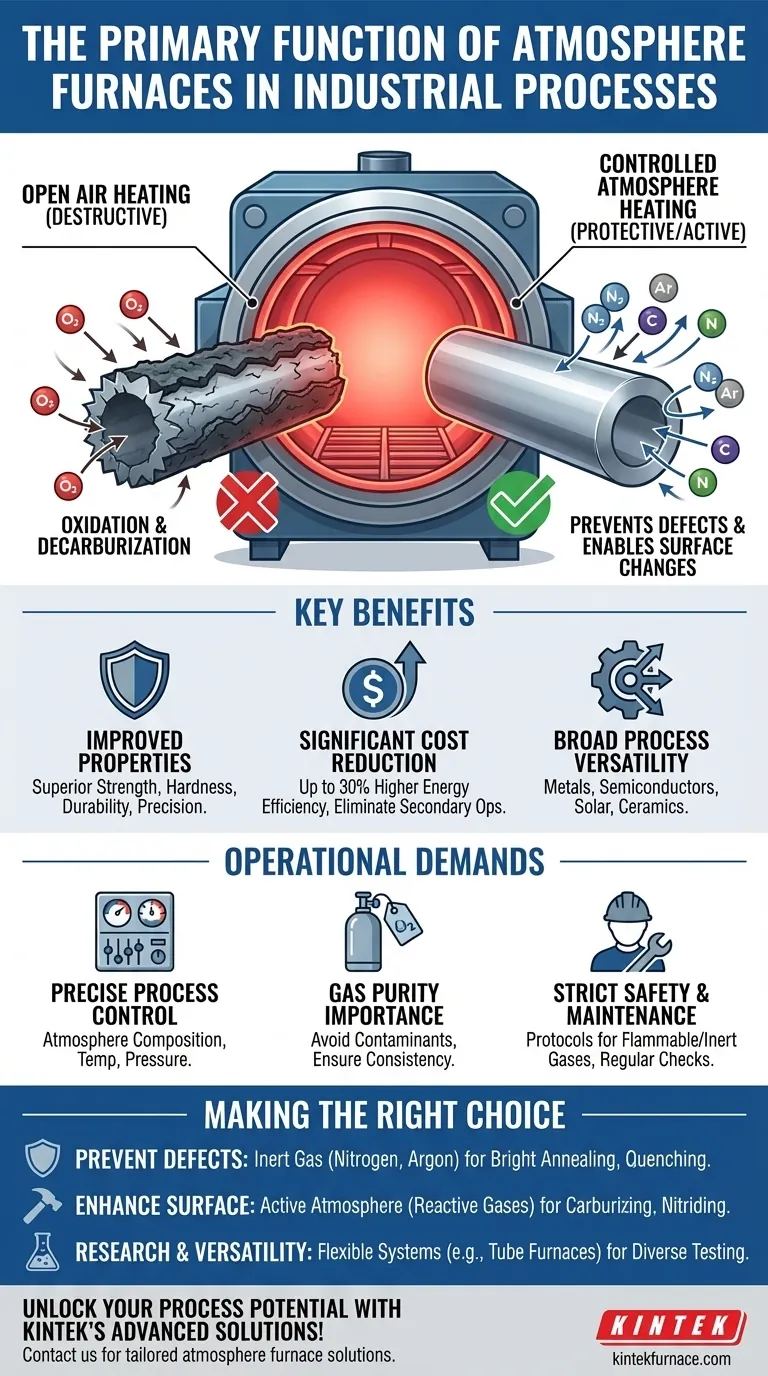

At its core, an atmosphere furnace is a specialized high-temperature chamber that allows for the precise control of the gaseous environment surrounding a material during heat treatment. Its primary function is to heat a material while simultaneously protecting it from unwanted chemical reactions—like oxidation and rust—or intentionally introducing specific reactions to enhance the material's properties.

The crucial insight is that for many advanced materials, the act of heating is inseparable from the chemical environment it occurs in. An atmosphere furnace isn't just about applying heat; it's about using a controlled atmosphere to dictate the chemical outcome of the heating process, preventing damage and enabling specific transformations.

The Core Problem: Why Heat Treatment Needs a Controlled Atmosphere

Heating materials, especially metals, in open air can be destructive. The high temperatures act as a catalyst for rapid, unwanted chemical reactions with the ambient atmosphere.

Preventing Destructive Reactions

At high temperatures, the oxygen in the air aggressively reacts with many materials. In steels, this leads to two common problems:

- Oxidation: The formation of a rough, dark scale on the metal's surface, which compromises its finish and dimensional accuracy.

- Decarburization: The loss of carbon content from the surface of steel, which makes it softer and weaker.

An atmosphere furnace prevents this by replacing the air with a controlled mixture of gases that do not react negatively with the material.

Enabling Specific Chemical Changes

Beyond mere protection, these furnaces can use an active atmosphere to intentionally change a material's surface chemistry.

By introducing specific gases at high temperatures, processes like gas carburizing (adding carbon to the surface) or carbonitriding (adding carbon and nitrogen) can be performed. This creates a hard, wear-resistant outer layer on a component while keeping the inner core tough and ductile.

Key Benefits of Using an Atmosphere Furnace

Controlling the atmosphere unlocks significant improvements in both the final product and the manufacturing process itself.

Improved Material Properties

By preventing defects like oxidation and enabling surface enhancements like carburizing, the final product exhibits superior strength, hardness, and durability. This precision ensures that materials meet strict engineering specifications consistently.

Significant Cost Reduction

Atmosphere furnaces offer a direct path to cost savings. By optimizing heat retention and distribution, they can achieve up to 30% higher energy efficiency compared to conventional open-air furnaces.

Furthermore, by eliminating surface defects, they reduce the need for costly and time-consuming secondary operations like cleaning, grinding, or machining away a damaged layer.

Broad Process Versatility

The ability to create different atmospheres makes these furnaces incredibly versatile. They are critical tools in a wide range of industries, including:

- Metal and material processing

- Semiconductor and electronic component manufacturing

- Solar cell and new energy R&D

- Ceramics and glass production

Understanding the Operational Demands

While powerful, an atmosphere furnace is a precision instrument that demands careful operation to deliver quality results and ensure safety.

The Need for Precise Process Control

These are not "set and forget" devices. Achieving the desired outcome requires continuous monitoring and management of the furnace's internal conditions. This includes maintaining the correct atmospheric composition, temperature uniformity, and internal pressure.

The Importance of Gas Purity

The success of the heat treatment process is directly tied to the purity of the gases used to create the atmosphere. Impurities in the gas supply can introduce contaminants, leading to failed batches and inconsistent material properties.

Strict Safety and Maintenance Protocols

Operating at high temperatures with controlled atmospheres—which may involve flammable or inert gases—requires strict safety protocols to protect operators and equipment. Regular maintenance is essential to ensure seals are tight, sensors are accurate, and safety systems are functional.

Making the Right Choice for Your Process

Your specific goal will determine the type of atmosphere and operational focus you need.

- If your primary focus is preventing defects: Use an inert gas like nitrogen or argon to create a protective, non-reactive atmosphere for processes like bright annealing or quenching.

- If your primary focus is enhancing surface properties: You will need an active atmosphere with a precise mixture of reactive gases for processes like carburizing or nitriding.

- If your primary focus is research and versatility: Look for a furnace system, such as a tube furnace, that offers flexible configurations for testing various materials, temperatures, and gas compositions.

Ultimately, mastering the furnace's atmosphere gives you direct control over your material's final characteristics and quality.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Heat materials in a controlled gaseous environment to prevent unwanted reactions or enable specific chemical changes. |

| Key Benefits | Improved material properties (e.g., strength, hardness), up to 30% higher energy efficiency, cost reduction by eliminating defects, and process versatility across industries. |

| Common Applications | Metal processing, semiconductor manufacturing, solar cell R&D, ceramics and glass production. |

| Operational Considerations | Requires precise control of atmosphere composition, temperature, and pressure; gas purity is critical; strict safety and maintenance protocols are necessary. |

Unlock the full potential of your industrial processes with KINTEK's advanced atmosphere furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and material quality. Contact us today to discuss how our tailored solutions can benefit your operations!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening