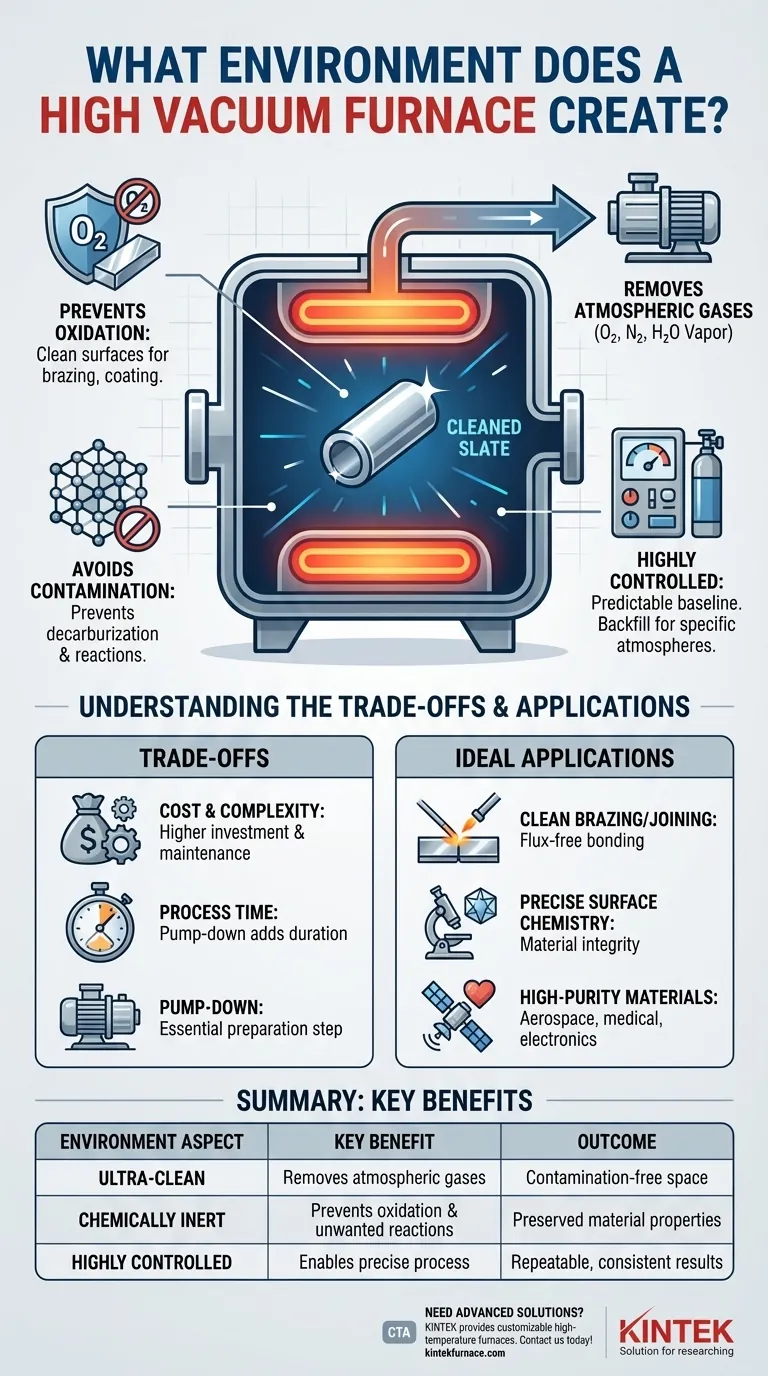

At its core, a high vacuum furnace creates an ultra-clean, chemically inert, and highly controlled environment for processing materials. This is achieved by using a system of pumps to remove nearly all atmospheric gases—primarily oxygen, nitrogen, and water vapor—from a sealed chamber before heating begins. The result is a space free from the contaminants and reactive elements that would otherwise alter the material being treated.

The purpose of a high vacuum furnace is not simply to create an empty space; it is to establish a pristine, non-reactive environment that gives you absolute control over a material's properties by eliminating unwanted atmospheric interference.

The Core Principle: Eliminating Atmospheric Interference

A standard atmosphere is a highly reactive environment, especially at high temperatures. A vacuum furnace works by systematically removing the air and other gases that cause these unwanted reactions.

Preventing Oxidation

The most immediate benefit of removing air is the elimination of oxygen. At high temperatures, oxygen readily reacts with the surface of most metals to form a brittle oxide layer.

By operating in a vacuum, you prevent this oxidation, ensuring the material's surface remains clean and its metallic properties are preserved. This is critical for parts that need to be welded, brazed, or coated after heat treatment.

Avoiding Contamination

Atmosphere contains more than just oxygen. Water vapor, nitrogen, and trace gases can also introduce impurities or cause undesirable chemical reactions at high temperatures.

For example, carbon in steel can react with trace amounts of oxygen or water vapor, leading to decarburization—a loss of carbon from the surface that reduces hardness and fatigue strength. A vacuum environment prevents this, maintaining the material's intended composition.

Creating a Stable, Controlled Environment

A vacuum provides a predictable and repeatable baseline. By first removing all atmospheric variables, you gain precise control over the treatment process.

If a specific atmosphere is needed, pure, high-quality gas can be backfilled into the furnace. This allows for processes that require a specific partial pressure of a gas like nitrogen or argon, giving you the benefits of a controlled atmosphere without the risk of contamination from air.

Understanding the Trade-offs

While powerful, a vacuum environment is not the default solution for all thermal processing. It's essential to understand its specific role and limitations.

It's About Control, Not Emptiness

The goal isn't always a perfect vacuum. Many advanced processes involve backfilling the furnace with a specific gas after the initial vacuum has been achieved. The vacuum's primary job is to "clean the slate" before introducing a precisely controlled element.

Cost and Complexity

High vacuum furnaces are significantly more complex than standard atmospheric furnaces. They require robust pumping systems, high-integrity seals, and sophisticated controls to achieve and maintain low pressures. This translates to higher initial investment and maintenance costs.

Process Time

Achieving a high vacuum can be time-consuming. The "pump-down" time before the heating cycle can begin adds to the overall process duration compared to simply heating a part in an atmospheric furnace.

Making the Right Choice for Your Goal

Selecting the right furnace environment depends entirely on the desired outcome for your material. A vacuum provides an unparalleled level of control when surface chemistry and purity are paramount.

- If your primary focus is achieving clean, flux-free brazing or joining: A high vacuum is essential to prevent oxide layers that interfere with the flow and bonding of the filler material.

- If your primary focus is maintaining the precise surface chemistry of a part: The inert vacuum environment prevents unwanted reactions like oxidation and decarburization during heat treatment.

- If your primary focus is producing the highest purity materials: A vacuum furnace ensures a contamination-free environment critical for medical implants, aerospace components, and electronic materials.

Ultimately, choosing a vacuum environment is a decision to prioritize material integrity and process control above all else.

Summary Table:

| Environment Aspect | Key Benefit |

|---|---|

| Ultra-Clean | Removes atmospheric gases like oxygen, nitrogen, and water vapor |

| Chemically Inert | Prevents oxidation, decarburization, and contamination |

| Highly Controlled | Enables precise process control and repeatability |

Need a high vacuum furnace for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your material processing with our tailored solutions!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance