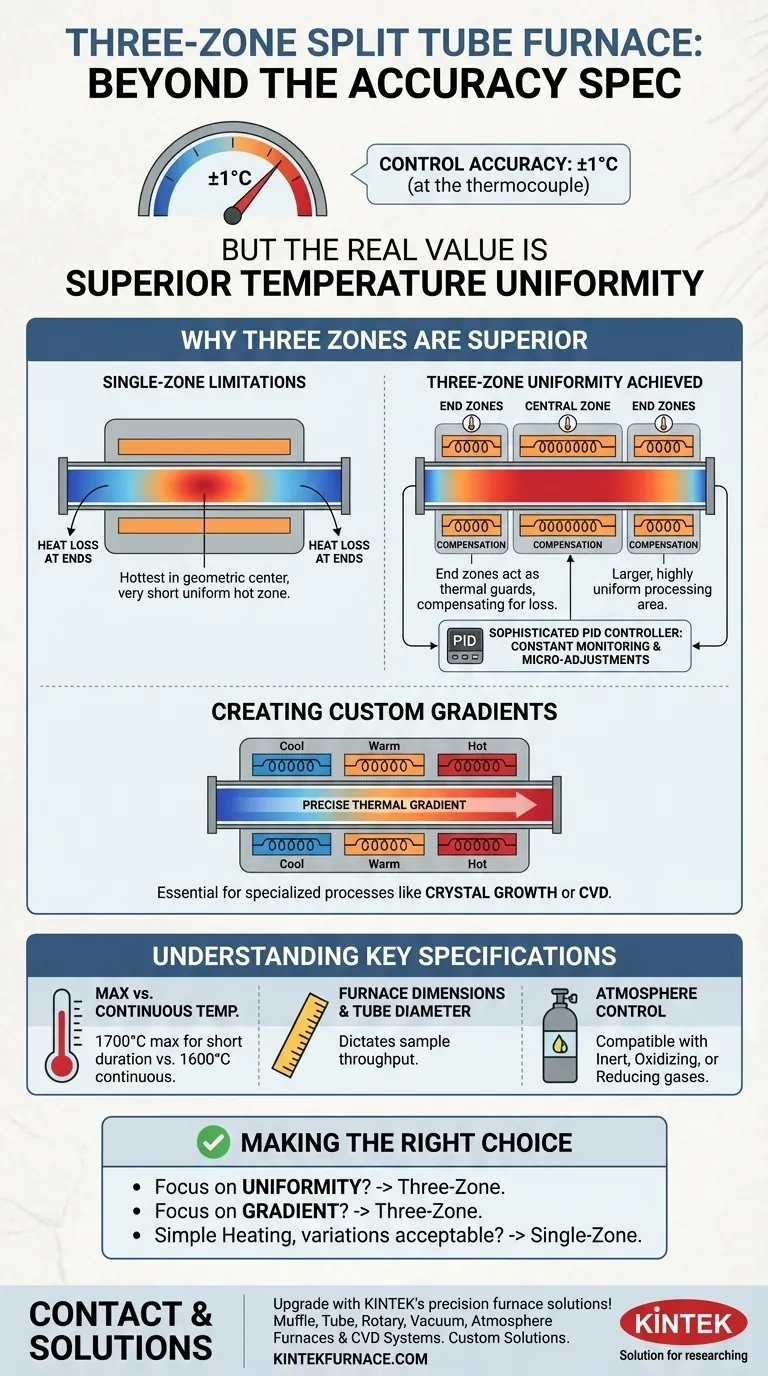

In a standard three-zone split tube furnace, the temperature accuracy of the control system is typically ±1℃. This figure refers to the precision with which the furnace's controller can maintain a set temperature at the specific point of its thermocouple. However, the true value of a three-zone design lies not just in this accuracy, but in its ability to create a highly uniform temperature environment across a significant length of the tube.

While the control accuracy is an impressive ±1℃, the core benefit of a three-zone furnace is achieving superior temperature uniformity. This design overcomes the inherent heat loss at the ends of the furnace, ensuring your sample experiences a consistent temperature across its entire volume.

Why Three Zones Are Superior to One

A three-zone furnace is specifically engineered to solve a fundamental problem in thermal processing: heat loss. Understanding this principle is key to appreciating its function.

The Limitation of Single-Zone Furnaces

A standard single-zone furnace is hottest in its geometric center. Temperature naturally drops off toward the ends of the tube, where heat escapes into the surrounding environment. This creates a very short, truly uniform hot zone, which can be a significant limitation.

Achieving True Temperature Uniformity

A three-zone furnace divides the heating element into a central zone and two end zones. Each zone has its own independent thermocouple and controller.

The two end zones are programmed to compensate for natural heat loss, effectively acting as thermal guards. This ensures the central zone maintains a highly uniform temperature across its entire length, providing a much larger and more stable processing area.

Creating Custom Temperature Gradients

Beyond uniformity, this design offers immense flexibility. You can intentionally program different temperatures in each zone to create a precise thermal gradient along the tube, which is essential for specialized processes like crystal growth or chemical vapor deposition (CVD).

What "±1℃ Accuracy" Really Means in Practice

The stated accuracy of ±1℃ is a measure of the control system's performance, but it's not the complete picture of your sample's thermal environment.

Control Accuracy vs. Thermal Uniformity

Control accuracy (±1℃) is how well the furnace holds the setpoint temperature as measured by its own internal controller. Thermal uniformity describes how little the temperature varies across the entire length of the heated zone. A three-zone furnace is designed to maximize this uniformity.

The Role of the PID Controller

This accuracy is achieved by a sophisticated PID (Proportional-Integral-Derivative) controller. It constantly monitors the thermocouple reading and makes micro-adjustments to the power supplied to the heating elements, preventing temperature overshoots and undershoots.

Understanding the Key Specifications

When evaluating a furnace, looking beyond the accuracy figure is critical. The following specifications have a direct impact on performance and suitability for your work.

Maximum vs. Continuous Operating Temperature

These are two distinct ratings. The maximum temperature (e.g., 1700°C) is a peak rating for very short durations. The continuous operating temperature (e.g., 1600°C) is the highest temperature the furnace can safely maintain for extended periods without damaging the heating elements.

Furnace Dimensions and Tube Diameter

The size of the furnace, including its heated length and the diameter of the process tube it can accommodate, dictates your sample throughput. Larger dimensions require more power to maintain uniformity.

Atmosphere Control

A key function of a tube furnace is processing samples in a controlled atmosphere. Ensure the furnace is compatible with your required gas flows, whether they are inert (like Argon), oxidizing (like air), or reducing (like Hydrogen mixtures).

Making the Right Choice for Your Goal

Use these guidelines to determine the best approach for your specific application.

- If your primary focus is achieving the highest possible temperature uniformity for a sensitive material: A three-zone furnace is the correct choice, as it is specifically designed to create a large, stable hot zone.

- If your primary focus is running a process that requires a specific thermal gradient: The independent control of a three-zone furnace provides the necessary flexibility to program complex temperature profiles.

- If your primary focus is simple heating where slight temperature variation at the ends is acceptable: A more cost-effective single-zone furnace may be sufficient for your needs.

Ultimately, selecting the right furnace is about matching the equipment's capabilities to your specific thermal processing requirements.

Summary Table:

| Specification | Details |

|---|---|

| Temperature Accuracy | ±1°C at the thermocouple point |

| Key Benefit | Superior temperature uniformity across the tube length |

| Zone Control | Independent control for central and end zones |

| Applications | Crystal growth, CVD, and other processes requiring precise thermal gradients |

| Atmosphere Compatibility | Inert, oxidizing, and reducing gases |

| Operating Temperatures | Maximum and continuous ratings (e.g., 1700°C max, 1600°C continuous) |

Upgrade your lab's thermal processing with KINTEK's precision furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior temperature control and uniformity. Contact us today to discuss how our tailored solutions can optimize your research and production efficiency!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity