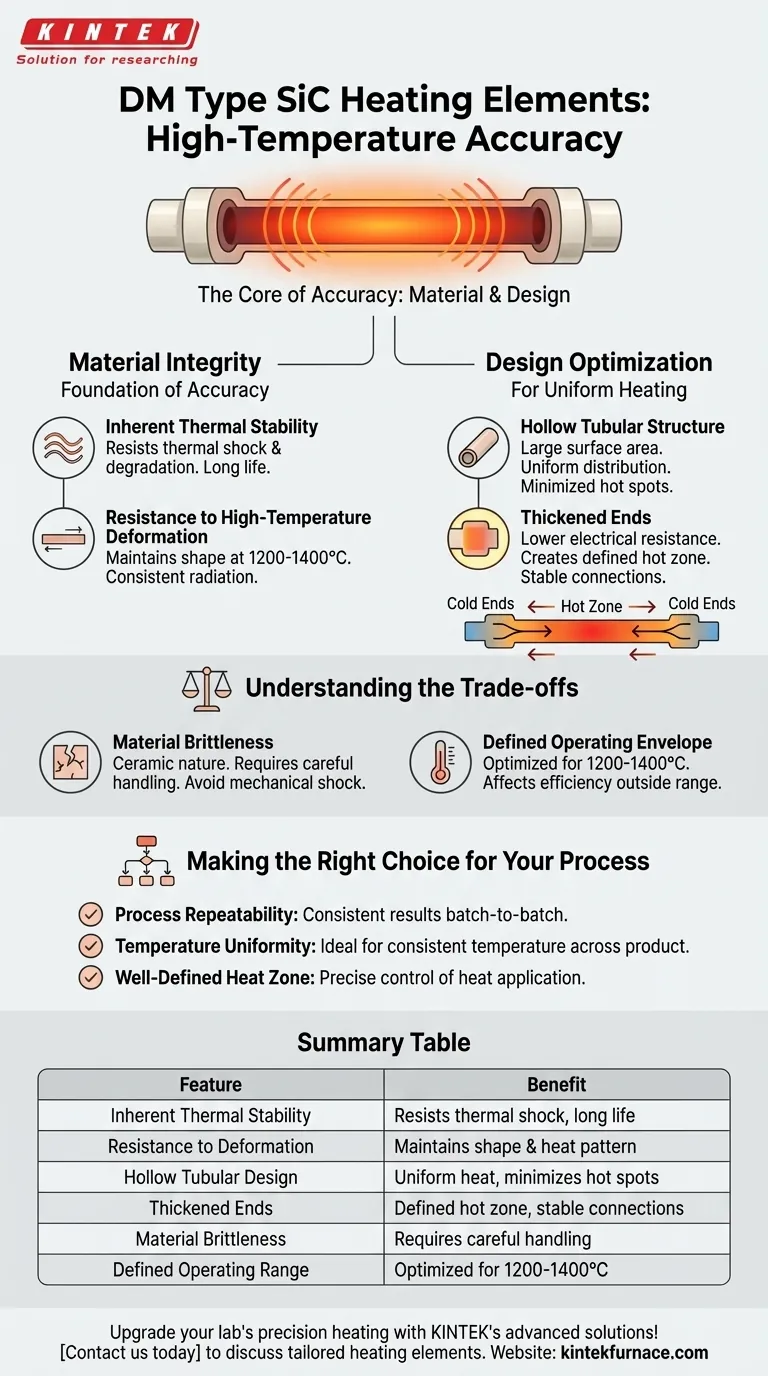

At its core, the suitability of DM Type Silicon Carbide (SiC) heating elements for high-temperature accuracy stems from two factors: the inherent physical stability of the silicon carbide material itself and a specialized design featuring a hollow tube with thickened ends. This combination ensures the element produces consistent, uniform heat without deforming or degrading at extreme operational temperatures.

The key to the DM Type's precision is not just its material, but its geometry. The stable silicon carbide material prevents warping, while the hollow, thick-ended design creates a predictable and uniform heating zone, which is essential for temperature-sensitive processes.

The Foundation of Accuracy: Material Integrity

The performance of any heating element begins with the raw material it is made from. Silicon carbide is chosen specifically for its robust characteristics at high temperatures.

Inherent Thermal Stability

Silicon carbide is highly resistant to thermal shock, meaning it can withstand rapid heating and cooling cycles. This property prevents the development of micro-fractures or degradation over time, leading to a longer and more predictable operational life.

Resistance to High-Temperature Deformation

Crucially, SiC elements do not bend, warp, or deform even at their peak operating temperatures of 1200-1400°C. An element that maintains its shape also maintains its heat radiation pattern, which is the primary source of its accuracy and consistency.

Design Optimization for Uniform Heating

While the material provides stability, the DM Type's specific shape is engineered to deliver that heat with precision and uniformity.

The Hollow Tubular Structure

The element's hollow tube design provides a large, consistent surface area. This allows for uniform heat radiation both outward into the furnace chamber and inward within the tube, contributing to a very even temperature distribution and minimizing hot spots.

The Role of Thickened Ends

The thickened ends are not just for structural support; they are a critical part of the electrical design. These ends have lower electrical resistance than the central heating part. This design forces the majority of the heat to be generated in the slim, central "hot zone," while the ends remain cooler, serving as stable connection points. This creates a clearly defined heating area and prevents temperature fluctuations near the terminals.

Understanding the Trade-offs

No technical solution is without its compromises. Understanding the limitations of DM Type SiC elements is key to using them successfully.

Material Brittleness

While thermally robust, silicon carbide is a ceramic material and is inherently hard and brittle. The elements must be handled with care during installation and maintenance, as mechanical shock or impact can easily cause them to fracture.

Defined Operating Envelope

These elements are optimized for a specific temperature range, typically between 1200°C and 1400°C. Operating significantly below or above this range can impact their efficiency and lifespan, making them unsuitable for processes requiring lower temperatures.

Making the Right Choice for Your Process

Applying this knowledge depends entirely on the specific goal of your high-temperature application.

- If your primary focus is process repeatability: The DM Type's resistance to deformation ensures your heating profile will not change over time, leading to highly consistent results from batch to batch.

- If your primary focus is temperature uniformity: The hollow tubular design provides a large, even radiating surface, making it ideal for applications where a consistent temperature across the entire product is critical.

- If your primary focus is a well-defined heat zone: The use of thickened cold ends creates a distinct hot zone, giving you precise control over where the heat is applied within your furnace.

Ultimately, the DM Type's combination of a stable material and intelligent design delivers the reliable, precise heat necessary for the most demanding applications.

Summary Table:

| Feature | Benefit |

|---|---|

| Inherent Thermal Stability | Resists thermal shock and degradation for long life |

| Resistance to Deformation | Maintains shape and heat radiation pattern at high temps |

| Hollow Tubular Design | Provides uniform heat distribution and minimizes hot spots |

| Thickened Ends | Creates defined hot zone and stable electrical connections |

| Material Brittleness | Requires careful handling to avoid fractures |

| Defined Operating Range | Optimized for 1200-1400°C, ensuring efficiency and lifespan |

Upgrade your lab's precision heating with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior accuracy and efficiency. Contact us today to discuss how our tailored heating elements can enhance your process!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance