Beyond metals, the primary beneficiaries of inert atmosphere heat treatment are specific high-performance polymers whose properties are sensitive to oxygen at elevated temperatures. This includes advanced plastics like PTFE (Teflon) and Ultra-High-Molecular-Weight (UHMW) polyethylene, which require an inert environment during processes like sintering to prevent chemical degradation and preserve their unique performance characteristics.

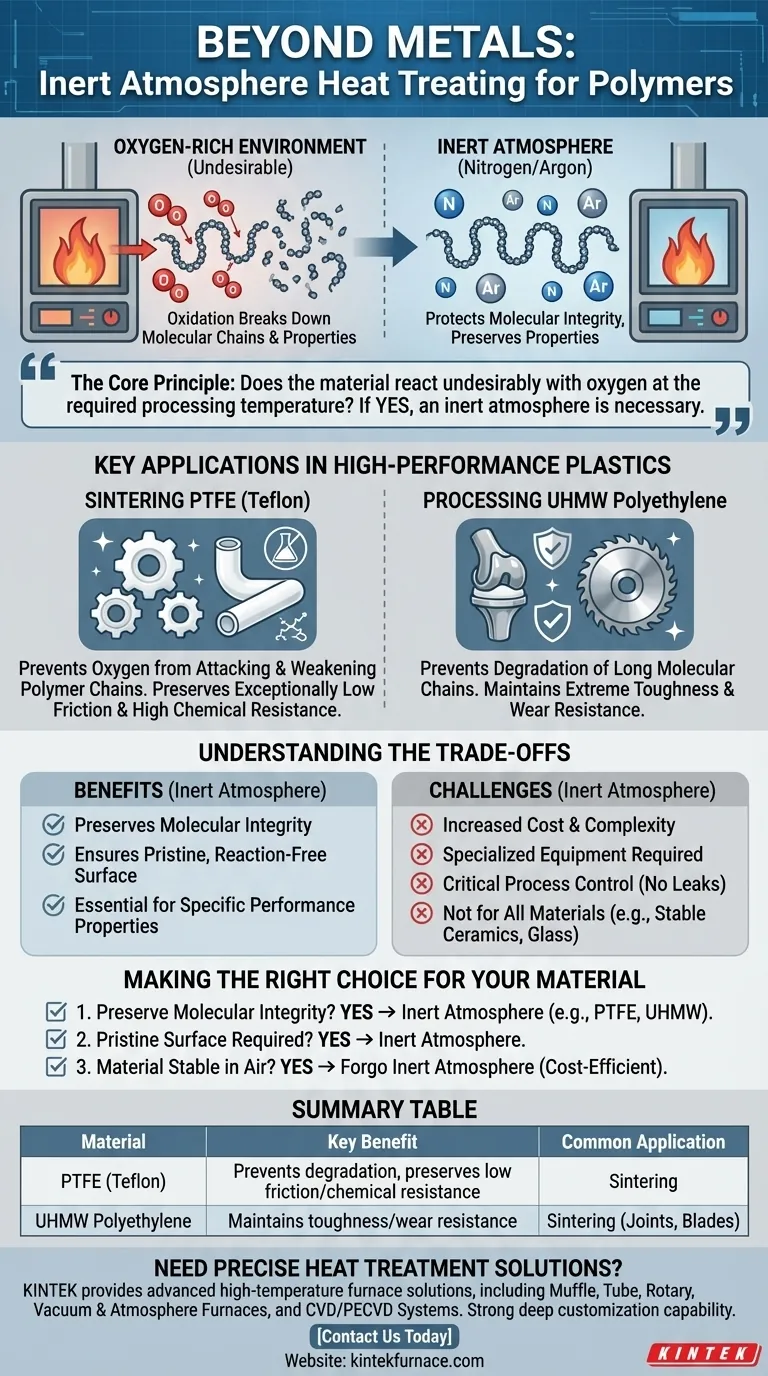

The need for an inert atmosphere is not determined by whether a material is a metal or a plastic, but by a more fundamental question: Does this material react undesirably with oxygen at the required processing temperature? If the answer is yes, an inert atmosphere is necessary to protect its chemical integrity and final properties.

The Core Principle: Preventing Unwanted Chemical Reactions

When we heat treat metals, the primary goal is often to prevent oxidation—rust on steel or a dulling oxide layer on aluminum. The same principle applies to non-metals, though the specific chemical reaction is different.

Oxidation Isn't Just for Metals

Oxidation is a broad chemical term for a reaction involving oxygen that can degrade a material. For certain advanced plastics, exposure to oxygen at high processing temperatures can break down the long molecular chains that give them their strength, low-friction properties, or chemical resistance.

Protecting Molecular Structure

The inert gas, typically nitrogen or argon, displaces the oxygen inside the furnace. This creates a neutral environment that allows heat to be applied without initiating these unwanted and destructive chemical reactions, ensuring the material's core molecular structure remains intact.

Key Applications in High-Performance Plastics

The most common non-metal applications involve sintering, a process where a powdered material is heated below its melting point to fuse it into a solid, functional part.

Sintering PTFE (Teflon)

Polytetrafluoroethylene (PTFE) is known for its exceptionally low friction and high chemical resistance. These properties are a direct result of its stable molecular structure. When PTFE powder is sintered to form parts, an inert atmosphere is critical to prevent oxygen from attacking and weakening its polymer chains, which would compromise its performance.

Processing UHMW Polyethylene

Ultra-High-Molecular-Weight (UHMW) polyethylene is valued for its extreme toughness and wear resistance, used in applications like joint replacements and high-performance saw blades. Heating it in an oxygen-rich environment would degrade its long molecular chains, drastically reducing its strength and durability. An inert atmosphere preserves these properties.

Understanding the Trade-offs

While effective, choosing to use an inert atmosphere is a technical and financial decision that comes with distinct trade-offs.

Increased Cost and Complexity

Utilizing an inert atmosphere requires specialized, well-sealed furnaces and a constant supply of industrial gas like nitrogen or argon. This adds significant cost and operational complexity compared to simply heating a part in an open-air furnace.

Not a Universal Requirement

Many materials are perfectly stable when heated in air. Common ceramics, many types of glass, and certain stable polymers do not react with oxygen at their processing temperatures. For these materials, using an inert atmosphere provides no benefit and is an unnecessary expense.

Process Control is Critical

Maintaining a truly inert environment demands precision. Any leaks in the furnace seals or improper purging cycles can allow oxygen to enter, potentially ruining an entire batch of expensive material. The process requires careful monitoring and control.

Making the Right Choice for Your Material

Your decision should be based on the material's specific chemistry and your end-use requirements.

- If your primary focus is preserving molecular integrity: For materials like PTFE or UHMW whose performance depends on their chemical structure, inert atmosphere treatment is non-negotiable.

- If your primary focus is a pristine, reaction-free surface: If the final part cannot have any surface oxidation or degradation for aesthetic or functional reasons, an inert atmosphere is essential.

- If your primary focus is cost-efficiency with a stable material: If your material is chemically stable in air at the target temperature, forgoing an inert atmosphere is the most practical and economical choice.

Ultimately, understanding your material's reaction to heat and oxygen is the key to making an informed and effective processing decision.

Summary Table:

| Material | Key Benefit of Inert Atmosphere | Common Application |

|---|---|---|

| PTFE (Teflon) | Prevents degradation of polymer chains, preserving low friction and chemical resistance | Sintering processes |

| UHMW Polyethylene | Maintains toughness and wear resistance by protecting long molecular chains | Sintering for joint replacements, saw blades |

Need precise heat treatment solutions for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your material processing with reliable, tailored inert atmosphere systems!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality