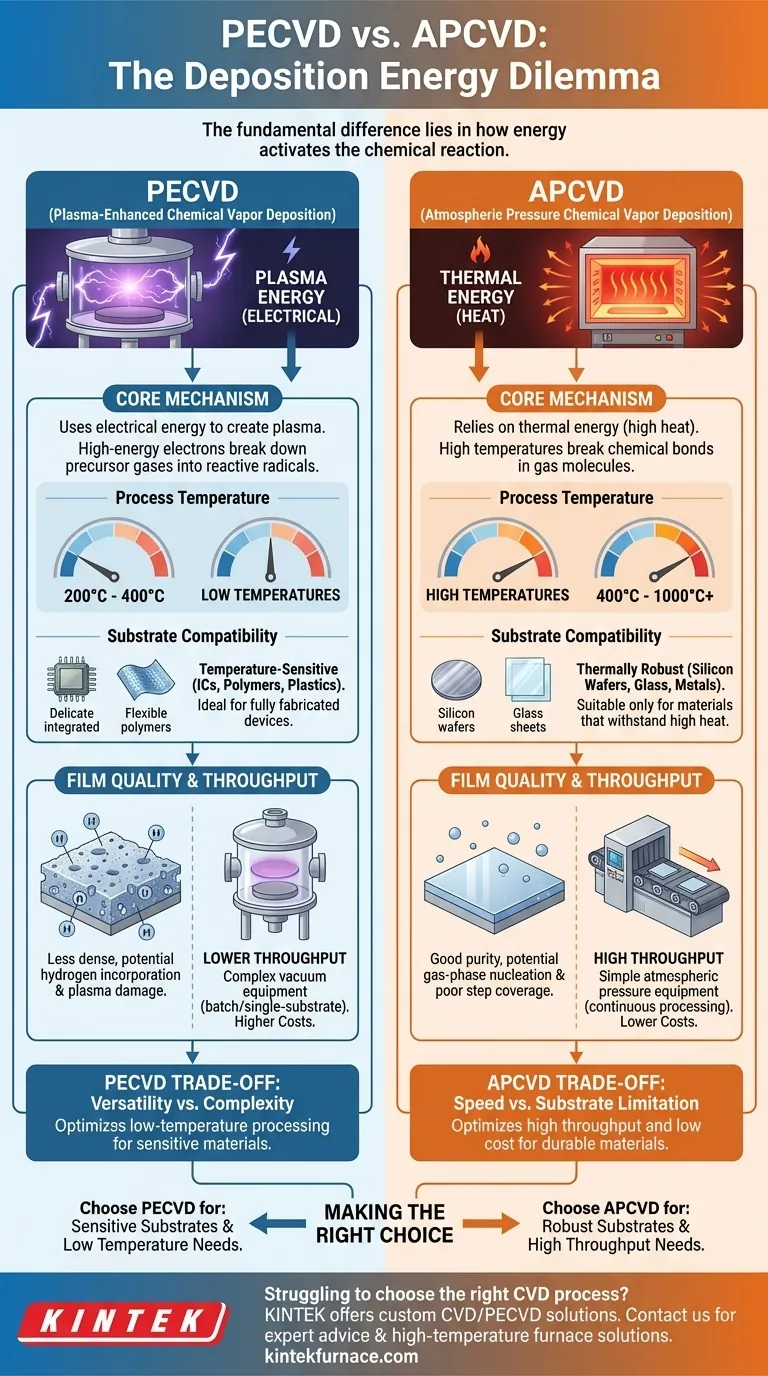

The fundamental difference between Plasma-Enhanced Chemical Vapor Deposition (PECVD) and Atmospheric Pressure Chemical Vapor Deposition (APCVD) lies in how each process supplies the energy needed to initiate the chemical reaction. APCVD uses high temperatures (thermal energy) to break down precursor gases, while PECVD uses an energized plasma at much lower temperatures to achieve the same goal. This single difference in energy source dictates the operating conditions, equipment, and suitable applications for each method.

Choosing between these two methods is a classic engineering trade-off. APCVD prioritizes high throughput and simplicity at the cost of high processing temperatures, whereas PECVD prioritizes low-temperature processing for sensitive materials at the cost of system complexity and potential plasma-induced effects.

The Core Mechanism: Plasma vs. Thermal Energy

To understand which method fits your goal, you must first understand how each one activates the deposition process. The energy source is the defining characteristic.

How APCVD Works: The Thermal Approach

APCVD relies on thermal energy (heat) to drive the chemical reaction. Precursor gases are introduced into a reaction chamber that is held at atmospheric pressure and heated to high temperatures, typically ranging from 400°C to over 1000°C.

This intense heat provides the necessary activation energy to break the chemical bonds in the gas molecules. The reactive chemical species then diffuse to the substrate surface, where they react to form the desired solid thin film.

Because it operates at atmospheric pressure, the equipment can be relatively simple. This often allows for continuous, conveyor-style processing, making it a high-throughput method.

How PECVD Works: The Plasma-Enhanced Approach

PECVD uses electrical energy to create a plasma, which is a partially ionized gas containing highly energetic electrons. The process is conducted in a vacuum chamber at significantly lower temperatures than APCVD, often between 200°C and 400°C.

An alternating electric field (typically radio frequency or RF) is applied to the precursor gases, stripping electrons from some gas molecules. These high-energy electrons then collide with other gas molecules, breaking them into reactive radicals without needing high heat.

These radicals are chemically very active and readily react on the relatively cool substrate surface to form the film. The lower temperature makes PECVD essential for depositing films on substrates that cannot withstand the thermal budget of APCVD.

Key Process and Film Property Comparisons

The difference in energy source creates significant distinctions in temperature, film quality, and production efficiency.

Deposition Temperature

This is the most critical differentiator. APCVD is a high-temperature process, making it suitable only for thermally robust substrates like silicon wafers early in their processing, glass, or certain metals.

PECVD is a low-temperature process. Its primary advantage is its ability to deposit films on fully fabricated devices with metal interconnects, plastics, or other materials that would be damaged or melted by high temperatures.

Film Quality and Conformality

APCVD can produce films with good purity, but gas-phase nucleation (particles forming in the gas before reaching the substrate) can be an issue due to the high temperatures and pressure. Step coverage, or the ability to coat complex 3D structures uniformly, can be poor.

PECVD films are often less dense than thermally grown films and can have significant amounts of hydrogen incorporated from precursor gases (e.g., SiH₄), which can affect film stress and electrical properties. Plasma can also cause ion bombardment damage to the substrate surface.

Throughput and Cost

APCVD is the clear winner for high throughput. Its atmospheric pressure operation allows for simple, low-cost, and often continuous processing systems, leading to a very low cost per substrate.

PECVD is a vacuum-based process, which requires more complex and expensive equipment (vacuum pumps, load locks). It is typically a batch or single-substrate process, resulting in lower throughput and higher capital and operational costs.

Understanding the Trade-offs

Neither technology is inherently superior; each represents a set of compromises optimized for different outcomes.

The APCVD Compromise: Speed vs. Substrate Limitation

With APCVD, you gain tremendous speed and low operational cost. However, you are strictly limited to substrates that can survive the high processing temperatures. It is a workhorse for applications where throughput is paramount and the substrate is durable.

The PECVD Compromise: Versatility vs. Complexity

PECVD provides the critical advantage of low-temperature processing, opening up a vast range of applications on sensitive substrates. This versatility comes at the price of slower throughput, higher equipment cost, and potential film quality issues like hydrogen incorporation and plasma damage that must be carefully managed.

Making the Right Choice for Your Application

Your choice depends entirely on your project's primary constraints: the substrate's thermal tolerance and your production volume requirements.

- If your primary focus is high-volume production on thermally robust substrates (like initial coatings on glass for solar cells or displays): APCVD is the clear choice for its unmatched throughput and cost-effectiveness.

- If your primary focus is depositing dielectric or passivation layers on temperature-sensitive devices (like completed integrated circuits or polymer-based electronics): PECVD is the only viable option, as its low temperature prevents damage to the underlying structures.

- If your primary focus is the absolute highest film quality and purity for critical electronic layers (and the substrate can tolerate heat): You may also consider other thermal methods like Low-Pressure CVD (LPCVD), which often provides superior conformality and lower contamination than either APCVD or PECVD.

Understanding this core distinction between thermal and plasma energy is the key to selecting the most effective and efficient deposition strategy for your project.

Summary Table:

| Feature | APCVD | PECVD |

|---|---|---|

| Energy Source | Thermal (High Temperature) | Plasma (Electrical) |

| Process Temperature | 400°C - 1000°C+ | 200°C - 400°C |

| Operating Pressure | Atmospheric | Low Pressure (Vacuum) |

| Substrate Compatibility | Thermally robust (Silicon, Glass) | Temperature-sensitive (ICs, Polymers) |

| Throughput | High (Continuous Processing) | Lower (Batch Processing) |

| Film Quality | Good purity, potential gas-phase nucleation | Less dense, potential hydrogen incorporation |

| Cost | Lower operational cost | Higher capital and operational cost |

Struggling to choose the right CVD process for your sensitive materials or high-throughput needs? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including custom CVD/PECVD systems. Our deep customization capabilities ensure your equipment precisely meets unique experimental requirements—whether you need low-temperature PECVD for delicate substrates or high-throughput APCVD for robust materials. Contact our experts today to discuss how we can optimize your thin-film deposition process.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition