Proper maintenance of a vacuum tube furnace is a critical discipline, not just a series of tasks. It primarily involves the regular inspection, cleaning, and upkeep of the vacuum system (pump, seals, and chamber), the gas delivery system, the heating elements, and all associated power supplies. You must always default to the specific procedures and schedules outlined in your equipment’s manufacturer guidelines.

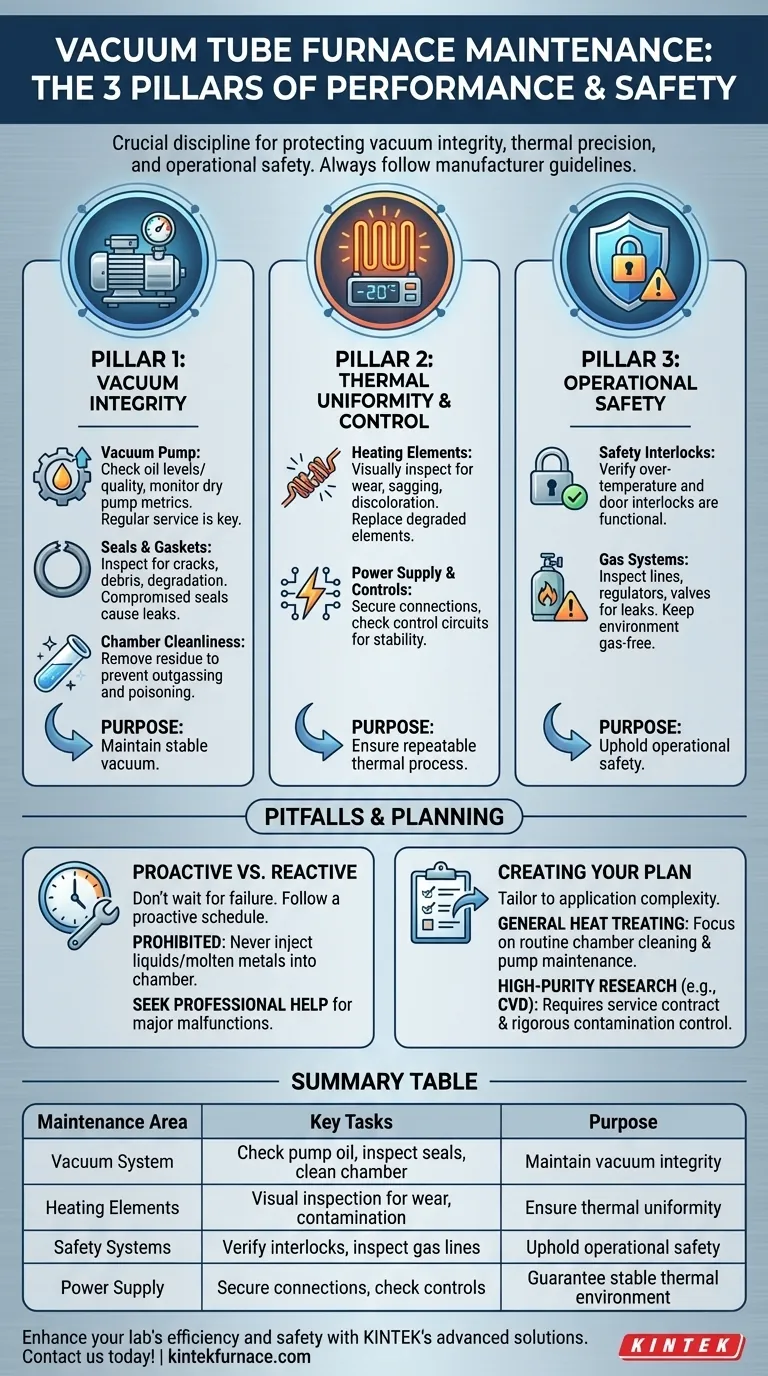

The core purpose of maintenance is not merely to clean the equipment. It is to protect the three pillars of its function: the integrity of the vacuum, the precision of the thermal process, and the safety of the entire operation.

The Foundation: Why Maintenance is Crucial

A vacuum furnace is a system of interdependent, high-performance components. The failure to maintain one part inevitably compromises the others, leading to failed processes, damaged equipment, or safety hazards.

Pillar 1: Maintaining Vacuum Integrity

The entire purpose of the furnace is defeated if it cannot achieve and hold a stable vacuum.

- The Vacuum Pump: This is the heart of the system. Regular checks of oil levels and quality (for oil-based pumps) or monitoring performance metrics (for dry pumps) are essential.

- Seals and Gaskets: All seals on doors, ports, and feedthroughs must be inspected for cracks, debris, or degradation. A compromised seal is the most common source of a vacuum leak.

- Chamber Cleanliness: Any residue or contamination inside the process tube can outgas when heated, poisoning the vacuum atmosphere and preventing the system from reaching its target pressure.

Pillar 2: Ensuring Thermal Uniformity and Control

Accurate and uniform temperature is critical for achieving repeatable results, whether for annealing, sintering, or chemical vapor deposition (CVD).

- Heating Elements: Visually inspect elements for signs of wear, sagging, or discoloration. Contamination from the process can cause them to degrade and fail prematurely.

- Power Supply and Controls: Ensure all connections are secure and that control circuits are functioning. A fluctuating power supply will lead to an unstable thermal environment.

Pillar 3: Upholding Operational Safety

These high-temperature systems operate under extreme conditions and require uncompromising attention to safety protocols.

- Safety Interlocks: Regularly verify that all safety features, such as over-temperature protection and door interlocks, are functional.

- Gas Systems: If you are using process gases, inspect all lines, regulators, and valves for leaks. The furnace's working environment must be kept free of any flammable or corrosive gases.

Common Pitfalls and Considerations

Maintenance is not a one-size-fits-all procedure. Understanding the context of your work is key to avoiding costly mistakes and unnecessary downtime.

The Impact of Application Complexity

Not all vacuum furnaces have the same maintenance demands. A simple furnace for general heat treating is far less demanding than a high-purity CVD system.

- Standard Furnaces: Maintenance is often straightforward, focusing on basic vacuum system health and heating element checks. The operational requirements are less stringent.

- Advanced CVD Furnaces: These demand highly technical maintenance. Process purity is paramount, meaning even minor contamination can ruin results. Maintenance is more frequent, more detailed, and often requires specialized professional skills.

Proactive vs. Reactive Maintenance

Never wait for a problem to occur. A proactive schedule is your best defense.

- Prohibited Actions: Never inject liquids or molten metals directly into the furnace chamber. This causes immediate and catastrophic damage.

- Professional Help: If a significant malfunction or damage occurs, do not attempt a complex repair yourself unless you are a qualified technician. Contact the manufacturer or a certified professional.

Creating Your Maintenance Plan

Your maintenance strategy should be directly tied to your furnace's application and complexity.

- If your primary focus is general heat treating or annealing: Your highest priority is routine chamber cleaning and consistent vacuum pump maintenance.

- If your primary focus is high-purity research (e.g., CVD): You must invest in a formal service contract and develop a rigorous contamination control protocol.

- If you are evaluating a new furnace purchase: Factor the manufacturer's recommended maintenance schedule and its associated costs into your total cost of ownership analysis.

A consistent maintenance routine is the most effective way to guarantee the safety, reliability, and longevity of your vacuum furnace.

Summary Table:

| Maintenance Area | Key Tasks | Purpose |

|---|---|---|

| Vacuum System | Check pump oil, inspect seals, clean chamber | Maintain vacuum integrity |

| Heating Elements | Visual inspection for wear, contamination | Ensure thermal uniformity |

| Safety Systems | Verify interlocks, inspect gas lines | Uphold operational safety |

| Power Supply | Secure connections, check controls | Guarantee stable thermal environment |

Ensure your vacuum tube furnace operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and safety!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability