In short, a muffle furnace is significant in pharmaceutical R&D for its ability to provide a precisely controlled, high-temperature environment. This capability is essential for analytical testing, quality control of raw materials and final products, and for synthesizing novel materials used in advanced drug delivery systems.

The core value of a muffle furnace is not just heat, but purity of process. By separating the material from the heating elements and combustion byproducts, it ensures that analytical results are accurate and that newly created materials are free from contamination.

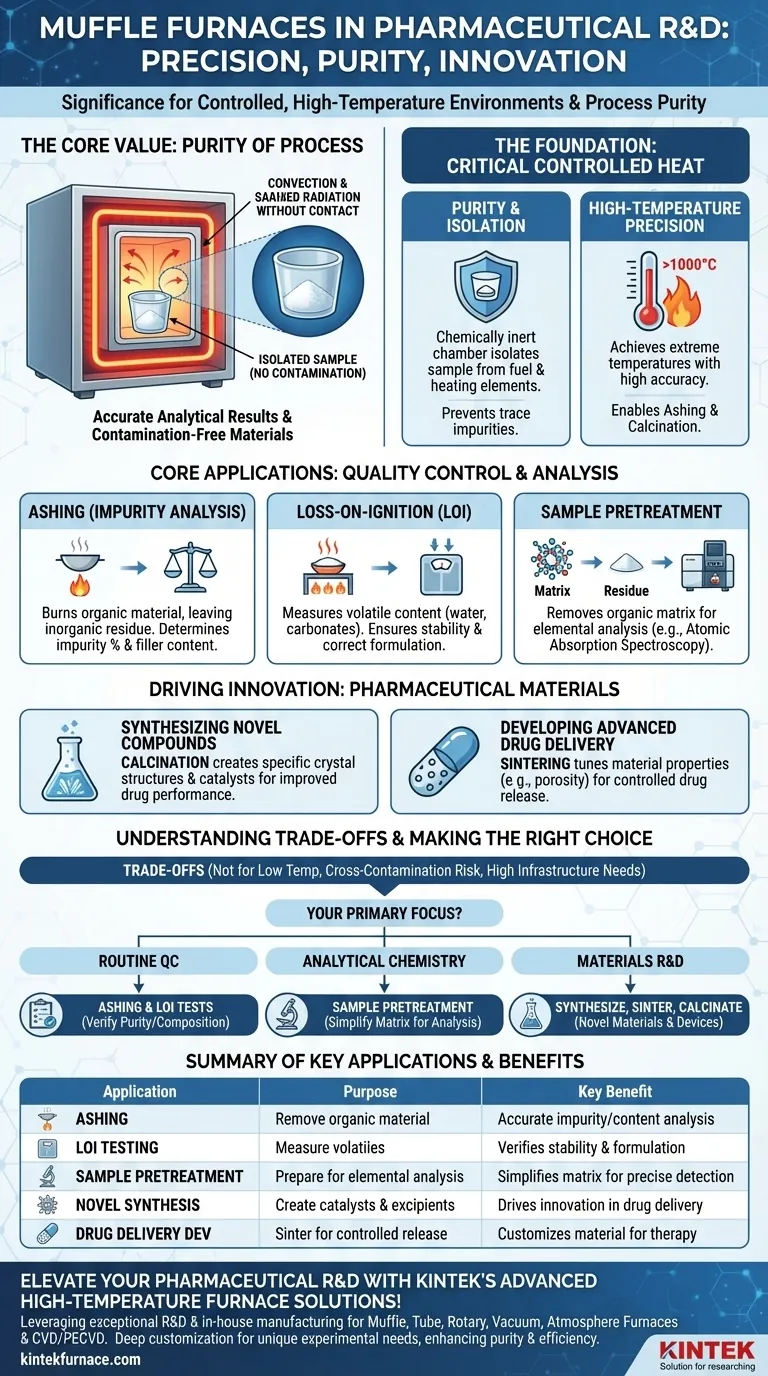

The Foundation: Why Controlled Heat is Critical

A muffle furnace is a specialized high-temperature oven. The term "muffle" refers to the insulated inner chamber that isolates the sample from the direct heat source.

Purity and Isolation

The sample is heated by convection and radiation within a chemically inert chamber. This prevents contamination from the fuel or electrical heating elements, which is non-negotiable in pharmaceutical analysis where trace impurities can invalidate results.

High-Temperature Precision

These furnaces can achieve and maintain extremely high temperatures, often exceeding 1000°C, with high accuracy. This allows for thermal processes like ashing or calcination that are impossible in standard laboratory ovens.

Core Applications in Quality Control and Analysis

In pharmaceuticals, quality is paramount. Muffle furnaces are workhorses for the quantitative tests that verify the composition and purity of materials.

Ashing for Impurity and Content Analysis

Ashing is the process of burning away all organic material in a sample to leave behind only the inorganic, non-combustible residue (ash).

This is a critical quality control step. By weighing the sample before and after ashing, analysts can precisely determine the percentage of inorganic fillers or impurities in a drug substance, which must fall within strict regulatory limits.

Loss-on-Ignition (LOI) Testing

LOI is a related technique used to determine the amount of volatile material in a sample. The sample is heated at a specific high temperature, and the weight lost is measured.

This can quantify the content of water, carbonates, or other volatile components. This data is vital for ensuring the stability and correct formulation of pharmaceutical products.

Sample Pretreatment for Elemental Analysis

Before a sample can be analyzed by advanced techniques like atomic absorption spectroscopy (AAS), it often needs to be pretreated.

Using a muffle furnace to ash the sample removes the complex organic matrix. This leaves a simple inorganic residue that is easily dissolved, allowing for accurate measurement of trace metals or other elements.

Driving Innovation in Pharmaceutical Materials

Beyond routine testing, muffle furnaces are indispensable tools for creating the next generation of medicines and medical devices.

Synthesizing Novel Compounds

Processes like calcination (heating a solid to high temperatures in the absence of air) are used to create specific crystal structures or activate materials.

This is crucial in developing catalysts, advanced ceramics, or novel excipients (inactive ingredients) that can improve a drug's performance.

Developing Advanced Drug Delivery Systems

Researchers use furnaces to create and test new materials for drug delivery, such as biocompatible polymers or porous inorganic materials.

The furnace's controlled environment is used to sinter these materials, tuning their properties (like porosity) to control how a drug is released in the body over time.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool with specific limitations.

Not Suited for Low-Temperature Applications

For simple drying, sterilization, or processes below ~250°C, a standard laboratory oven is more energy-efficient and appropriate. Muffle furnaces are designed for high-temperature applications.

Risk of Cross-Contamination

If not meticulously maintained, residue from previous samples can remain in the furnace chamber. This can volatilize during a subsequent run and contaminate a new sample, leading to inaccurate analytical results.

Requires Significant Infrastructure

Muffle furnaces consume a large amount of electricity and generate substantial external heat. They require dedicated bench space, proper ventilation, and robust electrical circuits, making them a significant piece of lab infrastructure.

Making the Right Choice for Your Goal

Understanding the role of the furnace allows you to apply it correctly to your specific objective.

- If your primary focus is routine quality control: Use the furnace for ashing and LOI tests to quantify the inorganic and volatile content of raw materials and finished products, ensuring they meet purity specifications.

- If your primary focus is analytical chemistry: Use the furnace as a sample pretreatment tool to destroy the organic matrix, simplifying the sample for accurate elemental analysis.

- If your primary focus is materials R&D: Use the furnace's high-temperature capabilities to synthesize, sinter, and calcinate novel materials for next-generation drug delivery systems and biocompatible devices.

Ultimately, the muffle furnace serves as both a gatekeeper of quality and an engine for innovation within the precise world of pharmaceutical science.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Ashing | Remove organic material to analyze inorganic residue | Ensures accurate impurity and content analysis |

| Loss-on-Ignition (LOI) Testing | Measure volatile components in samples | Verifies product stability and formulation |

| Sample Pretreatment | Prepare samples for elemental analysis | Simplifies matrix for precise metal detection |

| Synthesis of Novel Compounds | Create catalysts and excipients via calcination | Drives innovation in drug delivery systems |

| Advanced Drug Delivery Development | Sinter materials for controlled drug release | Customizes material properties for therapeutic use |

Elevate your pharmaceutical R&D with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems tailored for precise thermal processing. Our deep customization capabilities ensure your unique experimental needs are met, enhancing purity and efficiency in drug analysis and material synthesis. Contact us today to discuss how our solutions can drive your innovations forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How to keep samples in muffle furnace? A Step-by-Step Guide for Safe & Accurate Results

- What temperature range can box furnaces reach? Achieve 1800°C for Precise Thermal Processing

- How is a laboratory Muffle furnace utilized in the heat treatment of DP steel? Optimize Martensite & Strength

- What restrictions apply to materials placed in the muffle furnace? Ensure Safe, High-Temperature Processing

- What are the key applications of a muffle furnace? Essential for Pure Heat Treatment and Analysis

- What role does a laboratory high-temperature box furnace play in fire impact experiments for steel? | KINTEK

- How does a high-temperature laboratory muffle furnace affect material properties? Transform Anodic Oxide Films Fast

- Why is controlled and consistent heating important in a muffle furnace? Ensure Reliable Results in Your Lab