At its core, a ceramic furnace is a high-temperature oven designed to transform ceramic materials into their final, hardened state. In dentistry, its primary function is to fire restorations like crowns, bridges, and veneers, using precisely controlled heat (and sometimes pressure) to achieve the necessary strength, fit, and aesthetic appearance for clinical use.

The true function of a ceramic furnace is not merely to heat, but to precisely manage the molecular transformation of a ceramic. It turns a fragile, pre-formed object into a final product with specific, engineered properties of hardness, dimensional accuracy, and aesthetics.

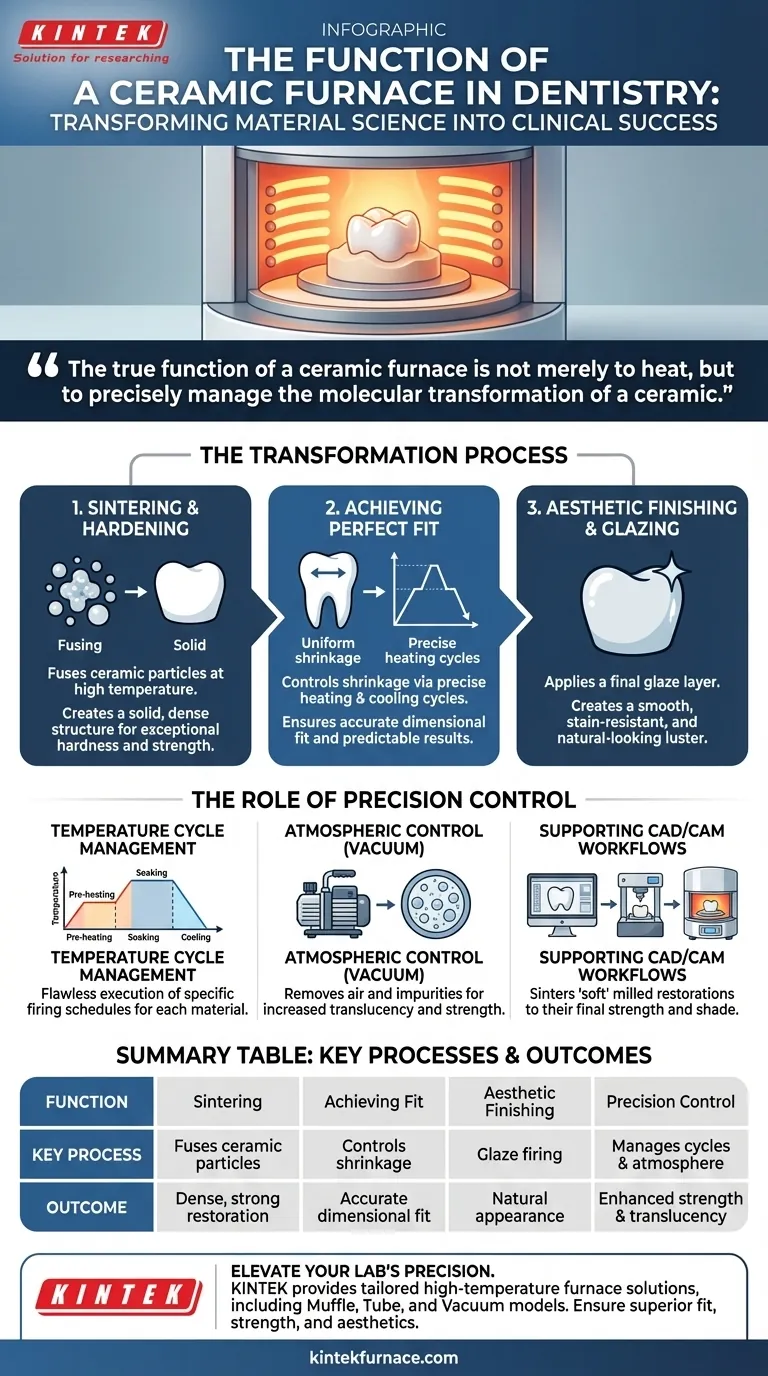

The Transformation Process: From Pre-Form to Prosthesis

A ceramic furnace is the final and most critical step in creating a durable dental restoration. The process it facilitates is far more complex than simple baking; it is a carefully controlled material science procedure.

Sintering and Hardening

The furnace's main job is to sinter the ceramic. This involves heating the material to a temperature high enough to fuse the ceramic particles together, creating a solid, dense structure without melting the material entirely.

