In the digital dental workflow, the sintering furnace serves a single, critical function: it transforms a fragile, oversized, and chalk-like milled restoration into its final, dense, and durable state. This controlled heating process, known as sintering, is what gives materials like zirconia their exceptional strength, accurate fit, and desired aesthetic properties. Without this step, modern ceramic restorations would not be clinically viable.

A dental sintering furnace is not merely an oven; it is a precision instrument that governs the final physical properties of a restoration. The quality of the sintering process directly dictates the strength, fit, aesthetics, and long-term clinical success of the final crown, bridge, or veneer.

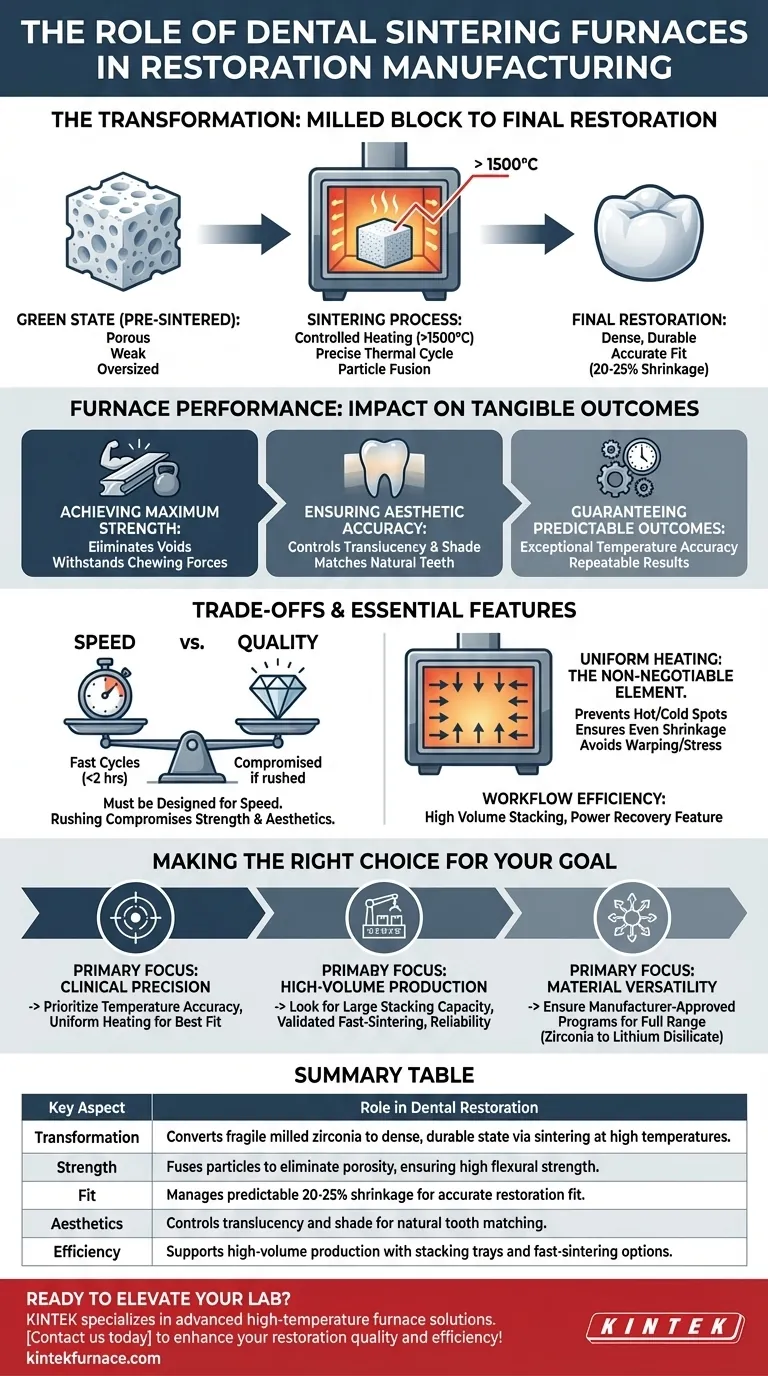

The Transformation from Milled Block to Final Restoration

The journey of a zirconia restoration from a CAD/CAM mill to the patient's mouth involves a crucial metamorphic stage that happens entirely within the furnace. Understanding this transformation is key to appreciating the furnace's role.

From "Green State" to Full Strength

After milling, a zirconia restoration is in its "green state" or pre-sintered phase. It is porous, weak, and significantly larger than its final intended size. The sintering furnace applies a precise thermal cycle, heating the material to temperatures often exceeding 1500°C. This causes the individual ceramic particles to fuse, eliminating porosity and creating a dense, monolithic structure.

The Critical Role of Heat and Time

This is not a simple heating process. The furnace follows a specific program with controlled ramp-up speeds, hold times at peak temperature, and a managed cooling phase. Each stage is vital for achieving the desired material characteristics without introducing thermal stress, which could lead to cracks.

Managing Material Shrinkage for a Precise Fit

Zirconia shrinks significantly during sintering—often by 20-25%. This shrinkage is calculated and accounted for in the initial design phase. The furnace's ability to provide uniform, consistent heating ensures that this shrinkage is predictable and even across the entire restoration, which is fundamental to achieving an accurate final fit.

Key Factors Dictated by Furnace Performance

The quality and features of the furnace directly impact the tangible outcomes of the restoration. Poor furnace control will invariably lead to a poor clinical result.

Achieving Maximum Material Strength

The final flexural strength of the ceramic is determined during sintering. By creating a uniformly dense structure free of internal voids, a high-quality furnace ensures the restoration can withstand the immense chewing forces exerted in the oral environment.

Ensuring Aesthetic Accuracy

The sintering process also influences the final aesthetics, particularly the translucency and shade of the material. Different sintering temperatures and cycles can produce different levels of translucency, allowing technicians to match the restoration to the patient's natural teeth. Inconsistent heating can result in an uneven or incorrect appearance.

Guaranteeing Predictable Outcomes

Modern furnaces provide exceptional temperature accuracy and control. This reliability ensures that the results of a sintering cycle are predictable and repeatable, batch after batch. This consistency is the foundation of an efficient and high-quality laboratory workflow.

Understanding the Trade-offs and Essential Features

While all sintering furnaces perform the same basic function, their specific features create important trade-offs between speed, quality, and throughput.

Speed vs. Quality in Sintering Cycles

Many modern furnaces offer "fast" or "speed" sintering cycles that can reduce the process from many hours to under two hours. While this dramatically improves turnaround time, it must be done with a furnace designed for it. Rushing the process with an inadequate machine can compromise strength and aesthetics.

Uniform Heating: The Non-Negotiable Element

The most critical feature of any furnace is its ability to heat the entire chamber uniformly. Advanced heating elements and chamber design prevent "hot spots" or "cold spots" that would cause uneven shrinkage, leading to warped margins, poor fit, or internal stresses that doom the restoration to premature failure.

Workflow Efficiency and Reliability

Features like the ability to stack multiple trays allow a lab to process a high volume of restorations (up to 150 units in some models) in a single cycle. Furthermore, a power interruption recovery feature is invaluable, as it can save an entire batch of work from being ruined during an unexpected power outage.

Making the Right Choice for Your Goal

The ideal furnace depends entirely on the specific goals of your dental lab or practice. Use these principles to guide your evaluation.

- If your primary focus is ultimate clinical precision: Prioritize furnaces renowned for their temperature accuracy and uniform heating to guarantee the best possible fit and material integrity.

- If your primary focus is high-volume production: Look for furnaces with large stacking capacity, validated fast-sintering programs, and reliability features like power interruption recovery.

- If your primary focus is material versatility: Ensure the furnace has manufacturer-approved programs for the full range of materials you plan to use, from high-strength zirconia to aesthetic lithium disilicate.

Mastering the sintering process is fundamental to delivering a restoration that is not just made, but expertly crafted.

Summary Table:

| Key Aspect | Role in Dental Restoration |

|---|---|

| Transformation | Converts fragile milled zirconia to dense, durable state via sintering at high temperatures (e.g., >1500°C). |

| Strength | Fuses particles to eliminate porosity, ensuring high flexural strength for chewing forces. |

| Fit | Manages predictable 20-25% shrinkage for accurate restoration fit through uniform heating. |

| Aesthetics | Controls translucency and shade for natural tooth matching, dependent on sintering cycles. |

| Efficiency | Supports high-volume production with features like stacking trays and fast-sintering options. |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Vacuum & Atmosphere Furnaces, with strong deep customization to meet your unique needs—whether you prioritize clinical precision, high-volume production, or material versatility. Contact us today to discuss how our furnaces can enhance your restoration quality and workflow efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity