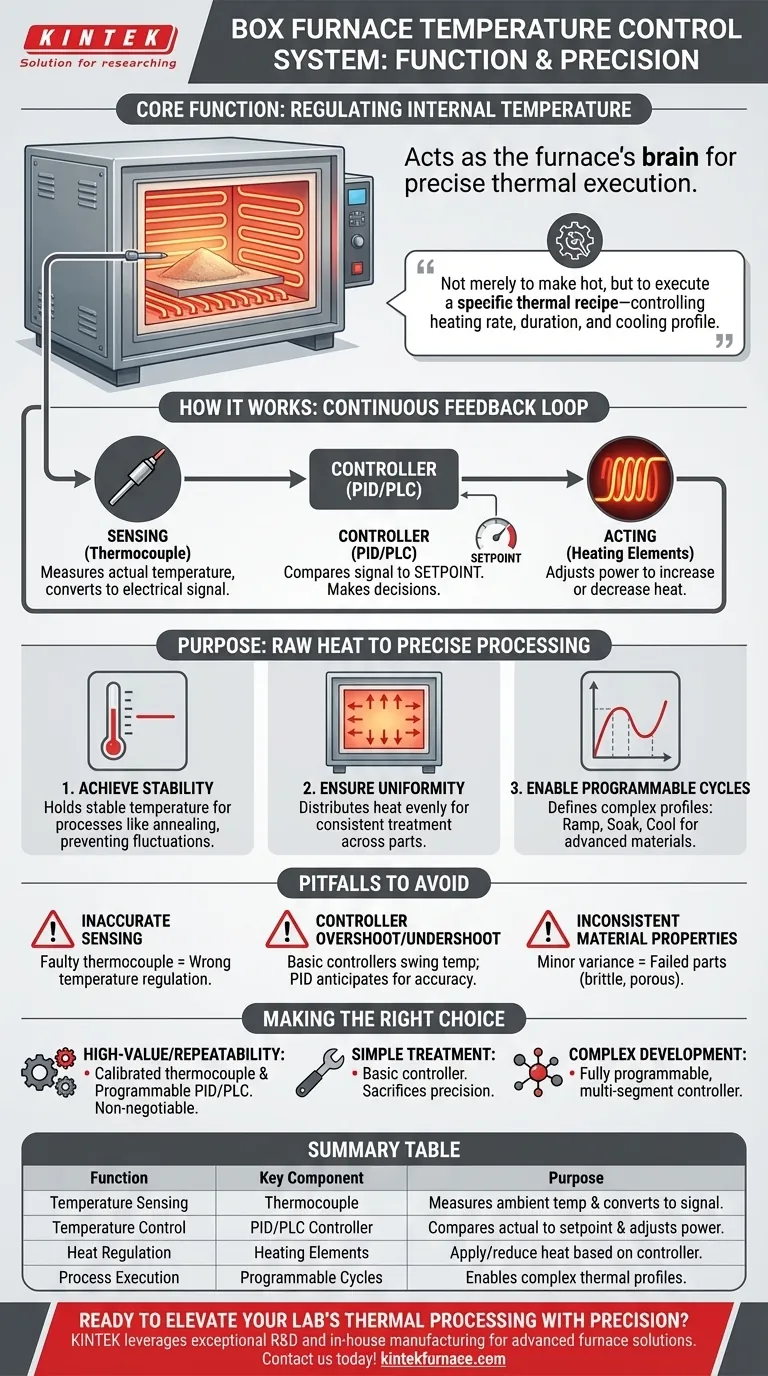

At its core, the function of a temperature control system in a box furnace is to precisely regulate the internal temperature according to a predetermined plan. It acts as the furnace's brain, constantly monitoring and adjusting the heat to ensure materials are processed under exact thermal conditions.

The system's true purpose is not merely to make the furnace hot, but to execute a specific thermal recipe—controlling the rate of heating, the duration at a set temperature, and the cooling profile—to achieve desired changes in a material's properties.

How the Temperature Control System Works

The system operates on a continuous feedback loop, a conversation between sensing, deciding, and acting. This process ensures the temperature you set is the temperature your material actually experiences.

Sensing the Temperature

The process begins with a sensor, most commonly a thermocouple, placed inside the furnace chamber. This device measures the ambient temperature and converts that thermal energy reading into a small electrical signal.

The Role of the Controller

This electrical signal is sent to the temperature controller. The controller's primary job is to compare the real-time temperature signal from the thermocouple to the desired temperature, known as the setpoint.

Modern furnaces often use sophisticated controllers (such as PID, PLC, or touch-screen) that can be programmed with multi-step thermal cycles.

Regulating the Heating Elements

Based on the difference between the actual temperature and the setpoint, the controller makes a decision. It then adjusts the amount of electrical power delivered to the heating elements lining the furnace walls, either increasing power to raise the temperature or decreasing it to maintain or lower the temperature.

The Purpose: From Raw Heat to Precise Processing

Simply generating heat is easy; controlling it with precision is what makes a box furnace a critical tool for science and industry. The control system is what enables this precision.

Achieving Temperature Stability

The most fundamental goal is to hold a stable temperature. For processes like annealing or aging, maintaining a specific temperature for hours without significant fluctuation is critical for achieving the intended metallurgical changes.

Ensuring Temperature Uniformity

Advanced control systems help ensure heat is distributed evenly throughout the chamber. This temperature uniformity is vital for guaranteeing that an entire batch of parts, or a single large component, receives the exact same thermal treatment from end to end.

Enabling Programmable Cycles

The true power of modern control systems lies in programmability. They allow users to define complex heating profiles, such as a rapid ramp-up to one temperature, a long hold (or "soak"), followed by a slow, controlled cooling phase. This is essential for processes like sintering and advanced ceramics manufacturing.

Understanding the Trade-offs and Pitfalls

The effectiveness of the entire furnace hinges on the quality of its control system. A failure in any part of the loop can compromise your results.

Inaccurate Temperature Sensing

The entire system trusts the thermocouple. If the sensor is poorly calibrated, degraded, or improperly placed, the controller will be regulating to the wrong temperature, leading to inconsistent or failed material processing.

Controller Overshoot and Undershoot

A basic controller might simply turn the heat on and off, causing the temperature to swing above and below the setpoint. A more advanced PID (Proportional-Integral-Derivative) controller anticipates these swings and makes finer power adjustments, holding the temperature with much greater accuracy.

The Impact on Material Properties

Inconsistent temperature control leads directly to inconsistent material outcomes. A variance of even a few degrees can be the difference between a properly hardened steel component and a brittle one, or a fully sintered ceramic and a porous, weak one. Lack of precision undermines process repeatability.

Making the Right Choice for Your Process

Understanding the control system empowers you to select the right equipment and diagnose issues. Your application dictates the level of control you need.

- If your primary focus is repeatability and high-value materials: A system with a calibrated thermocouple and a programmable PID or PLC controller is non-negotiable for consistent results.

- If your primary focus is simple heat treatment or burn-off: A basic controller that maintains a general temperature range may be sufficient, but you sacrifice precision.

- If your primary focus is complex material development: You require a fully programmable, multi-segment controller that allows for precise, repeatable thermal cycles to test and create new material properties.

Mastering the temperature control system gives you direct command over the final properties of your materials.

Summary Table:

| Function | Key Component | Purpose |

|---|---|---|

| Temperature Sensing | Thermocouple | Measures ambient temperature and converts it to an electrical signal |

| Temperature Control | PID/PLC Controller | Compares actual temperature to setpoint and adjusts power to heating elements |

| Heat Regulation | Heating Elements | Apply or reduce heat based on controller decisions to maintain desired temperature |

| Process Execution | Programmable Cycles | Enables complex thermal profiles for precise material property changes |

Ready to elevate your lab's thermal processing with precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to meet your unique experimental needs—ensuring consistent results and enhanced efficiency. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?