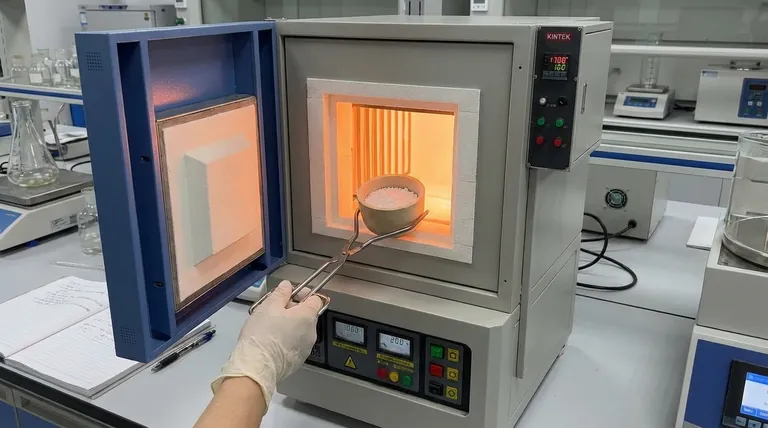

The high-temperature muffle furnace acts as the catalyst for the critical phase transition of Yttrium Oxide, converting it from a raw precursor into a functional active layer. By providing a stable environment around 500 °C, the furnace drives the dehydration, decomposition, and subsequent recrystallization required to turn amorphous materials into a polycrystalline film.

The furnace provides the specific activation energy needed to reorganize the atomic structure of the material. This thermal process dictates the final crystal orientation, which is directly responsible for the material's ability to form conductive filaments effectively.

The Mechanism of Thermal Transformation

Driving Chemical Changes

The synthesis begins with a precursor material that is chemically unstable and amorphous. The muffle furnace supplies the heat necessary to trigger dehydration and decomposition.

This stage removes volatile components from the precursor. It ensures that only the desired Yttrium Oxide chemical structure remains on the substrate.

From Amorphous to Polycrystalline

Once impurities are removed, the sustained heat forces the remaining atoms to arrange themselves into an ordered lattice. This is the shift from an amorphous state to a polycrystalline structure.

Without this thermal drive, the material would lack the structural definition required for high-performance electronics.

Controlling Crystal Orientation

The specific goal of this heating process is not random crystallization, but preferential growth.

In the case of Yttrium Oxide, the furnace promotes the formation of crystals with a (222) orientation. This specific structural alignment is the target outcome of the 500 °C treatment.

Impact on Device Functionality

Enabling Conductive Filaments

The ultimate purpose of the active layer is to facilitate electronic activity within a device. The quality of the crystallization determines how easily conductive filaments can form.

A well-crystallized polycrystalline structure lowers the energy barrier for these filaments. This results in more reliable and consistent switching behavior in the final electronic component.

Understanding the Process Variables

The Role of Temperature Stability

Precisely maintaining the temperature at 500 °C is critical. Deviations can lead to incomplete crystallization or mixed crystal orientations.

If the temperature is insufficient, the material may remain partially amorphous, degrading its electrical properties.

Structural Uniformity vs. Mechanical Action

Unlike other synthesis methods that require mechanical agitation (such as rocking furnaces used for Indium-Selenium alloys), this process relies on static, uniform heat.

The muffle furnace creates an environment where chemical bonding, rather than mechanical mixing, drives the structural uniformity.

Optimizing Synthesis for Electronic Reliability

To ensure the highest quality Yttrium Oxide active layers, align your thermal processing with your specific performance goals:

- If your primary focus is Structural Integrity: Ensure the furnace maintains a strictly controlled 500 °C profile to drive complete dehydration and prevent amorphous defects.

- If your primary focus is Electrical Switching: Verify that the thermal duration is sufficient to achieve the (222) preferential crystal orientation, as this directly influences filament formation.

The muffle furnace is not just a heat source; it is the tool that defines the structural DNA of your electronic material.

Summary Table:

| Stage | Process Type | Physical/Chemical Transformation |

|---|---|---|

| Precursor Treatment | Dehydration & Decomposition | Removal of volatile components and impurities |

| Phase Transition | Crystallization | Shift from amorphous state to ordered polycrystalline lattice |

| Structural Control | Preferential Growth | Alignment of atoms into the critical (222) crystal orientation |

| Final Outcome | Functionalization | Creation of layers capable of forming stable conductive filaments |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect (222) crystal orientation in Yttrium Oxide requires more than just heat; it requires the absolute thermal stability and uniformity found in KINTEK’s high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research or production parameters.

Whether you are developing next-generation electronic components or advanced polycrystalline films, KINTEK provides the reliability you need to ensure consistent filament formation and device performance. Contact us today to discuss your unique needs and see how our expertise can optimize your thermal processing workflow.

References

- Yoonjin Cho, Jaewon Jang. Effect of Electrochemically Active Top Electrode Materials on Nanoionic Conductive Bridge Y2O3 Random-Access Memory. DOI: 10.3390/nano14060532

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What core roles does a muffle furnace play in the crystal growth of NaNbO3:Pr3+? Enhance Your Material Synthesis

- What are the primary applications of a high-temperature muffle furnace in biomass fuel evaluation? Optimize Energy Data

- What role do muffle furnaces play in materials research? Unlock Precise Heat Treatment for Your Lab

- How is a laboratory Muffle furnace utilized in the heat treatment of DP steel? Optimize Martensite & Strength

- What is the primary function of a muffle furnace in W-TiO2 crystallization? Optimize Nanopowder Performance

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- What role does a high-temperature muffle furnace play in g-C3N4 catalyst synthesis? Precision Pyrolysis Solutions

- What is the function of a high-temperature muffle furnace? Master Polycrystalline MgSiO3 and Mg2SiO4 Synthesis