This process is what gives the final restoration its exceptional hardness and ability to withstand the significant forces of chewing.

Achieving a Perfect Fit

Ceramic materials shrink during firing. A key function of the furnace is to manage this process through precise heating and cooling cycles.

By controlling the rate of temperature change, the furnace ensures that this shrinkage is uniform and predictable. This accuracy is paramount for creating a restoration that fits the patient's tooth perfectly, a requirement for long-term success.

Aesthetic Finishing and Glazing

Beyond structural integrity, the furnace is also used for aesthetic finishing. A final, lower-temperature "glaze" cycle melts a thin layer of glass on the surface of the restoration.

This glaze firing creates a smooth, stain-resistant, and natural-looking luster that mimics the appearance of real tooth enamel.

The Role of Precision Control

The quality of the final ceramic is directly tied to the furnace's ability to precisely control the firing environment. Modern furnaces are sophisticated instruments that manage multiple variables.

Temperature Cycle Management

Every ceramic has an ideal firing schedule. The furnace must execute this schedule flawlessly, including pre-heating, holding at a specific temperature (soaking), and controlled cooling.

Deviations from the prescribed cycle can result in a weak, porous, or cracked restoration, rendering it clinically useless.

Atmospheric Control

Many advanced furnaces also control the atmosphere inside the firing chamber, often by creating a vacuum.

Pulling a vacuum removes air and impurities that could get trapped in the ceramic, preventing discoloration and increasing the material's translucency and strength. This is especially critical for high-end aesthetic restorations.

Supporting CAD/CAM Workflows

In modern digital dentistry, a restoration is designed on a computer and milled from a block of ceramic material (CAD/CAM). However, this milled object is often in a "soft" state.

The furnace performs the final, essential step of sintering this milled restoration, bringing it to its full strength and final shade as specified by the material manufacturer.

Understanding the Operational Demands

While powerful, a ceramic furnace's performance is dependent on proper use and maintenance. Missteps can easily lead to failed restorations.

The Need for Calibration

To maintain accuracy, a furnace's temperature sensors must be calibrated regularly. An uncalibrated furnace that runs too hot or too cool will consistently produce poor fits, incorrect shades, and weak ceramics.

Material-Specific Programs

There is no "one-size-fits-all" firing program. Different ceramic materials (e.g., zirconia, lithium disilicate, porcelain) have vastly different requirements for temperature, time, and atmosphere. Using the wrong program for a given material is a primary cause of failure.

Investment and Maintenance

These are pieces of precision industrial equipment, not simple ovens. They represent a significant financial investment and require routine maintenance of components like the muffle (heating chamber), thermocouple, and vacuum pump to ensure consistent and reliable operation.

Matching the Furnace to Your Application

Choosing or using a ceramic furnace effectively depends entirely on your specific goals and workflow.

- If your primary focus is high-volume production: Prioritize furnaces with larger firing chambers and validated, efficient programs to maximize throughput without sacrificing quality.

- If your primary focus is high-aesthetic anterior crowns: Seek furnaces with advanced vacuum control and highly customizable programming to fine-tune translucency and color.

- If your primary focus is integrating with a CAD/CAM system: Ensure the furnace has approved, pre-set programs for the specific ceramic blocks you intend to mill to guarantee predictable results.

Ultimately, the ceramic furnace is the critical instrument that translates material science into clinical success.

Summary Table:

| Function | Key Process | Outcome |

|---|---|---|

| Sintering and Hardening | Fuses ceramic particles at high temperature | Dense, strong restoration |

| Achieving Perfect Fit | Controls shrinkage via precise heating/cooling cycles | Accurate dimensional fit |

| Aesthetic Finishing | Glaze firing for surface luster | Natural, stain-resistant appearance |

| Precision Control | Manages temperature cycles and atmosphere | Enhanced strength and translucency |

| CAD/CAM Support | Sinters milled restorations to final state | Full strength and shade accuracy |

Elevate your dental lab's precision and efficiency with KINTEK's advanced ceramic furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide tailored high-temperature furnaces, including Muffle, Tube, and Vacuum & Atmosphere models, designed to meet the unique demands of dental professionals. Our deep customization capabilities ensure your restorations achieve superior fit, strength, and aesthetics. Contact us today to discuss how our solutions can optimize your workflow and deliver consistent, high-quality results for crowns, bridges, and veneers!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time