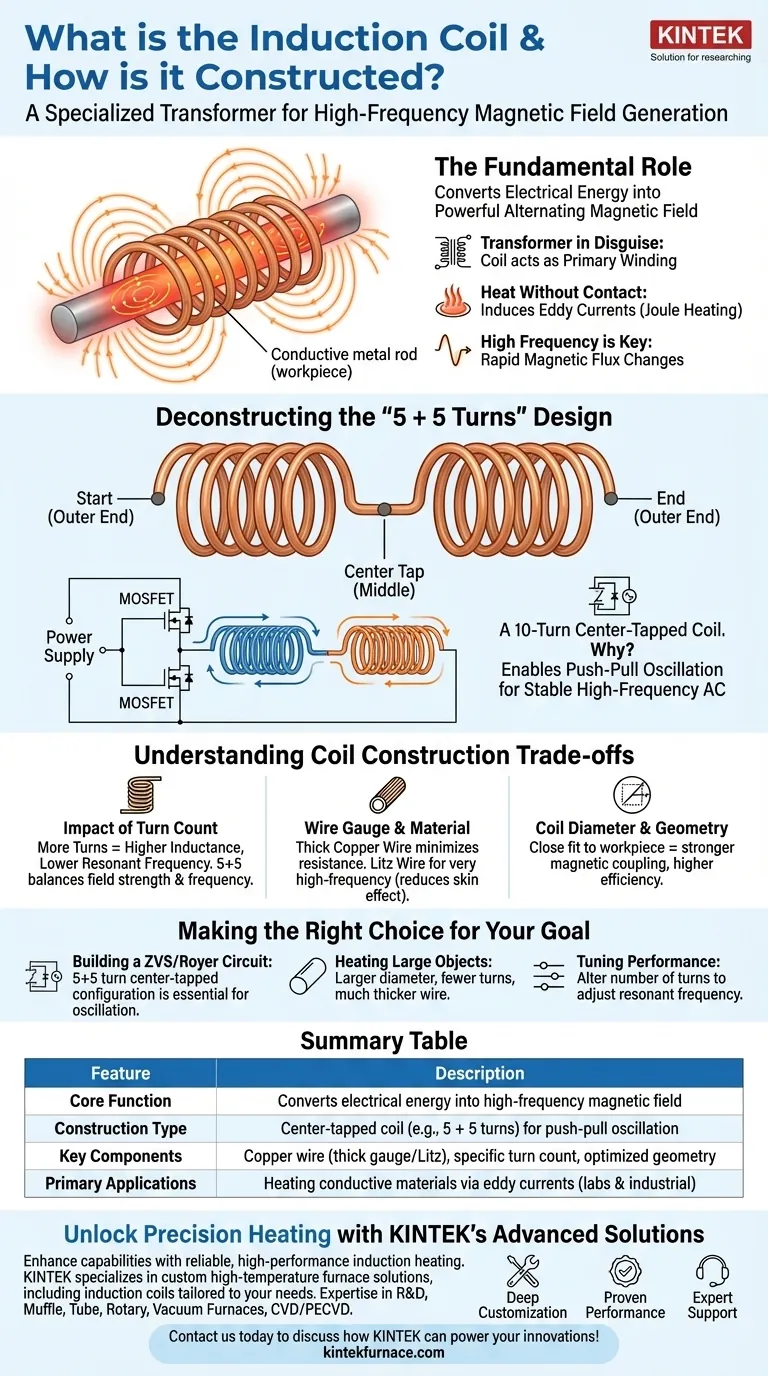

At its core, an induction coil is a specialized transformer that converts electrical energy into a powerful, alternating magnetic field. In the circuit described, its construction as a "5 + 5 turn" coil indicates it is a center-tapped coil, a specific design critical for creating the high-frequency alternating current needed for induction heating.

The "5 + 5 turns" specification is not simply a 10-turn coil. It describes a center-tapped coil with two identical 5-turn sections. This design is the engine of oscillation in many induction heater circuits, enabling a "push-pull" action that generates the required high-frequency magnetic field.

The Fundamental Role of the Induction Coil

An induction coil is the active component that performs the heating. It operates on the principle of electromagnetic induction, transferring energy to the workpiece without any physical contact.

A Transformer in Disguise

The coil acts as the primary winding of a transformer. When a high-frequency alternating current flows through it, it generates a rapidly changing magnetic field in the space within and around the coil.

Generating Heat Without Contact

When you place a conductive material (like a piece of steel) inside this magnetic field, the field induces powerful electrical currents within the metal, known as eddy currents. The metal's inherent resistance to the flow of these currents generates immense heat, a phenomenon called Joule heating.

The Importance of High Frequency

This process is only efficient at high frequencies. A static or slow-changing magnetic field would induce negligible current. Induction heaters typically operate at tens or hundreds of kilohertz to create the rapid magnetic flux changes needed for intense heating.

Deconstructing the "5 + 5 Turns" Design

The "5 + 5 turns" instruction is a precise blueprint for a very specific type of coil construction essential for common self-oscillating heater circuits.

What is a Center-Tapped Coil?

This specification describes a coil with a total of 10 turns, but with a connection point—the "tap"—made exactly in the middle, after the first 5 turns. You have three connection points: the start, the middle (center tap), and the end.

Why the Circuit Needs a Center Tap

In popular induction heater designs like a ZVS (Zero Voltage Switching) driver, the center tap is typically connected to the positive power supply. The two outer ends of the coil are then connected to electronic switches, such as MOSFETs.

How It Enables Oscillation

This configuration creates a push-pull system. The control circuit rapidly switches power between the two 5-turn sections. First, current flows through one half of the coil, and then the other, in a continuous back-and-forth oscillation. This action is what generates the stable, high-frequency AC required for the induction process.

Understanding the Trade-offs in Coil Construction

The design of the work coil is not arbitrary. Every parameter affects the heater's performance, efficiency, and safety.

The Impact of Turn Count

The number of turns directly influences the coil's inductance. More turns create a stronger magnetic field but also lower the circuit's resonant frequency. The "5 + 5" design is a common starting point that balances field strength and a sufficiently high operating frequency for general-purpose heating.

Wire Gauge and Material

The coil must carry very high currents. Using a thick copper wire (a low gauge number) is essential to minimize resistance and prevent the coil itself from overheating. For very high-frequency applications, specialized Litz wire may be used to overcome losses from the "skin effect."

Coil Diameter and Geometry

The coil should be sized to closely fit the workpiece. A large gap between the coil and the workpiece results in a weaker magnetic coupling and significantly less efficient heating. The shape of the coil can also be changed to concentrate the magnetic field on a specific area.

Making the Right Choice for Your Goal

The construction of your induction coil must be matched to the circuit's design and your heating objective.

- If your primary focus is building a ZVS or Royer circuit: The "5 + 5 turn" center-tapped configuration is a fundamental requirement for the circuit to oscillate correctly.

- If your primary focus is heating large objects: You will likely need a coil with a larger diameter and fewer turns, constructed from a much thicker gauge of wire to handle the increased power demands.

- If your primary focus is tuning performance: Altering the number of turns is the most direct way to change the resonant frequency of the tank circuit, which can be adjusted to better match the properties of the material you are heating.

Understanding that the coil is not just a component but the core of the resonant system is the key to mastering your induction heater's performance.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | Converts electrical energy into a high-frequency magnetic field for induction heating |

| Construction Type | Center-tapped coil (e.g., 5 + 5 turns) for push-pull oscillation in circuits like ZVS drivers |

| Key Components | Copper wire (thick gauge or Litz wire), specific turn count, and geometry tailored to the workpiece |

| Primary Applications | Heating conductive materials via eddy currents, used in labs and industrial settings for precise thermal processing |

Unlock Precision Heating with KINTEK's Advanced Solutions

Are you looking to enhance your laboratory's capabilities with reliable, high-performance induction heating? KINTEK specializes in providing custom high-temperature furnace solutions, including induction coils and systems tailored to your unique experimental needs. Our expertise in R&D and in-house manufacturing ensures you get durable, efficient equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems.

Why Choose KINTEK?

- Deep Customization: We design coils and furnaces to match your specific heating requirements, improving efficiency and results.

- Proven Performance: Benefit from our advanced technologies that deliver uniform heating and precise temperature control.

- Expert Support: From selection to implementation, our team is here to help you achieve optimal outcomes.

Don't let inefficient heating hold you back—contact us today to discuss how KINTEK can power your innovations and streamline your processes!

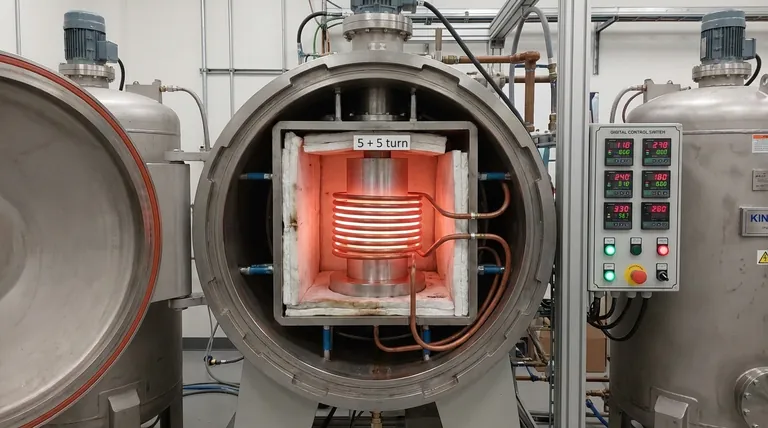

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials