At its core, the purpose of a muffle furnace in incineration is to completely and cleanly reduce a small sample to its inorganic ash content. This process, known as ashing, is performed in a highly controlled and non-contaminating environment, ensuring the resulting ash is pure and suitable for precise quantitative analysis.

The key isn't simply to burn the sample, but to do so with extreme precision. A muffle furnace isolates the sample from the heat source and any contaminants, guaranteeing that the final ash is a true representation of the original material's inorganic components.

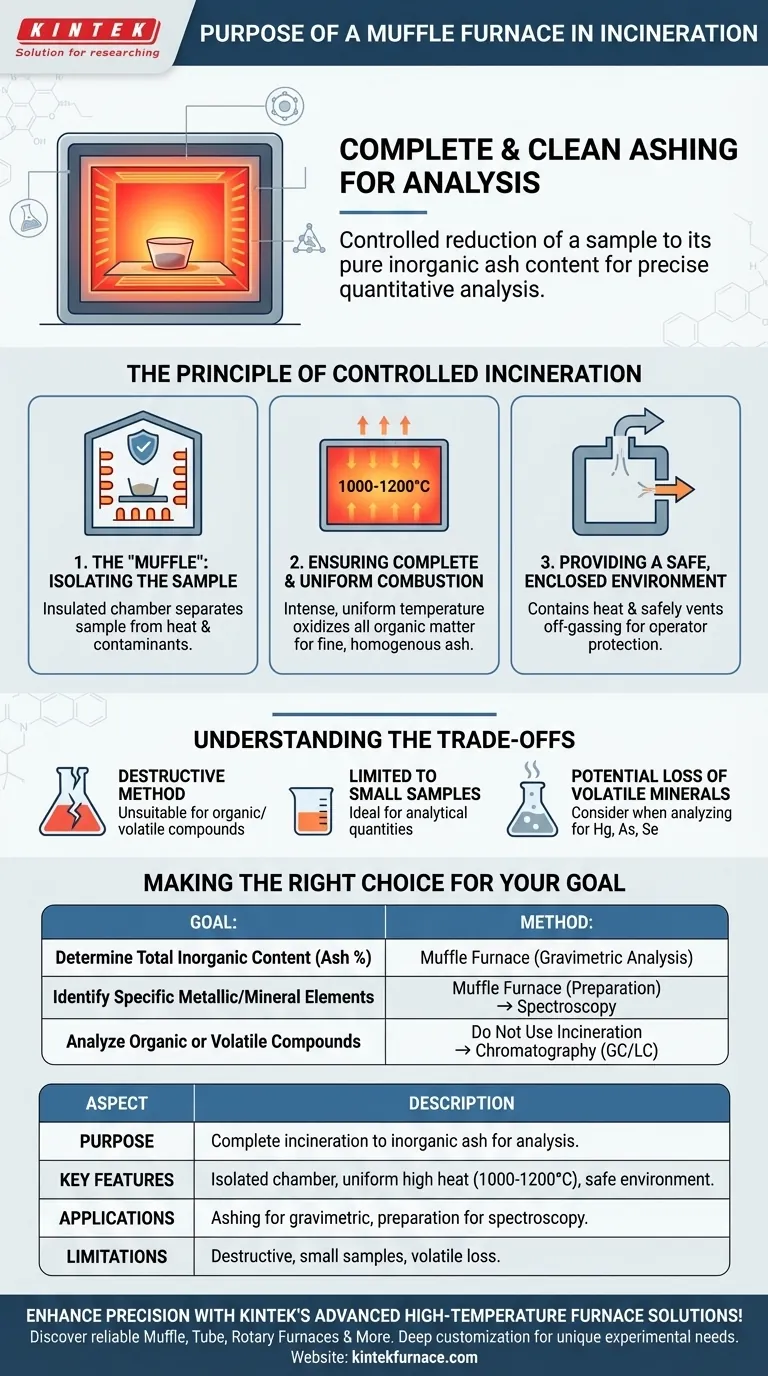

The Principle of Controlled Incineration

Using a simple flame or oven for incineration introduces variables and contaminants that make accurate analysis impossible. A muffle furnace is specifically engineered to eliminate these problems through three key principles.

The "Muffle": Isolating the Sample

The term "muffle" refers to the furnace's core design feature: an insulated chamber that separates the sample from the heating elements.

Historically, this was critical for isolating the sample from the fuel and combustion byproducts of coal or gas burners. While modern furnaces use clean electric heating elements, the principle of separation still prevents any direct contamination of the sample.

Ensuring Complete and Uniform Combustion

A muffle furnace provides extremely high and evenly distributed heat, often reaching 1000-1200°C.

This intense, uniform temperature ensures that all organic matter in the sample is completely oxidized and burned away. The result is a fine, homogenous ash, which is essential for obtaining accurate and repeatable measurements.

Providing a Safe, Enclosed Environment

Incinerating materials can release fumes and involves dangerously high temperatures.

The insulated, enclosed chamber of a muffle furnace contains the heat and safely vents any off-gassing. This protects the lab environment and the operator from exposure, making it a standard piece of safety equipment for high-temperature thermal processing.

Understanding the Trade-offs

While invaluable for ashing, a muffle furnace is a specialized tool with clear limitations. Understanding these is crucial for proper application.

It Is a Destructive Method

The entire purpose of incineration is to destroy the organic portion of the sample. If you need to analyze organic or volatile compounds, this method is entirely unsuitable.

Limited to Small Sample Sizes

Muffle furnaces are designed for analytical work, not bulk processing. They are ideal for handling the small, measured quantities of material required for quality control or chemical analysis, typically just a few grams.

Potential Loss of Volatile Minerals

While the goal is to retain inorganic ash, certain mineral compounds can become volatile and be lost at the very high temperatures used. This must be considered when analyzing for elements like mercury, arsenic, or selenium, which may require modified procedures or different analytical methods.

Making the Right Choice for Your Goal

Select your analytical method based on what part of the sample you need to measure.

- If your primary focus is determining total inorganic content (ash %): The muffle furnace is the definitive tool for this type of gravimetric analysis.

- If your primary focus is identifying specific metallic or mineral elements: Use the muffle furnace to prepare the ash, then employ a secondary method like spectroscopy to analyze the ash itself.

- If your primary focus is analyzing organic or volatile compounds: Do not use incineration; choose a method like chromatography (GC/LC) or direct thermal desorption instead.

Ultimately, a muffle furnace provides the control necessary to transform a complex sample into a simple form for accurate inorganic analysis.

Summary Table:

| Aspect | Description |

|---|---|

| Purpose | Complete incineration of samples to inorganic ash for quantitative analysis. |

| Key Features | Isolated chamber, uniform high heat (1000-1200°C), safe enclosed environment. |

| Applications | Ashing for gravimetric analysis, preparation for spectroscopy in labs. |

| Limitations | Destructive method, small sample sizes, potential loss of volatile minerals. |

Enhance your laboratory's precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for accurate ashing and analysis. Contact us today to discuss how we can optimize your incineration processes and deliver superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis