At its core, the main purpose of a muffle furnace is to heat materials to very high temperatures within an exceptionally clean and controlled environment. Unlike other ovens, its defining feature is an internal chamber, or "muffle," that isolates the material being heated from the heating elements, ensuring the sample is not contaminated by any byproducts of the heating process itself.

The true value of a muffle furnace isn't just its ability to generate high heat. Its primary purpose is to provide heating without contamination, which is critical for scientific analyses and advanced material processing where purity and accuracy are non-negotiable.

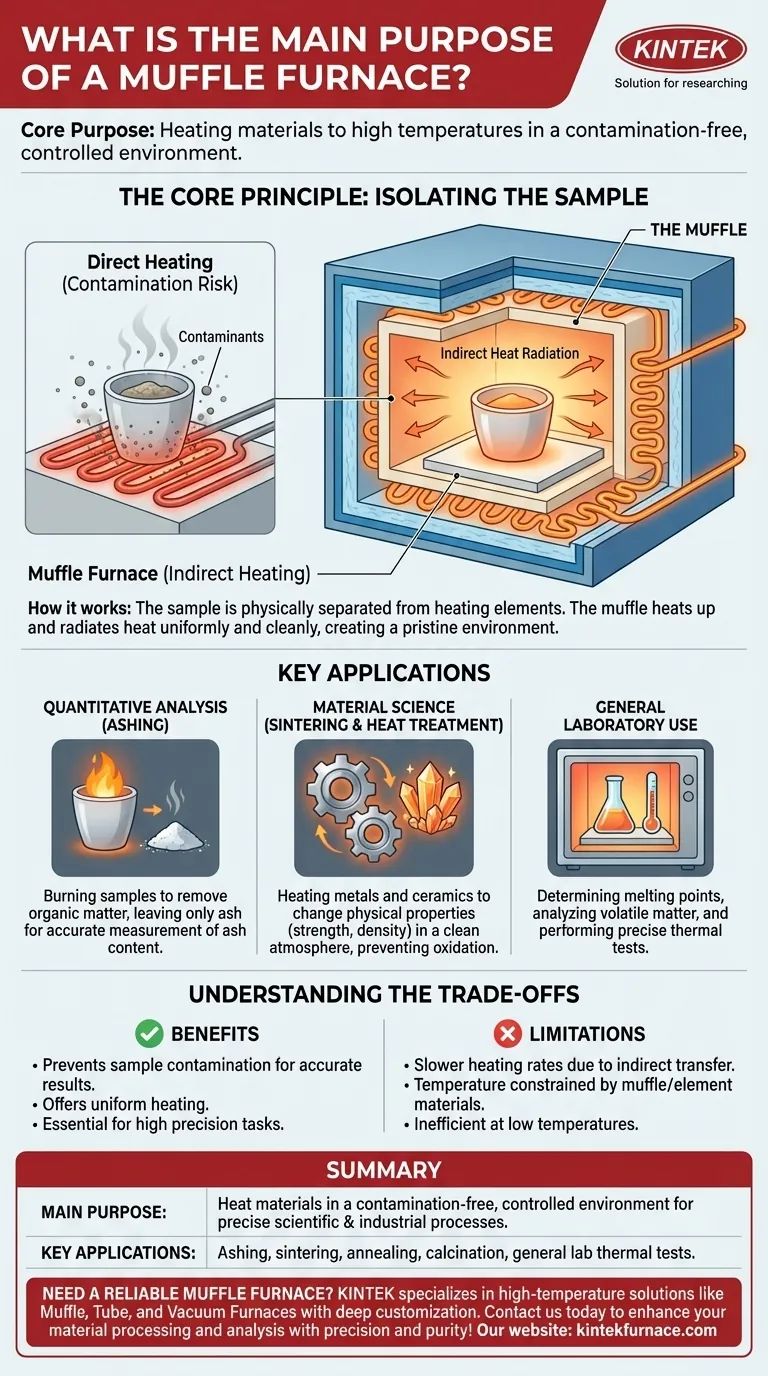

The Core Principle: Isolating the Sample

The design of a muffle furnace is deceptively simple but solves a fundamental problem in high-temperature work. It operates on the principle of indirect heating.

What is a "Muffle"?

The muffle is a box-like, insulated chamber, typically made of a high-temperature ceramic. It sits inside the furnace's main insulated casing.

Heating elements, such as coils of Kanthal or nickel-chromium wire, are wrapped around the outside of the muffle. This is the critical design choice.

The Problem of Contamination

In many scientific and industrial processes, direct contact with the heat source is problematic.

In fuel-fired furnaces, combustion byproducts (like soot or gases) can react with the sample, altering its chemical composition and invalidating results. Even in electric furnaces, the heating elements can degrade over time and shed microscopic particles onto the sample.

How the Muffle Prevents Contamination

By placing the sample inside the muffle, it is physically separated from the heating elements. The elements heat the muffle chamber, which then radiates heat uniformly and cleanly onto the sample inside.

This creates a pristine heating environment free from outside variables, ensuring that any changes to the sample are a result of the heat alone.

Key Applications Driven by Precision

The need for a contamination-free environment makes the muffle furnace indispensable in several fields.

Quantitative Analysis (Ashing)

One of the most common uses is ashing. This process involves burning a sample at high temperatures to completely remove all organic matter, leaving only the inorganic, non-combustible ash.

This is done to determine the ash content of a material, such as in food science or quality control. Using a muffle furnace is essential because any contamination would add mass to the final ash, skewing the measurement.

Material Science (Sintering and Heat Treatment)

In material science, a muffle furnace is used for processes like sintering, annealing, and calcination. These involve heating metals, ceramics, or powders to change their physical properties like strength or density.

A controlled, clean atmosphere is vital to prevent unwanted chemical reactions (like oxidation) on the material's surface, ensuring the final product has the desired characteristics.

General Laboratory Use

Muffle furnaces are also workhorses in research and testing labs for determining the melting points of substances, analyzing volatile matter, and performing various other thermal tests where repeatable and accurate results are paramount.

Understanding the Trade-offs

While powerful, the muffle furnace design has specific limitations you must consider.

Slower Heating Rates

Because the heat is transferred indirectly—from the elements to the muffle, and then from the muffle to the sample—heating can be slower compared to a direct-fired furnace. The muffle itself has thermal mass that needs to be heated up.

Temperature Constraints

The maximum operating temperature of the furnace is ultimately limited by the materials used to construct the muffle and the heating elements.

Inefficiency at Low Temperatures

These furnaces are designed and insulated for high-temperature work. They are generally not suitable or energy-efficient for low-temperature applications that could be handled by a standard laboratory oven.

Making the Right Choice for Your Goal

Selecting the correct heating instrument depends entirely on the level of precision your task requires.

- If your primary focus is quantitative analysis (ashing, elemental analysis): A muffle furnace is mandatory to prevent contamination and ensure the accuracy of your results.

- If your primary focus is creating materials with specific properties (sintering, annealing): A muffle furnace provides the clean and predictable atmosphere needed for reliable outcomes.

- If your primary focus is simply bulk heating where minor contamination is not a concern: A simpler, direct-heat furnace may be a more cost-effective and faster option.

Ultimately, a muffle furnace is the right tool when the integrity of your sample cannot be compromised.

Summary Table:

| Feature | Description |

|---|---|

| Main Purpose | Heat materials in a contamination-free, controlled environment for precise scientific and industrial processes. |

| Key Applications | Ashing, sintering, annealing, calcination, and general laboratory thermal tests. |

| Benefits | Prevents sample contamination, ensures accurate results, and offers uniform heating. |

| Limitations | Slower heating rates, temperature constraints, and inefficiency at low temperatures. |

Need a reliable muffle furnace for contamination-free heating? KINTEK specializes in high-temperature solutions like Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique lab needs. Contact us today to enhance your material processing and analysis with precision and purity!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?