The design basis of an SCR Type Silicon Carbide (SiC) heating element is to create a component specifically optimized for advanced thermal management systems that require a high degree of control and energy efficiency. It is a calculated enhancement of the U-shaped SiC rod, engineered to work seamlessly with Silicon-Controlled Rectifier (SCR) power controllers in technically demanding applications.

The key distinction is that an SCR Type element is not designed for simple, continuous heating. Instead, its electrical and thermal properties are engineered to respond precisely to the rapid power adjustments of an electronic SCR controller, enabling sophisticated and automated temperature management.

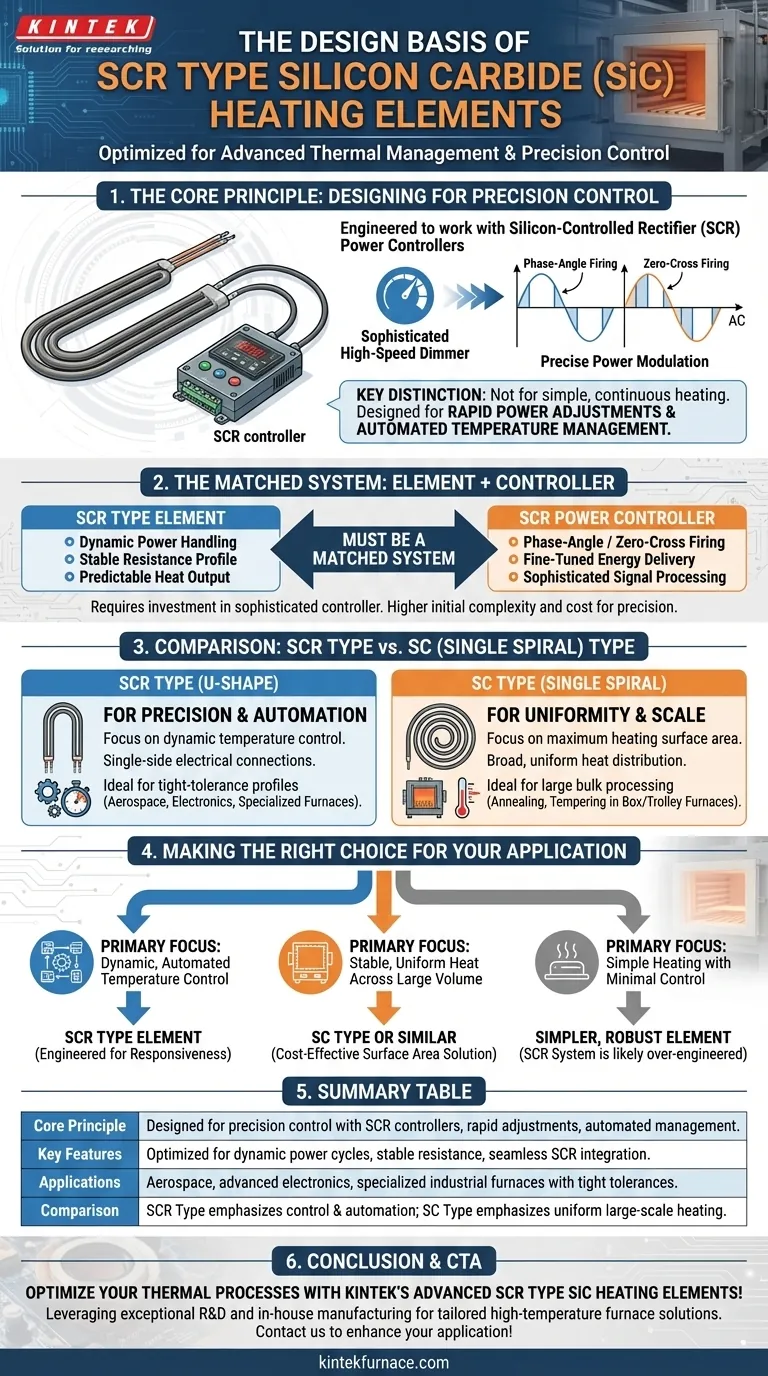

The Core Principle: Designing for Precision Control

The "SCR" in the name is the most critical part of its design basis. It refers to a Silicon-Controlled Rectifier, an electronic component that allows for highly precise and rapid modulation of electrical power. The entire element is designed around this control method.

The Role of the SCR Controller

An SCR power controller acts like a sophisticated, high-speed dimmer switch for the heating element, as opposed to a simple on/off switch.

It enables phase-angle firing or zero-cross firing, methods that precisely chop up the AC power waveform. This allows for extremely fine-tuned adjustments to the energy delivered to the element, resulting in superior temperature control.

Optimizing the Element for Dynamic Power

The SCR Type element's design is optimized to handle these rapid power cycles without degradation. Its material composition and geometry are calculated to provide a stable resistance profile under fluctuating electrical loads.

This ensures that the heat output is predictable and directly proportional to the controller's signal, which is essential for automated systems in aerospace, advanced electronics, and specialized industrial furnaces.

The Foundation of Joule Heating

At its core, the element still operates on the principle of Joule heating, where resistance to an electrical current generates heat.

However, the SCR Type's design basis is focused on making this heat generation exceptionally controllable, allowing for a level of management that simpler element designs cannot achieve.

SCR Type vs. SC (Single Spiral) Type

Understanding the design basis of the SCR Type becomes clearer when contrasted with other common designs, like the SC (Single Spiral) Type. They are engineered for different purposes.

SCR Type: For Precision and Automation

The SCR Type is designed for processes where temperature must be adjusted quickly and accurately. The U-shape allows for electrical connections on a single side, simplifying furnace wiring and construction in complex equipment.

Its home is in high-end applications where automated, tight-tolerance thermal profiles are mission-critical.

SC Type: For Uniformity and Scale

The SC (Single Spiral) Type has a different design basis: to provide maximum heating surface area for broad, uniform heat distribution.

This design is ideal for large box furnaces or trolley furnaces used in processes like annealing or tempering, where maintaining a consistent temperature across a large volume is more important than making rapid adjustments.

Understanding the Trade-offs

Choosing an SCR Type element involves acknowledging its specific purpose and limitations. It is not a universal solution.

The Requirement of a System Approach

The element and the SCR controller are a matched system. You cannot gain the benefits of an SCR Type element by simply wiring it to a basic on/off contactor. The investment must include the sophisticated power controller.

Complexity and Cost

This system-level approach naturally brings higher initial costs and complexity compared to simpler heating setups. The precision it offers is a direct trade-off for increased engineering and component costs.

General SiC Material Properties

Like all silicon carbide elements, the SCR Type is hard and brittle. It is resistant to thermal shock and will not deform at high temperatures, but it requires careful handling and installation to prevent mechanical fracture.

Making the Right Choice for Your Application

Selecting the correct heating element requires aligning its fundamental design basis with your primary operational goal.

- If your primary focus is dynamic, automated temperature control for sophisticated processes: The SCR Type is engineered specifically for this purpose and will provide the necessary responsiveness.

- If your primary focus is achieving stable, uniform heat across a large furnace for bulk processing: An SC (Single Spiral) Type or a similar design focused on surface area is the more direct and cost-effective solution.

- If your primary focus is simple heating with minimal control requirements: The SCR Type system is likely over-engineered for your needs, and a simpler, more robust element design would be a better fit.

Ultimately, choosing the right element begins with understanding that its design must match the control strategy of your entire heating system.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Designed for precision control with SCR power controllers, enabling rapid power adjustments and automated temperature management. |

| Key Features | Optimized for dynamic power cycles, stable resistance profile, and seamless integration with SCR controllers for high-end applications. |

| Applications | Ideal for aerospace, advanced electronics, and specialized industrial furnaces requiring tight thermal tolerances. |

| Comparison | SCR Type focuses on control and automation, while SC Type emphasizes uniform heating for large-scale processes. |

Optimize your thermal processes with KINTEK's advanced SCR Type SiC heating elements! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior efficiency and control. Contact us today to discuss how we can enhance your application!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability