At their core, dental ceramic furnaces are highly specialized ovens used to fire materials like porcelain and zirconia. This firing process is what transforms these materials from a fragile, chalk-like state into strong, durable, and aesthetically pleasing dental restorations such as crowns, bridges, veneers, and inlays.

A dental furnace isn't just about heat; it's about transformation. It uses precisely controlled heating cycles to convert weak, pre-processed ceramic materials into biocompatible restorations with the strength to withstand chewing and the lifelike appearance to blend seamlessly with natural teeth.

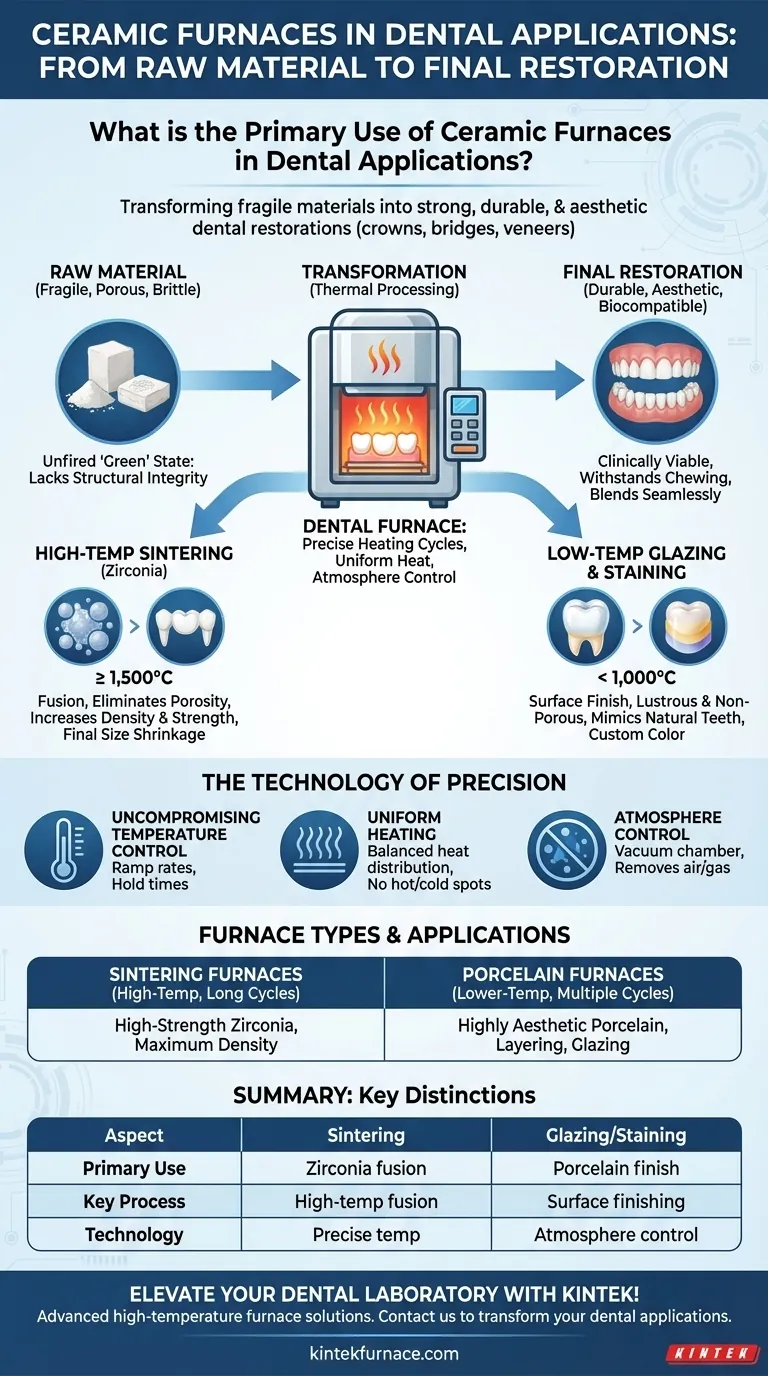

From Raw Material to Final Restoration

A furnace is the critical link between a digitally designed or manually shaped restoration and a clinically viable product. Without this thermal processing step, modern dental ceramics would be functionally useless.

The Fundamental Problem: Why Firing is Necessary

Raw dental ceramic, whether it's a milled zirconia block or pressed porcelain, lacks the structural integrity for use in the mouth. In this "green" or unfired state, the material is porous and brittle, unable to withstand the functional forces generated during chewing.

The furnace solves this by fundamentally changing the material's microstructure, converting it into a dense and hardened final form.

The Key Processes: Sintering and Glazing

A furnace performs two primary types of thermal processing, depending on the material and the desired outcome.

Sintering is a high-temperature process used primarily for zirconia. During sintering, the furnace heats a milled restoration to temperatures often exceeding 1,500°C, causing the individual ceramic particles to fuse. This eliminates porosity, shrinks the restoration to its final size, and dramatically increases its density and strength.

Glazing and Staining are lower-temperature firing cycles used to finalize the restoration's appearance. A thin layer of glass (glaze) is applied and fired to create a smooth, lustrous, and non-porous surface. Colorants (stains) can also be fired onto the surface to mimic the subtle characteristics of natural teeth.

The Technology That Enables Precision

The success of a dental restoration is directly tied to the accuracy of the firing cycle. Modern dental furnaces are engineered for uncompromising precision to ensure predictable and repeatable results.

Uncompromising Temperature Control

Dental furnaces do not simply get hot; they follow exact firing schedules with precise temperature ramp rates, hold times (known as "soaking"), and controlled cooling. Different materials, such as zirconia and lithium disilicate, have unique thermal requirements, and even a minor deviation can compromise the restoration's strength or aesthetics.

Uniform Heating for Consistent Results

The furnace's heating chamber is designed to eliminate hot and cold spots, ensuring the entire restoration is heated uniformly. Uneven heating can create internal stresses, leading to cracks or fractures either immediately after firing or, worse, after it has been placed in the patient's mouth.

Atmosphere Control

Many firing cycles, especially for porcelain, are performed under a vacuum. Removing air from the chamber during the heating phase prevents gas bubbles from being trapped within the ceramic, which increases the material's translucency and strength.

Understanding the Key Distinctions

Not all dental furnaces are the same. The type of furnace a dental laboratory uses is dictated entirely by the materials they work with.

Sintering Furnaces vs. Porcelain Furnaces

These represent the two main categories. Sintering furnaces are built to reach the extremely high temperatures required to process zirconia over long cycles. Porcelain furnaces operate at lower temperatures and are designed for the shorter, more numerous cycles needed for layering, staining, and glazing porcelain.

A Dedicated Tool for Each Material

A single furnace is rarely a "one-size-fits-all" solution. A high-production dental lab will typically operate multiple types of furnaces to efficiently handle the full range of modern materials, from high-strength zirconia for posterior bridges to highly aesthetic feldspathic porcelain for anterior veneers.

Applying This to Your Dental Goal

The specific furnace process used is determined by the clinical demands of the restoration.

- If your primary focus is a high-strength monolithic zirconia crown: The restoration will undergo a long, high-temperature cycle in a sintering furnace to achieve maximum density and fracture resistance.

- If your primary focus is a highly aesthetic layered porcelain veneer: The restoration will undergo multiple, shorter, lower-temperature cycles in a porcelain furnace to build up layers of color, translucency, and a final glaze.

- If your primary focus is adding custom color to a milled crown: The restoration will be placed in a furnace for a brief stain-and-glaze cycle to apply surface characteristics and seal the material.

Ultimately, mastering the furnace is mastering the art and science of modern dental restorations.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | Firing ceramic materials like porcelain and zirconia to create dental restorations (e.g., crowns, bridges, veneers). |

| Key Processes | Sintering (for zirconia, high-temperature fusion) and glazing/staining (for porcelain, surface finishing). |

| Technology Features | Precise temperature control, uniform heating, and atmosphere control (e.g., vacuum) for consistent, high-quality results. |

| Furnace Types | Sintering furnaces (high-temperature for zirconia) and porcelain furnaces (lower-temperature for layering and glazing). |

Elevate your dental laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization ensures precise alignment with your unique experimental needs, enhancing efficiency and restoration quality. Contact us today to discuss how our furnaces can transform your dental applications and drive success!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- What is the main purpose of a sintering furnace in dentistry? Transform Zirconia into Strong Dental Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations