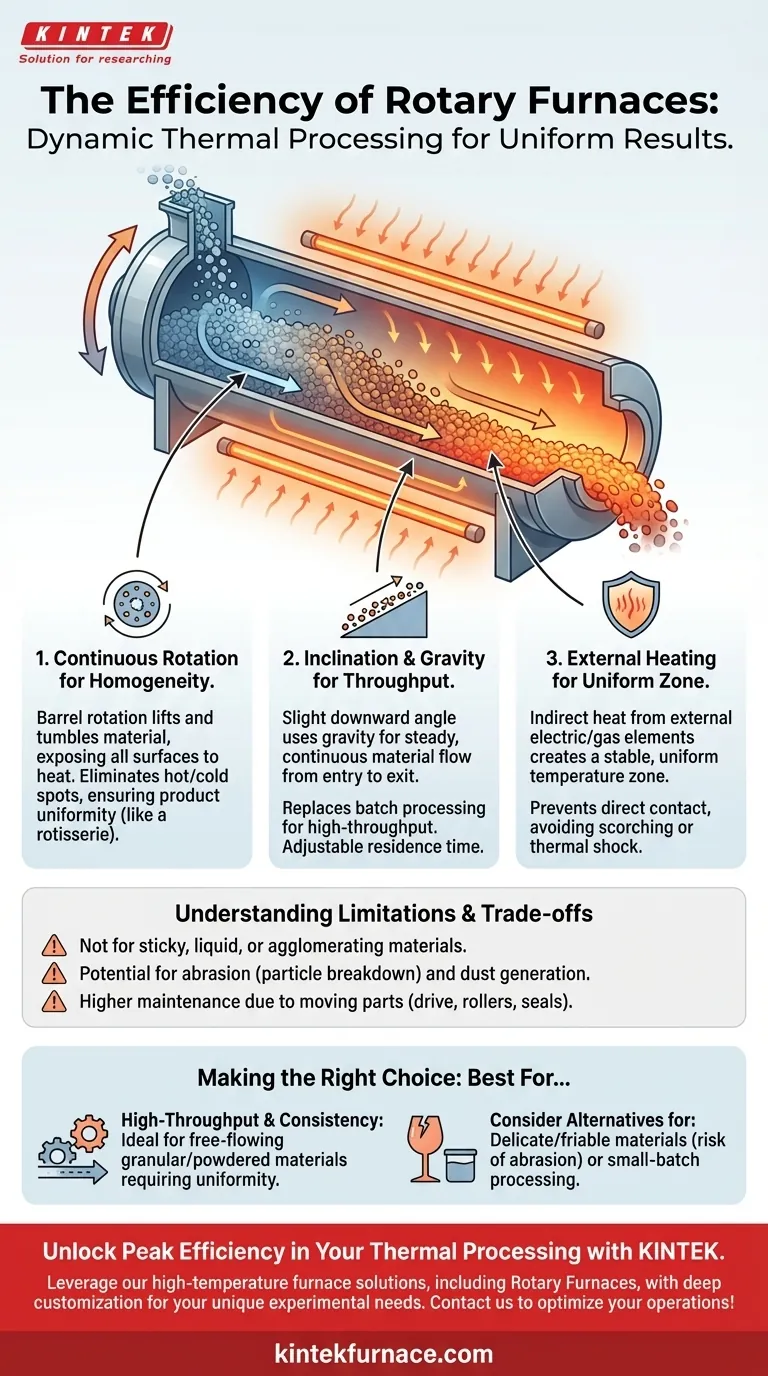

The primary efficiency of a rotary furnace stems from its core design: an inclined, rotating barrel combined with high-quality external heating elements. This combination ensures that the material inside is constantly tumbling and moving forward, which exposes every particle to a consistent temperature. This dynamic process achieves exceptionally uniform heating and allows for continuous, high-throughput operation.

The true advantage of a rotary furnace is not simply the application of heat, but the intelligent way it is transferred. By continuously tumbling material through a precisely controlled heated zone, it maximizes thermal contact with every particle, ensuring a level of uniformity and energy efficiency that static batch methods struggle to match.

The Mechanics of Superior Heat Transfer

To understand the efficiency of a rotary furnace, you must look at how its three key design elements—rotation, inclination, and heating—work in concert.

The Role of Continuous Rotation

The rotation of the furnace barrel is the most critical factor for efficiency. As the barrel turns, it lifts and tumbles the material inside.

This constant mixing action exposes all surfaces of the material to the heat radiating from the furnace walls. This process eliminates hot and cold spots within the material bed, guaranteeing product homogeneity.

Think of it like a rotisserie. By constantly turning, every part of the material receives the same amount of thermal energy, ensuring a uniform and predictable outcome.

The Impact of Inclination and Throughput

Rotary furnaces are set at a slight downward angle. This inclination uses gravity to ensure a steady, controlled flow of material from the entry point to the exit.

This design enables continuous processing, where raw material is constantly fed in one end and finished product is discharged from the other. This is fundamentally more efficient for large-scale industrial production than stop-and-start batch processing.

The speed of rotation and the angle of inclination can be adjusted to precisely control the residence time—how long the material spends inside the furnace—for optimal processing.

Uniform Heating from External Elements

Heat is applied to the outside of the rotating barrel using high-quality electric or gas-fired heating elements. This provides indirect, radiant heat to the material inside.

This method prevents direct contact between the material and the heat source, which is crucial for preventing scorching or thermal shock in sensitive materials. It creates a stable and uniform temperature zone along the length of the barrel.

Understanding the Trade-offs and Limitations

While highly efficient, a rotary furnace is not the universal solution for all thermal processing needs. Understanding its limitations is key to making an informed decision.

Material Suitability

Rotary furnaces excel with free-flowing, granular, or powdered materials. They are less suitable for materials that are sticky, could agglomerate, or are in liquid form, as these can coat the furnace walls or flow uncontrollably.

Potential for Abrasion and Dust

The tumbling action that makes these furnaces so effective can also be a drawback. It can cause attrition—the breakdown of particles—in fragile or abrasive materials.

This same action can also generate significant dust, which may require a separate dust collection system to manage, adding to the overall system complexity and cost.

Mechanical Complexity

Compared to a simple static box furnace, a rotary furnace has more moving parts. The drive system, support rollers, and, critically, the seals at both ends of the barrel require regular inspection and maintenance to ensure reliable operation.

Making the Right Choice for Your Process

Selecting the correct thermal technology depends entirely on your material, throughput requirements, and desired end product.

- If your primary focus is high-throughput and consistency: A rotary furnace is an ideal choice for the continuous processing of granular materials where product uniformity is critical.

- If your primary focus is processing delicate or friable materials: You must carefully evaluate the tumbling action's impact and consider a lower rotation speed or an alternative technology like a static bed furnace.

- If your primary focus is small-batch processing or minimizing capital costs: A simpler batch furnace may be a more practical solution, even if its per-unit thermal efficiency is lower.

Ultimately, the rotary furnace's strength lies in its ability to turn a simple principle—rotation—into a powerful tool for industrial-scale thermal precision.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Design | Inclined, rotating barrel with external heating for constant material movement and uniform heat exposure. |

| Efficiency Factors | Continuous rotation for homogeneous heating, inclination for controlled flow, and external heating for stable temperature zones. |

| Best For | High-throughput processing of free-flowing, granular, or powdered materials requiring product uniformity. |

| Limitations | Not ideal for sticky or liquid materials; potential for abrasion, dust generation, and higher maintenance due to moving parts. |

Unlock Peak Efficiency in Your Thermal Processing with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Whether you need high-throughput processing or tailored designs for granular materials, we deliver reliable, energy-efficient solutions that enhance productivity and ensure uniform results.

Contact us today to discuss how our rotary furnaces and other systems can optimize your operations and drive your success!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating