In short, the silica layer on a Molybdenum Disilicide (MoSi2) heating element serves as a critical protective barrier. This thin, glass-like layer forms on the element's surface when it is heated in the presence of oxygen. Its sole purpose is to seal the core material off from the surrounding atmosphere, preventing a destructive internal oxidation process that would otherwise cause the element to fail rapidly at high temperatures.

The self-healing silica layer is not just a simple coating; it is the key mechanism that allows MoSi2 elements to achieve exceptionally high operating temperatures and long lifespans. Understanding this layer is fundamental to understanding the element's performance.

The Fundamental Challenge: Oxidation at Extreme Temperatures

To appreciate the role of the silica layer, we must first understand the hostile environment in which these elements operate. They are designed to function at temperatures where most metals would quickly degrade.

How Heating Elements Work

At its core, a MoSi2 element functions through Joule heating. As electrical current is passed through the element, it encounters electrical resistance. This resistance converts the electrical energy into thermal energy, causing the element to become extremely hot.

The Inevitable Threat of Oxygen

The primary material, molybdenum disilicide (MoSi2), is an excellent choice for high-temperature applications. However, at the extreme temperatures required for industrial furnaces and lab equipment, atmospheric oxygen becomes highly reactive and would aggressively attack and destroy the molybdenum component of the element's core.

The Solution: A Self-Generating Shield

The genius of MoSi2 lies in its silicon (Si) content. During an initial firing process, or during its first heat-up, the silicon on the surface of the element intentionally reacts with oxygen. This reaction forms a thin, non-porous, and highly stable layer of silicon dioxide (SiO2)—more commonly known as silica or quartz glass.

This silica layer is passive and chemically stable, acting as a perfect gas barrier. It prevents oxygen from penetrating further into the element and reaching the vulnerable molybdenum core.

How the Silica Layer Enables Superior Performance

The formation of this protective layer is directly responsible for the key advantages that make MoSi2 elements a preferred choice for high-temperature applications.

Achieving Unmatched Operating Temperatures

The silica layer is exceptionally stable at very high temperatures. This protective shield is what allows MoSi2 elements to operate consistently at temperatures up to 1850°C (3360°F), far beyond the limits of many other metallic heating elements.

Ensuring a "Self-Healing" Lifespan

Perhaps the most critical property of this layer is its ability to self-heal. If a small crack or spall appears on the surface due to thermal shock or mechanical stress, the newly exposed MoSi2 core will immediately react with oxygen in the atmosphere. This re-forms the silica layer, effectively "healing" the breach and continuing to protect the element. This process is the reason MoSi2 elements have the longest inherent lifespan of all electric heating elements.

Maintaining Stable Electrical Resistance

Because the silica layer effectively prevents the core material from degrading over time, the element's fundamental electrical properties remain remarkably stable. This stable resistance means that performance is predictable and allows for new elements to be connected in series with older ones without causing system imbalances.

Understanding the Trade-offs and Limitations

While highly effective, the silica layer's protective capability is not absolute and is subject to specific operating conditions.

Vulnerability to "Pest" Oxidation

MoSi2 elements are optimized for high-temperature operation. Paradoxically, prolonged operation in a lower temperature range—typically 400°C to 700°C (750°F to 1300°F)—can lead to a destructive phenomenon known as pest oxidation. In this range, the material rapidly disintegrates into a powder. For this reason, it is critical to heat elements rapidly through this temperature zone.

Chemical Attack

The protective silica layer can be compromised by certain furnace atmospheres. Chemical agents like fluorine, sulfur, and hydrogen can attack the SiO2, degrading its integrity and exposing the core to oxidation. It is essential to ensure the process atmosphere is compatible with a silica-based protective layer.

Making the Right Choice for Your Goal

Understanding the function of the silica layer allows you to operate and maintain your heating equipment more effectively.

- If your primary focus is maximizing element lifespan: Rapidly heat the elements through the 400-700°C "pest" range and ensure a clean, oxygen-bearing atmosphere to support the self-healing process.

- If your primary focus is process stability at high temperatures: Rely on the stability of the silica layer, but be mindful of any chemical contaminants in your furnace that could attack it and lead to premature failure.

- If you are troubleshooting element failure: A compromised silica layer, visible as flaking or discoloration, is a primary indicator that the element's failure is likely due to chemical attack or operation in the pest temperature range.

Ultimately, viewing the silica layer as a dynamic, regenerative shield is the key to unlocking the full performance and longevity of MoSi2 heating systems.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Protects MoSi2 core from oxidation by forming a barrier |

| Formation | Self-generates from silicon reacting with oxygen at high temperatures |

| Key Benefits | Enables operation up to 1850°C, self-healing capability, stable electrical resistance |

| Limitations | Vulnerable to pest oxidation at 400-700°C and chemical attack (e.g., fluorine, sulfur) |

Unlock the full potential of your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable heating elements and systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs, enhancing performance and longevity. Contact us today to discuss how we can support your goals!

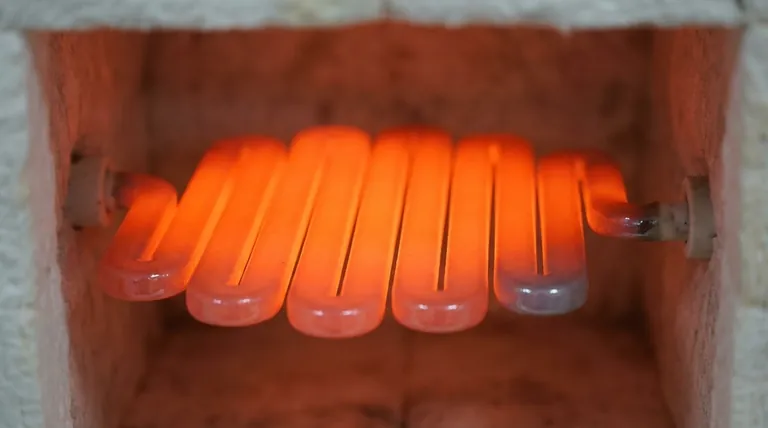

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions