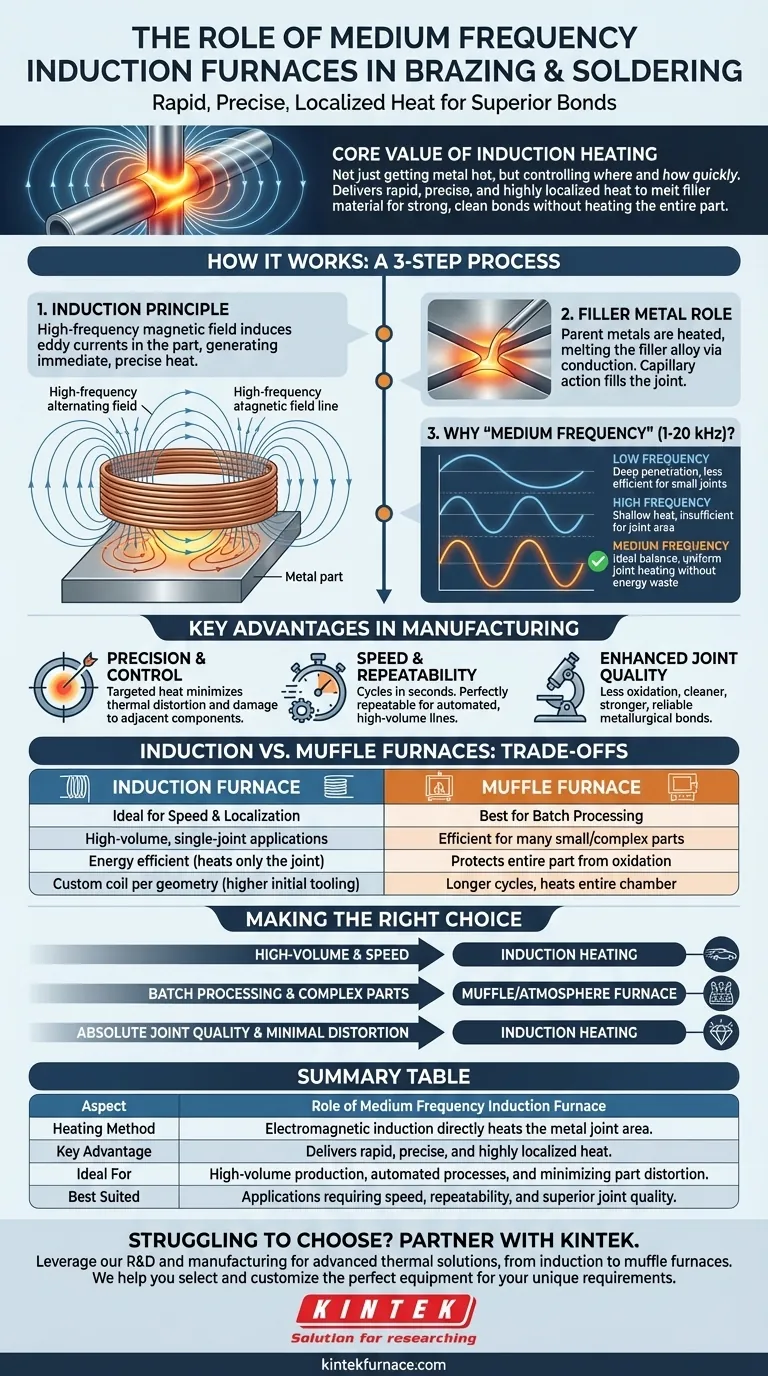

In brazing and soldering, the primary role of a medium frequency induction furnace is to deliver rapid, precise, and highly localized heat. This process uses electromagnetic induction to heat the metal components directly at the joint, which in turn melts the filler material (solder or braze alloy) to create a strong, clean bond without heating the entire part.

The core value of induction heating is not simply getting metal hot, but controlling exactly where and how quickly that heat is applied. This precision gives you superior joint quality, faster production speeds, and higher energy efficiency compared to methods that heat the entire component.

How Induction Brazing and Soldering Works

To understand the role of an induction furnace, you must first understand the fundamental process. It's a method of controlled, contactless heating that excels in repetitive manufacturing environments.

The Principle of Induction Heating

An induction system generates a high-frequency alternating magnetic field around a specially designed copper coil. When a metal part is placed near this coil, the magnetic field induces electrical currents (called eddy currents) within the part itself. The resistance of the metal to these currents generates immediate and precise heat.

The Role of the Filler Metal

In brazing and soldering, the goal is not to melt the base components. Instead, the induction process rapidly heats the parent metals at the joint. This heat is then transferred via conduction to the filler alloy, causing it to melt and flow into the joint through capillary action, forming a permanent bond upon cooling.

Why "Medium Frequency" Is Key

The frequency of the induction system determines how deeply the heat penetrates the material.

- Low frequencies penetrate deeply, which is inefficient for the small-to-medium-sized joints typical in brazing.

- High frequencies create very shallow heat, which may not sufficiently heat the joint area.

Medium frequency (typically 1-20 kHz) offers the ideal balance. It provides enough heat penetration to uniformly heat the joint interface without wasting energy by heating a large, unnecessary volume of the part.

Key Advantages in Manufacturing

The precise nature of induction heating offers significant advantages over traditional flame or furnace heating methods, making it a preferred choice in industries like electronics, plumbing, and automotive manufacturing.

Unmatched Precision and Control

Induction heating is incredibly targeted. Heat is generated only at the joint, minimizing the risk of thermal distortion or damage to adjacent heat-sensitive components. This is critical in electronics or complex assemblies.

Superior Speed and Repeatability

Heating cycles are often completed in a matter of seconds. Once the power level and heating time are set, the process is perfectly repeatable for every part. This makes induction ideal for automated, high-volume production lines where consistency is non-negotiable.

Enhanced Joint Quality

Because the heating is so fast and localized, there is less time for oxidation to form on the component surfaces. This results in cleaner, stronger, and more reliable metallurgical bonds with fewer voids or impurities.

Understanding the Trade-offs: Induction vs. Muffle Furnaces

While powerful, induction heating is not the only method for brazing. Understanding its trade-offs against a common alternative, the muffle furnace, is key to making an informed decision.

Induction Furnaces: Ideal for Speed and Localization

Induction excels at high-volume, single-joint applications. Its primary strengths are speed, repeatability, and energy efficiency, as energy is only used to heat the small area of the joint during the short cycle.

Muffle Furnaces: Best for Batch Processing

A muffle furnace, by contrast, heats the entire component (or a batch of components) inside a chamber. While much slower, this can be more efficient for processing many small parts at once or for complex assemblies where an induction coil cannot be easily positioned. It also protects the entire part from oxidation, not just the joint area.

The Cost and Complexity Factor

An induction setup requires a power supply and a custom-designed coil for each specific joint geometry. This can increase initial tooling costs and complexity. Muffle furnaces are more versatile for varying part shapes but have longer cycle times and consume more energy to heat the entire chamber.

Making the Right Choice for Your Application

Selecting the correct heating technology depends entirely on your production goals, part geometry, and required volume.

- If your primary focus is high-volume production and speed: Induction heating is the definitive choice for its rapid and highly repeatable cycles.

- If your primary focus is processing many small parts at once or joining complex assemblies: A muffle or atmosphere furnace may be more practical and cost-effective.

- If your primary focus is absolute joint quality and minimizing part distortion: Induction's precise, localized heating provides superior control and results.

By understanding the core principles of each method, you can select the technology that delivers the most reliable and cost-effective results for your specific joining process.

Summary Table:

| Aspect | Role of Medium Frequency Induction Furnace |

|---|---|

| Heating Method | Electromagnetic induction directly heats the metal joint area. |

| Key Advantage | Delivers rapid, precise, and highly localized heat. |

| Ideal For | High-volume production, automated processes, and minimizing part distortion. |

| Best Suited | Applications requiring speed, repeatability, and superior joint quality. |

Struggling to choose the right heating technology for your brazing or soldering process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions. Whether your application demands the speed and precision of an induction furnace or the batch-processing capability of a muffle furnace, our team will help you select and customize the perfect equipment.

Our product line includes Tube Furnaces, Vacuum & Atmosphere Furnaces, and more, complemented by strong deep customization capabilities to meet your unique requirements.

Contact our experts today to discuss your project and discover how KINTEK can enhance your manufacturing efficiency and joint quality.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing