At its core, the primary function of a dental furnace is to use precisely controlled high temperatures to transform ceramic materials into durable, aesthetic, and functional dental restorations. This process, known as firing or sintering, is what gives crowns, bridges, and veneers their final strength, color, and shape.

The furnace is not merely an oven; it is a precision instrument that engineers the final physical and aesthetic properties of a dental ceramic, turning a raw or partially processed material into a final clinical restoration.

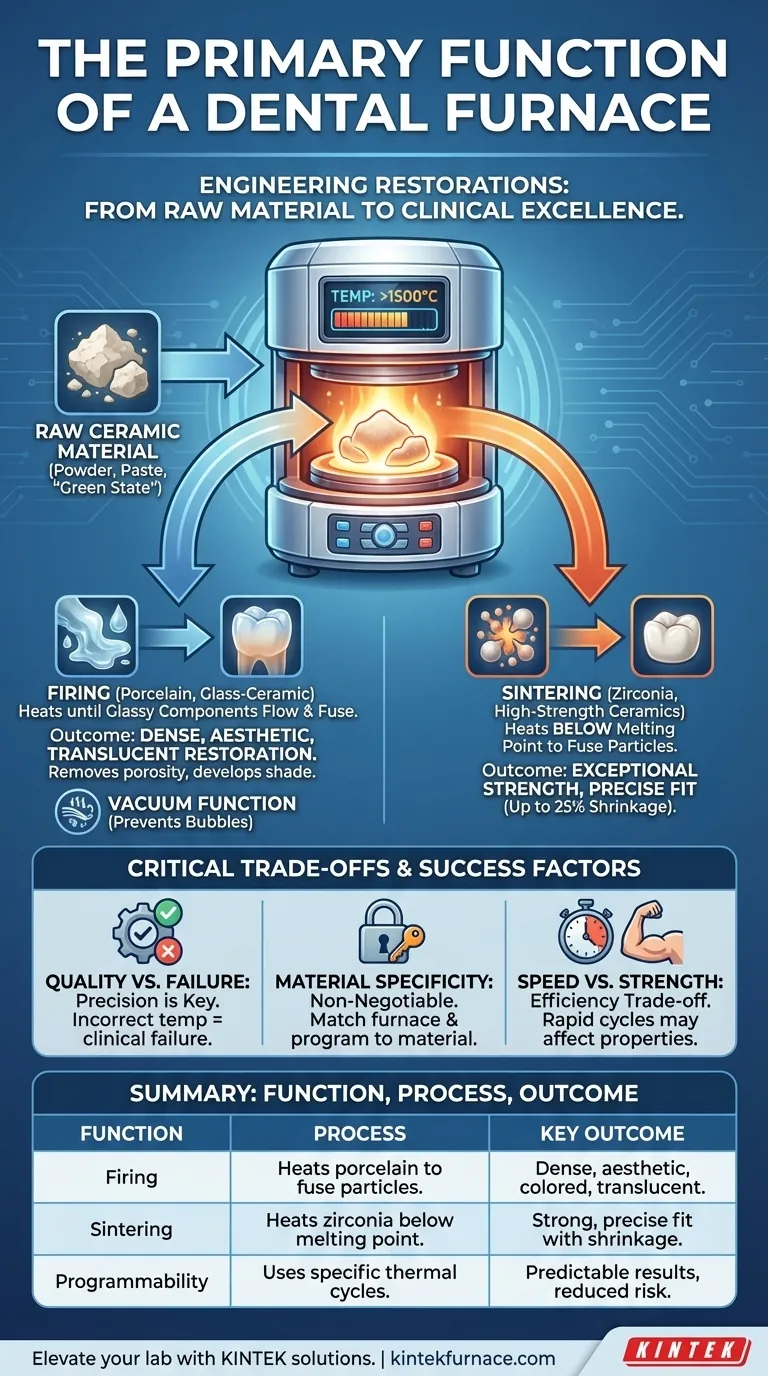

The Core Process: Transforming Ceramic into Restorations

A dental furnace is the critical link between a raw ceramic material and the final restoration that is placed in a patient's mouth. Its function goes far beyond simple heating.

From Raw Material to Final Form

Ceramic restorations begin as either a powder, a paste, or a partially sintered block (known as the "green state" or "chalky state"). These initial forms lack the necessary strength and aesthetic properties for clinical use.

The furnace applies a specific thermal cycle—a pre-programmed sequence of heating, holding, and cooling—to fundamentally change the material's microstructure.

The Role of Firing

Firing is the process typically used for porcelain and glass-ceramic materials. It involves heating the material until its glassy components flow and fuse together, binding the crystalline particles.

This process removes porosity, making the material dense and strong. It is also where the material develops its final shade and translucency, critical for an aesthetic match.

The Role of Sintering

Sintering is used for high-strength ceramics like zirconia. The material is heated to a very high temperature, but crucially, below its melting point.

At this temperature, the individual ceramic particles fuse at their contact points. The restoration densifies and shrinks significantly—up to 25%—achieving its exceptional final strength and precise fit.

Common Furnace Types and Their Functions

Different ceramic materials require different thermal processes, which is why specialized furnaces exist. Each is designed to execute a specific task with maximum precision.

Porcelain Furnaces

These are designed for firing layered porcelains. They often include a vacuum function, which pulls air out of the porcelain during heating. This prevents bubbles and creates a denser, more translucent, and aesthetically superior restoration.

Sintering Furnaces

These furnaces are built to reach the extreme temperatures (often 1500°C or higher) required to sinter materials like zirconia. Their primary function is to transform the soft, milled zirconia block into a restoration with one of the highest flexural strengths in dentistry.

Programmability and Control

Modern dental furnaces are highly programmable. Technicians input specific firing or sintering schedules based on the ceramic manufacturer's instructions. This precise control over heating rates, hold times, and cooling is essential for achieving predictable and successful results.

Understanding the Critical Trade-offs

Investing in a high-quality furnace is not a matter of preference; it directly impacts the quality of patient care and the efficiency of the laboratory.

Quality vs. Failure

An inaccurate or inconsistent furnace will produce weak, poorly fitting, or aesthetically compromised restorations. An incorrect temperature, even by a few degrees, can ruin the material's properties, leading to clinical failure and costly remakes.

Material Specificity is Non-Negotiable

You cannot sinter zirconia in a standard porcelain furnace, as it cannot reach the required temperatures. Likewise, using an incorrect program for a specific ceramic will result in a failed restoration. The furnace and the program must be perfectly matched to the material.

Speed vs. Strength

Some modern sintering furnaces offer "speed" cycles that drastically reduce processing time. While this improves efficiency, there is a trade-off. These rapid cycles may not always achieve the same level of strength or translucency as a standard, longer cycle.

Making the Right Choice for Your Goal

Your choice and use of a dental furnace must align directly with the clinical and business objectives of your practice or laboratory.

- If your primary focus is high-end aesthetics: A top-tier porcelain furnace with excellent vacuum control is essential for creating lifelike anterior restorations.

- If your primary focus is strength and durability: A reliable zirconia sintering furnace that can hold precise high temperatures consistently is the cornerstone of producing robust posterior crowns and bridges.

- If your primary focus is laboratory efficiency: Investing in programmable, versatile furnaces that can handle multiple materials and potentially offer validated speed-sintering cycles is key to managing workflow.

Ultimately, the dental furnace is the tool that brings the science of dental materials to life, enabling the creation of long-lasting and beautiful restorations.

Summary Table:

| Function | Process | Key Outcome |

|---|---|---|

| Firing | Heats porcelain/glass-ceramics to fuse particles | Dense, aesthetic restorations with color and translucency |

| Sintering | Heats high-strength ceramics like zirconia below melting point | Strong, precise-fitting restorations with up to 25% shrinkage |

| Programmability | Uses specific thermal cycles for heating, holding, cooling | Predictable results and reduced risk of failure |

Elevate your dental lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for precision. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is enhanced by deep customization to meet your unique needs for aesthetic, strong, or efficient restorations. Contact us today to discuss how our furnaces can transform your ceramic processing and boost your success!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations