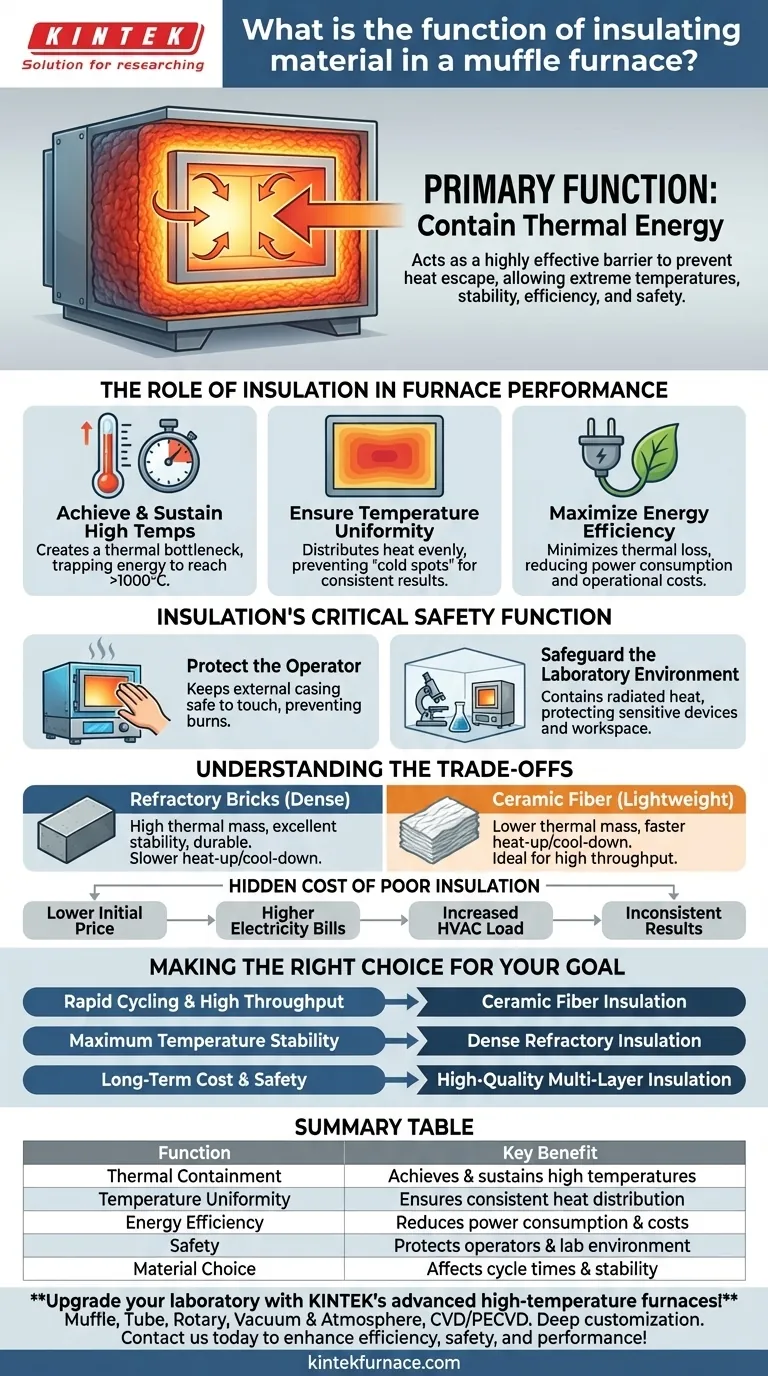

At its core, the insulating material in a muffle furnace serves one primary function: to contain thermal energy. By acting as a highly effective barrier, the insulation prevents heat from escaping the internal chamber. This containment is what allows the furnace to achieve extremely high temperatures, maintain them with stability, and operate both efficiently and safely.

Insulation is not merely a passive component; it is the critical enabler that allows a muffle furnace to achieve extreme temperatures, maintain the thermal stability required for repeatable results, and ensure a safe operating environment.

The Role of Insulation in Furnace Performance

The quality and design of the insulation directly dictate the furnace's capabilities. It moves the furnace from a simple heated box to a precision scientific instrument.

Achieving and Sustaining High Temperatures

A muffle furnace generates intense heat, often exceeding 1000°C, using electrical resistance heating elements. Without effective insulation, this heat would dissipate into the surrounding environment almost as fast as it is generated, making it impossible to reach or hold the target temperature.

The insulation creates a thermal bottleneck, trapping the energy and allowing the chamber temperature to build to the required level.

Ensuring Temperature Uniformity

For scientific and industrial processes, consistency is paramount. High-quality insulation ensures that heat is distributed evenly throughout the chamber, preventing "cold spots."

This thermal uniformity is critical for ensuring that an entire sample or batch of materials receives the exact same heat treatment, leading to reliable and repeatable results.

Maximizing Energy Efficiency

Heat that escapes the furnace is wasted energy. By minimizing this thermal loss, the insulation significantly improves the furnace's energy efficiency.

A well-insulated furnace requires less power to maintain its setpoint temperature, leading to lower operational costs over the lifetime of the equipment.

Insulation's Critical Safety Function

Beyond performance, insulation serves a non-negotiable safety role for both operators and the surrounding laboratory.

Protecting the Operator

The internal temperature of the furnace can be hot enough to melt metal. The insulation ensures that the external casing or body of the furnace remains at a safe temperature, often cool to the touch.

This layer of protection is essential for preventing severe burns and creating a safe working condition for laboratory personnel.

Safeguarding the Laboratory Environment

A poorly insulated furnace would radiate an immense amount of heat into the room. This can raise the ambient temperature of the lab, potentially damaging other sensitive electronic devices or affecting the results of other experiments.

Proper insulation contains this heat within the furnace, protecting the integrity of the entire workspace.

Understanding the Trade-offs

Not all insulation is created equal. The type and thickness of the material represent a key design choice that involves distinct trade-offs.

Material Matters: Refractory vs. Fiber

Furnaces typically use either dense refractory bricks or lightweight ceramic fiber insulation.

Refractory bricks are extremely durable and have high thermal mass, offering excellent temperature stability. Ceramic fiber is lighter and has lower thermal mass, allowing for faster heat-up and cool-down cycles.

The Impact on Cycle Times

The choice of material directly impacts performance. A furnace lined with heavy refractory bricks will heat up and cool down more slowly due to its high thermal inertia.

Conversely, a furnace with lightweight fiber insulation can cycle through temperatures much more quickly, which is ideal for high-throughput applications.

The Hidden Cost of Poor Insulation

A furnace with inadequate insulation may have a lower initial purchase price, but it will incur higher long-term costs. These costs manifest as higher electricity bills, an increased heat load on the lab's HVAC system, and potentially inconsistent results from poor temperature uniformity.

Making the Right Choice for Your Goal

The ideal insulation strategy depends entirely on the intended application of the furnace.

- If your primary focus is rapid cycling and high throughput: A furnace with lightweight ceramic fiber insulation is likely the best choice due to its faster heat-up and cool-down capabilities.

- If your primary focus is maximum temperature stability for sensitive processes: A furnace with dense, heavy-duty refractory insulation will provide a more stable thermal environment once at temperature.

- If your primary focus is long-term cost and safety: Investing in a furnace with high-quality, multi-layer insulation is always the correct decision, as it minimizes energy waste and ensures a safer lab.

Ultimately, understanding the function of its insulation is key to mastering the performance, safety, and efficiency of your muffle furnace.

Summary Table:

| Function | Key Benefit |

|---|---|

| Thermal Containment | Achieves and sustains high temperatures efficiently |

| Temperature Uniformity | Ensures consistent heat distribution for reliable results |

| Energy Efficiency | Reduces power consumption and operational costs |

| Safety | Protects operators and lab environment from extreme heat |

| Material Choice | Affects cycle times and stability (e.g., refractory vs. fiber) |

Upgrade your laboratory with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met precisely. Contact us today to enhance efficiency, safety, and performance in your heat treatment processes!

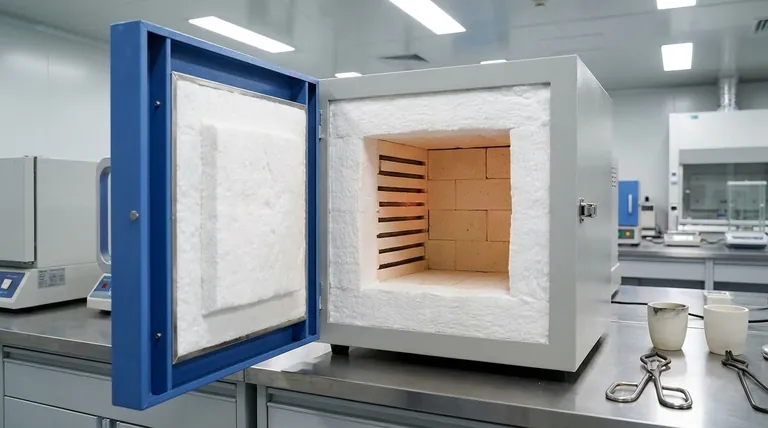

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production