Fundamentally, a rotary furnace is a cylindrical, rotating chamber used to heat, melt, and process materials, most notably scrap metal and industrial byproducts. The furnace is mounted at a slight angle and rotates along its horizontal axis, causing the materials inside to tumble and mix continuously. This dynamic action ensures highly efficient and uniform heat transfer.

The defining advantage of a rotary furnace isn't just its ability to generate high temperatures, but its method of achieving them. The constant rotation guarantees that every part of the material is exposed to the heat source, leading to superior mixing and more consistent melting compared to static furnaces.

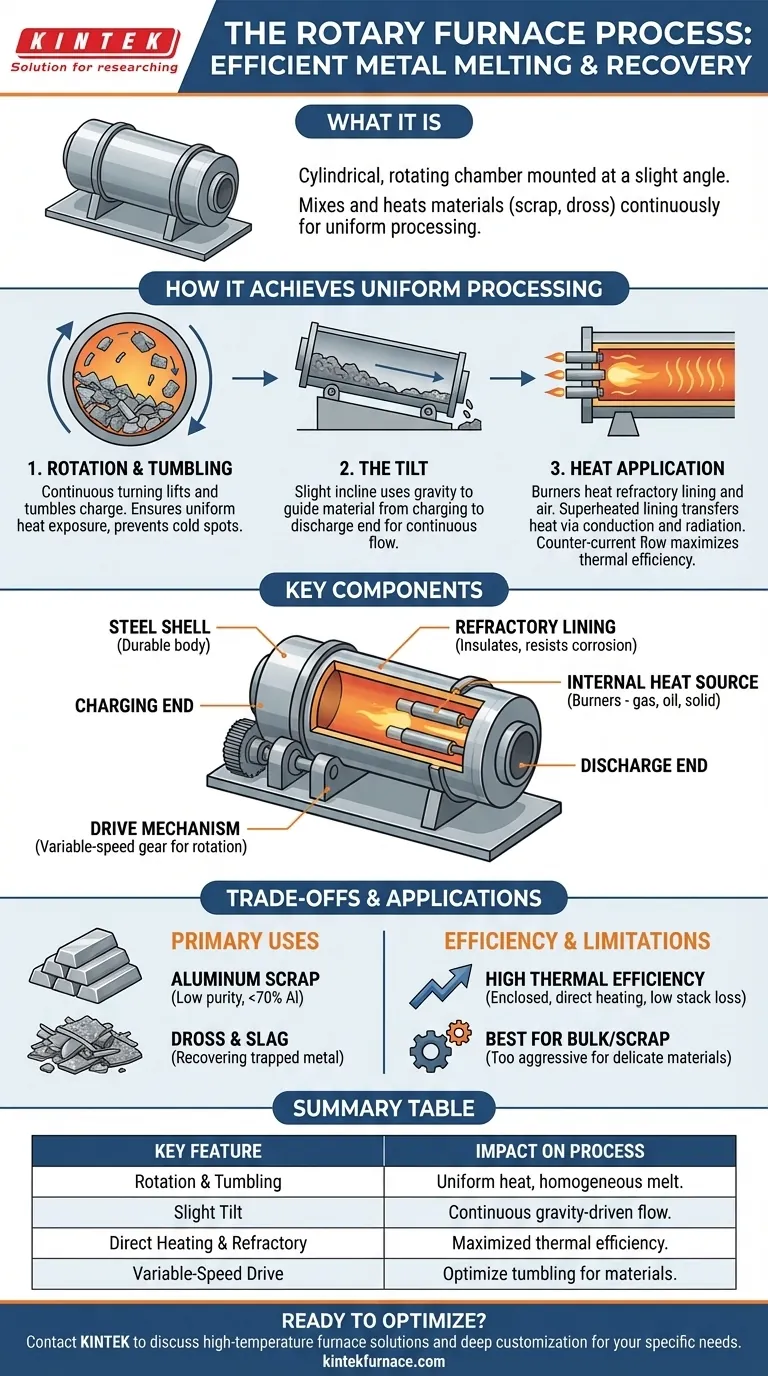

How a Rotary Furnace Achieves Uniform Processing

The effectiveness of the rotary furnace process comes from the interplay of three core mechanical and thermal principles.

The Principle of Rotation and Tumbling

The primary action is the slow rotation of the furnace body. As the cylindrical drum turns, it lifts the charge material (the scrap or dross being processed) partway up the wall before it tumbles back down.

This continuous tumbling is critical. It constantly exposes new surfaces of the material to the heat and prevents the formation of hot or cold spots, ensuring a homogenous melt.

The Role of the Tilt

Rotary furnaces are installed with a slight tilt. This incline uses gravity to slowly guide the material from the charging end of the furnace to the discharge end.

The combination of rotation and tilt creates a slow, predictable flow through the furnace, which allows for continuous processing and uniform treatment of the entire batch.

The Method of Heat Application

Heat is typically generated by powerful burners that can use gas, liquid, or pulverized solid fuel. These burners heat the refractory lining on the upper part of the furnace.

As the furnace rotates, this superheated lining cycles underneath the charge, transferring heat directly through conduction and radiation. In many designs, the hot exhaust gases are also directed to flow over the material, often in the opposite direction of the material's movement (a "counter-current" flow) to maximize thermal efficiency.

Deconstructing the Key Components

A rotary furnace is a system of a few robust, integrated parts designed for high-temperature, continuous operation.

The Furnace Body and Lining

The outer shell is a durable steel body, built to withstand the mechanical stress of rotation and high external temperatures.

Inside this shell is a critical refractory lining, typically made of specialized bricks or castable cement. This lining serves two purposes: insulating the steel shell from extreme internal heat and resisting chemical corrosion from the molten materials.

The Drive Mechanism

The drive gear is the electromechanical system responsible for rotating the furnace. It is almost always a variable-speed drive, allowing operators to adjust the rotation speed to optimize the tumbling action for different materials. This system also controls the tilting of the furnace.

The Heat Source

The heat is supplied by an internal heat source, most commonly a set of high-output burners located at one or both ends of the furnace. The choice of fuel—gas, oil, or solid—depends on operational costs and availability. This direct heating method is a key reason for the furnace's high efficiency.

Understanding the Trade-offs and Applications

While powerful, a rotary furnace is not a universal solution. It excels in specific scenarios where its unique characteristics provide a distinct advantage.

Primary Use Case: Scrap and Dross Recycling

Rotary furnaces are a mainstay in the secondary metals industry. They are particularly effective for melting aluminum scrap that has a relatively low metal content (often specified as less than 70% aluminum).

They are also the tool of choice for processing dross and slag, which are byproducts of other melting processes, to recover valuable trapped metal.

The Efficiency Advantage

Compared to older designs like reverberatory furnaces, rotary furnaces are significantly more thermally efficient. Their enclosed, rotating design minimizes heat loss through the stack (stack losses), meaning more of the energy from the fuel goes directly into melting the charge.

Material and Process Limitations

The intense tumbling action makes this furnace ideal for bulk solids and scrap. However, it may be too aggressive for delicate materials or applications requiring a very still, controlled atmosphere. The process is optimized for melting and mixing, not for precise chemical refinement that might require a quiescent bath.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your specific processing requirements and materials.

- If your primary focus is recovering metal from low-purity aluminum scrap or dross: The rotary furnace is one of the most efficient and cost-effective tools for this task.

- If your primary focus is ensuring maximum material mixing and a homogenous melt: The constant tumbling action of the rotary furnace is superior to that of any static furnace design.

- If your primary focus is maximizing thermal efficiency for bulk melting: The enclosed design and direct heating methods of a rotary furnace minimize energy waste.

By understanding its core operational principles, you can determine if a rotary furnace is the optimal solution for your material processing challenge.

Summary Table:

| Key Feature | Impact on the Process |

|---|---|

| Rotation & Tumbling | Ensures uniform heat exposure and prevents cold spots, leading to a homogeneous melt. |

| Slight Tilt | Uses gravity to create a continuous flow of material from the charging to the discharge end. |

| Direct Heating & Refractory Lining | Maximizes thermal efficiency by transferring heat directly to the material via a superheated lining. |

| Variable-Speed Drive | Allows operators to optimize the tumbling action for different materials and batch requirements. |

Ready to Optimize Your Metal Recovery Process?

If your goal is to efficiently recover metal from aluminum scrap or dross with superior mixing and thermal efficiency, the rotary furnace is an ideal solution. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions tailored to your unique challenges.

Our product line includes robust Rotary Furnaces, alongside Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. We complement this with strong deep customization capabilities to precisely meet your experimental and production requirements.

Contact our experts today to discuss how a KINTEK rotary furnace can enhance your operation's efficiency and profitability.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules