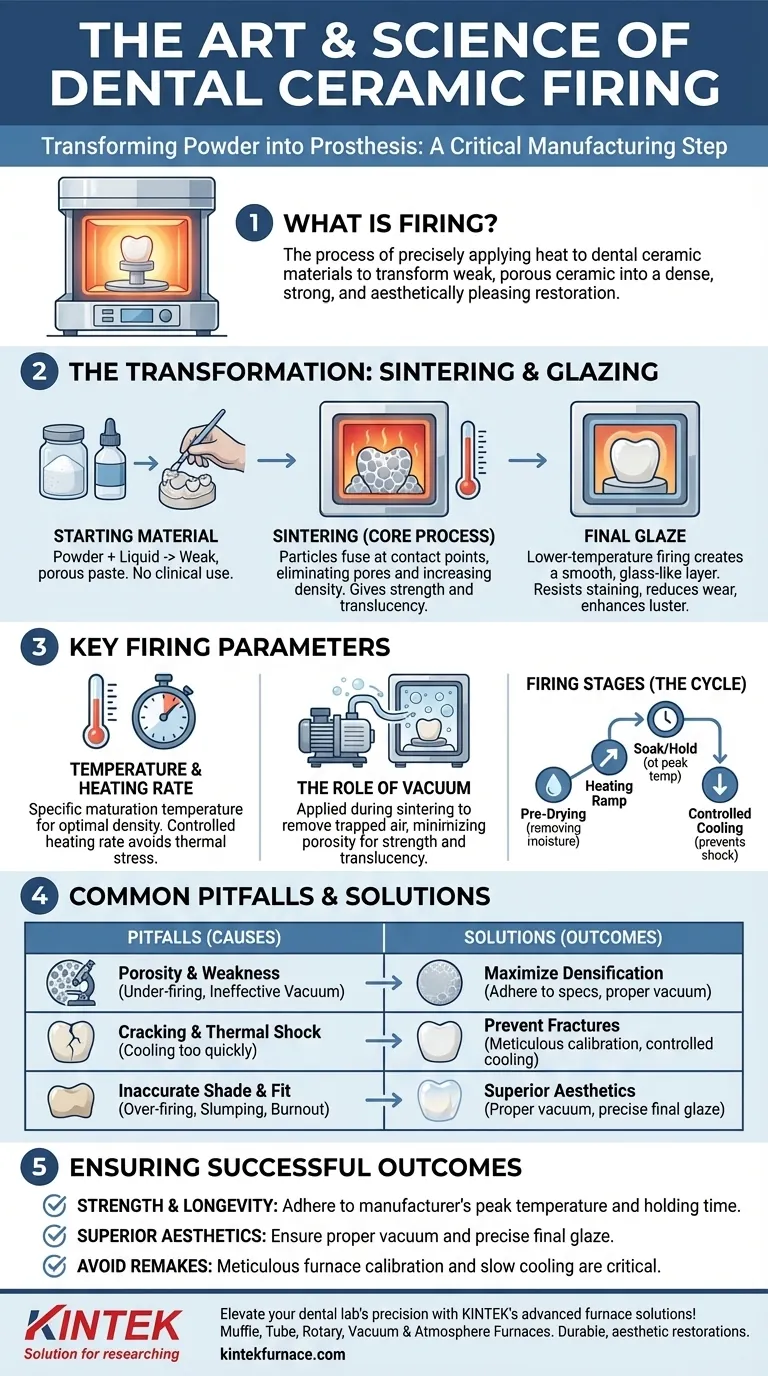

The Goal of Firing: From Powder to Prosthesis

The fundamental purpose of firing is to convert a shaped, fragile ceramic material into a durable and functional prosthesis. This transformation happens through several key physical and chemical changes.

The Starting Material

Most dental ceramics begin as a fine powder. A dental technician mixes this powder with a liquid to form a paste, which is then carefully sculpted onto a model of the patient's tooth. At this stage, the material is weak and has no clinical use.

The Transformation: Sintering

The core process that occurs during firing is sintering. As the temperature rises in the furnace, the individual ceramic particles begin to fuse at their contact points. This process eliminates the gaps and pores between particles, causing the material to shrink and become significantly more dense.

Achieving Strength and Translucency

This densification is what gives the ceramic its final strength and hardness. It also dramatically improves the material's optical properties, transforming it from an opaque powder into a translucent structure that can mimic the appearance of natural tooth enamel.

The Final Glaze

Most restorations undergo a final, lower-temperature firing cycle called glazing. This creates a smooth, glass-like layer on the surface. A proper glaze makes the restoration resistant to staining, reduces wear on opposing teeth, and enhances its final aesthetic luster.

Inside the Porcelain Furnace: Key Firing Parameters

A successful outcome depends entirely on the precise control of the firing environment. Technicians program the porcelain furnace with a specific firing cycle based on the ceramic manufacturer's instructions.

Temperature and Heating Rate

Each type of ceramic has a specific maturation temperature at which it achieves optimal density. The rate at which this temperature is reached (the heating rate) is also critical. Heating too quickly can create thermal stress and cause cracks.

The Role of Vacuum

During the initial stages of sintering, a vacuum is typically applied inside the furnace. This helps remove air trapped between the ceramic particles before they fuse together. Removing this air is essential for minimizing internal porosity, which is a major cause of weakness and opacity.

Firing Stages: The Cycle

A typical firing cycle isn't a single event. It involves a pre-drying phase to remove moisture, a controlled heating ramp, a "soak" or hold at the peak temperature to ensure uniform sintering, and finally, a controlled cooling phase to prevent thermal shock.

Understanding the Trade-offs and Common Pitfalls

Deviating from the ideal firing protocol can lead to a failed restoration. Understanding these risks is crucial for any dental professional or technician.

Porosity and Weakness

Under-firing (not reaching the correct temperature) or an ineffective vacuum will result in a porous restoration. Porosity acts as a stress concentration point, making the ceramic weak, brittle, and prone to fracture under chewing forces.

Cracking and Thermal Shock

Cooling the restoration too quickly is a common cause of failure. The outer surface cools and contracts faster than the interior, creating immense internal stress that can lead to micro-cracks or catastrophic fractures.

Inaccurate Shade and Fit

Over-firing (exceeding the recommended temperature or time) can cause the ceramic to "slump" and lose its shape, leading to a poor fit. It can also burn out the color pigments within the ceramic, resulting in an incorrect and unappealing shade.

Ensuring a Successful Firing Outcome

The success of a ceramic restoration is baked in during the firing cycle. The right approach depends on prioritizing the most critical outcome for the specific clinical situation.

- If your primary focus is strength and longevity: Adherence to the manufacturer's specified peak temperature and holding time is non-negotiable to achieve maximum densification.

- If your primary focus is superior aesthetics: Proper vacuum application to eliminate internal porosity is key for achieving high translucency, and a precise final glaze cycle is essential for a lifelike surface texture.

- If your primary focus is avoiding remakes and ensuring accuracy: Meticulous furnace calibration and a slow, controlled cooling protocol are the most critical factors for preventing fractures and ensuring the restoration fits perfectly.

Ultimately, mastering the science of ceramic firing is fundamental to consistently producing high-quality, durable, and aesthetic dental restorations.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process Name | Firing |

| Main Goal | Transform ceramic powder into a dense, strong, and aesthetic dental prosthesis |

| Core Mechanism | Sintering (particle fusion) |

| Key Parameters | Temperature, heating rate, vacuum application, cooling rate |

| Common Pitfalls | Porosity (under-firing), cracking (thermal shock), inaccurate shade/fit (over-firing) |

| Success Factors | Adherence to manufacturer specs, controlled cooling, proper glazing |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for dental ceramics, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met, delivering durable, aesthetic restorations with every firing cycle. Contact us today to discuss how our solutions can enhance your workflow and outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations