In essence, zirconia sintering is a high-temperature thermal treatment that transforms a soft, chalk-like milled zirconia restoration into its final, dense, and exceptionally strong state. This carefully controlled firing process is what gives zirconia its well-known durability and esthetic properties, converting it from a fragile "green body" into a clinically viable prosthesis.

Sintering is not merely heating; it is a fundamental material transformation. The process eliminates porosity and fuses ceramic particles together, causing predictable shrinkage while unlocking the material's inherent strength and final translucency. The success of any zirconia restoration is defined by the precision of this cycle.

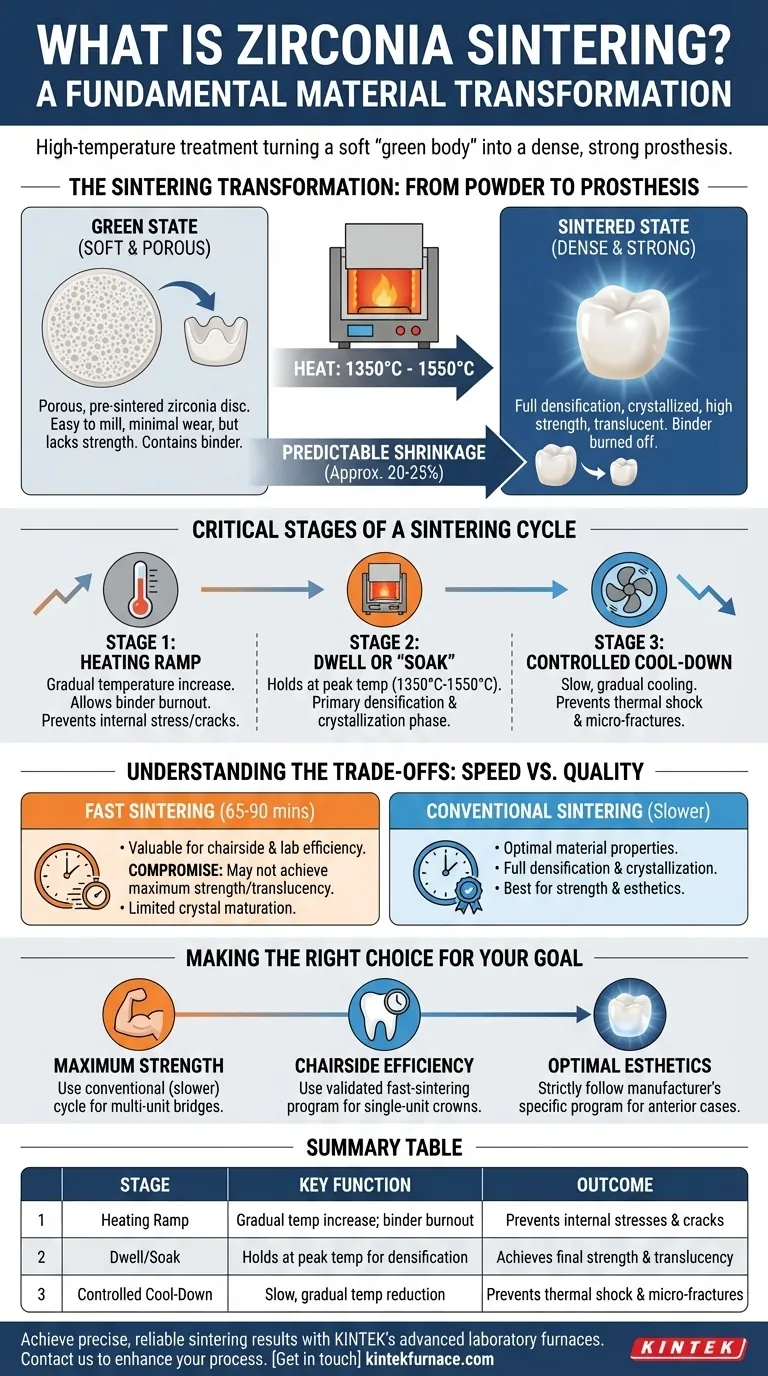

From Powder to Prosthesis: The Sintering Transformation

To understand sintering, you must first understand the material's initial state. The process is a journey from a weak, porous object to a fully densified, monolithic structure.

The "Green State" Starting Point

Zirconia restorations are not milled from a solid, dense block. They are machined from a pre-sintered disc, often called the "green state" or "white state."

This disc consists of zirconia powder that has been pressed together with a binder. In this form, the material is soft enough to be milled easily and quickly with minimal wear on tooling, but it possesses no meaningful strength.

The Role of Heat: Densification and Crystallization

The sintering furnace applies a precise thermal cycle to enact two critical changes:

- Densification: As the temperature rises, the binder is cleanly burned away. The zirconia particles then begin to fuse at their contact points, eliminating the voids between them and pulling the structure together into a dense mass.

- Crystallization: Heat controls the growth and arrangement of the zirconia crystals. This final crystal structure is what dictates the material's key physical properties, including its flexural strength and its level of translucency.

The Result: Predictable Shrinkage

A direct consequence of densification is shrinkage. As the voids are eliminated, the entire restoration shrinks in volume by approximately 20-25%.

This is not a flaw but a planned and predictable part of the process. The design software (CAD) automatically scales the restoration up before milling to precisely compensate for this shrinkage, ensuring the final sintered part is the exact size required.

The Critical Stages of a Sintering Cycle

A typical sintering program is not a simple heat-and-cool process. It is a multi-stage profile where every phase has a specific purpose.

Stage 1: The Heating Ramp

The furnace temperature is increased gradually. A controlled ramp rate is critical to allow the binder to burn out completely without creating internal stresses or cracks in the restoration. Rushing this stage can lead to a compromised final part.

Stage 2: The Dwell or "Soak"

The furnace holds the restoration at a peak temperature, typically between 1350°C and 1550°C. This is the primary sintering phase where full densification and crystallization occur. The duration of this "soak" is a key variable that influences the final properties.

Stage 3: The Controlled Cool-Down

Cooling the restoration too quickly can induce thermal shock, creating micro-fractures that weaken the final prosthesis. A slow, controlled cooling phase is just as important as the heating phase for ensuring structural integrity and stability.

Understanding the Trade-offs: Speed vs. Quality

Modern furnaces offer a range of sintering cycles, forcing a choice between outright speed and optimal material properties.

The Allure of Fast Sintering

Many furnaces now feature "fast" or "speed" sintering programs that can complete a cycle in as little as 65-90 minutes. This is highly valuable for chairside applications and improving lab efficiency.

The Potential Compromise

These accelerated cycles are a compromise. While they produce clinically acceptable results with compatible zirconia materials, they may not achieve the same maximum flexural strength or highest level of translucency as a conventional, slower cycle. The extremely rapid heating and cooling can limit full crystal maturation.

The Importance of a Clean Environment

Sintering furnaces must provide an impeccably clean environment. High-purity heating elements, such as silicon molybdenum rods, are used to prevent any contaminants from being released. Contamination can lead to discoloration and a weakening of the final restoration.

Making the Right Choice for Your Goal

The ideal sintering cycle is not one-size-fits-all; it depends entirely on the zirconia material used and the desired clinical outcome.

- If your primary focus is maximum strength: For multi-unit bridges or cases requiring the highest durability, use the manufacturer's recommended conventional (slower) sintering cycle to ensure full densification.

- If your primary focus is chairside efficiency: A validated fast-sintering program is an excellent choice for single-unit crowns, provided you use a zirconia material specifically approved for that cycle.

- If your primary focus is optimal esthetics: For highly translucent materials used in the anterior, strictly follow the manufacturer's specific program, as it is fine-tuned to achieve the target level of light transmission.

Ultimately, mastering zirconia sintering means understanding that you are not just running a machine, but precisely controlling a material's transformation to achieve a predictable and successful outcome.

Summary Table:

| Sintering Stage | Key Function | Outcome |

|---|---|---|

| Heating Ramp | Gradual temperature increase; binder burnout | Prevents internal stresses and cracks |

| Dwell/Soak | Holds at 1350°C–1550°C for densification | Achieves final strength and translucency |

| Controlled Cool-Down | Slow, gradual temperature reduction | Prevents thermal shock and micro-fractures |

Achieve precise, reliable sintering results with KINTEK's advanced laboratory furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide dental labs and research facilities with high-temperature solutions like our Muffle and Vacuum/Atmosphere Furnaces. Our strong deep customization capability ensures your sintering cycles meet the exact requirements of your zirconia materials. Contact us today to discuss how we can enhance your sintering process and deliver consistent, high-quality prostheses. Get in touch via our Contact Form

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features of ceramic dental furnaces? Precision Automation for Aesthetic Restorations

- What is the function of sintering furnaces? Transform Powders into Dense, Strong Components

- Why is proper temperature important in the sintering process? Unlock Optimal Material Properties

- What are some differences between pressing furnaces and porcelain furnaces? Choose the Right Dental Lab Equipment

- What is the general procedure for using a dental lab equipment furnace? A Step-by-Step Guide

- What are the three critical functions performed by a dental porcelain furnace? Achieve Precision in Dental Restoration

- What are the two main types of dental porcelain furnace systems? Choose the Right One for Your Lab

- What maintenance does a dental zirconia sintering furnace require? Ensure Peak Performance and Restoration Quality