In conclusion, muffle furnaces are indispensable laboratory and industrial tools for applications requiring precise, high-temperature heating in a contamination-free environment. Their core value is the ability to thermally process materials without exposing them to the byproducts of combustion, ensuring sample purity and process repeatability.

The essential takeaway is that a muffle furnace's primary function is not just to get hot, but to deliver clean heat. By isolating the material inside a "muffle" chamber, it enables high-precision analysis and advanced manufacturing processes that would be impossible with direct-fired heating methods.

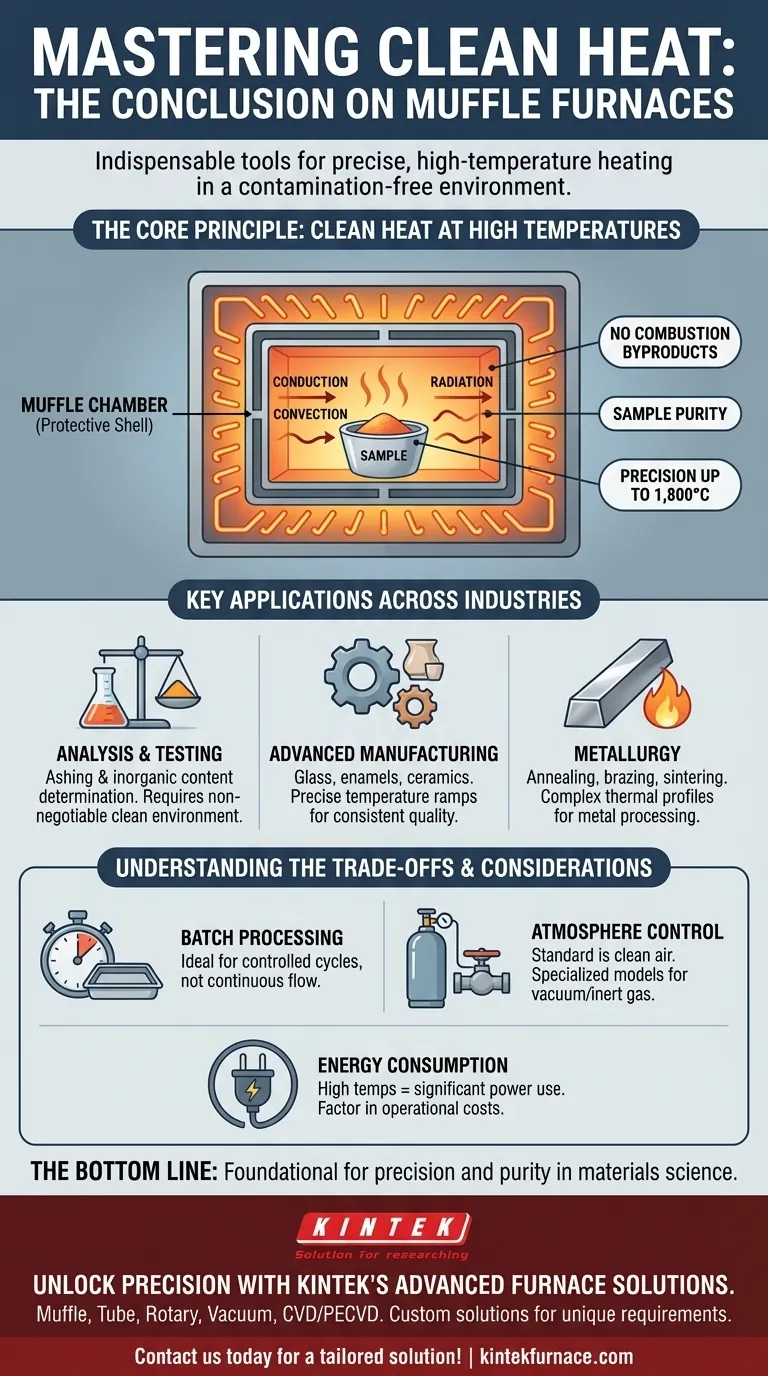

The Core Principle: Clean Heat at High Temperatures

A muffle furnace's design is centered on one fundamental goal: separating the material being processed from the source of heat. This separation prevents contamination and allows for extremely precise temperature control.

What "Muffle" Means: The Protective Chamber

The term "muffle" refers to the furnace's interior chamber, which is made from a heat-resistant material. This chamber shields the workpiece or sample from any harmful gases or particles that could be generated by the heating source, especially in older, fuel-fired designs.

How Modern Furnaces Achieve This

Modern muffle furnaces are typically electric. They use heating elements that heat the chamber through conduction, convection, and blackbody radiation. This design inherently eliminates the creation of combustion byproducts, providing a perfectly clean environment.

The Result: Unmatched Precision and Purity

This clean, enclosed environment allows for highly uniform and stable temperatures, often reaching up to 1,800°C (3,272°F). This combination of high heat and purity is critical for achieving reliable results in testing and consistent quality in manufacturing.

Key Applications Across Industries

The unique capabilities of muffle furnaces make them essential across a wide range of scientific and industrial fields. Their use can be broadly categorized into analysis, manufacturing, and advanced metallurgical processing.

For Material Analysis and Testing

The most common analytical use is ashing. To determine the inorganic ash content of a sample (like food, plastic, or coal), a muffle furnace incinerates all organic material at a high temperature, leaving only the ash behind for measurement. A clean environment is non-negotiable for an accurate result.

For Advanced Manufacturing

Industries rely on muffle furnaces for producing high-quality glass, enamels, and ceramics. These processes require slow, controlled temperature ramps and soak times to ensure the material cures properly without stress or defects.

For Sophisticated Metallurgical Processes

Muffle furnaces are central to modern metallurgy. They are used for processes like:

- Annealing: Softening metals to improve their workability.

- Brazing: Joining metal parts using a filler metal.

- Sintering: Fusing powdered materials (like in metal injection molding) into a solid piece by applying heat below the melting point.

Understanding the Trade-offs

While incredibly versatile, muffle furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Batch Processing vs. Continuous Flow

Most muffle furnaces are designed for batch processing. You load a sample, run a heating cycle, and then unload it. This makes them unsuitable for high-volume, continuous manufacturing lines, which often require larger, custom-built tunnel kilns.

Atmosphere Control Requires Specialization

A standard muffle furnace provides a clean air environment. If your process requires a specific controlled atmosphere—such as a vacuum or an inert gas like argon—you will need a more specialized and expensive model designed for that purpose.

Energy Consumption

Reaching and maintaining temperatures of 1000°C or more requires a significant amount of electrical energy. The operational cost, particularly for large or frequently used furnaces, is a practical consideration for any lab or facility.

Making the Right Choice for Your Goal

The "best" use of a muffle furnace depends entirely on your specific objective.

- If your primary focus is accurate material analysis (like ashing): The furnace's most important feature is its ability to provide a clean, inert heating environment to ensure your results are not skewed by contamination.

- If your primary focus is custom manufacturing (ceramics, glass): The critical value lies in the furnace's precise and repeatable temperature programming, which ensures consistent product quality from batch to batch.

- If your primary focus is advanced metallurgy (sintering, debinding): You need a furnace that not only reaches extreme temperatures but also offers the robust control required for complex, multi-stage thermal profiles.

Ultimately, the muffle furnace is a foundational tool that enables precision and purity in the world of materials science and engineering.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Clean Heat Environment | Prevents contamination, ensures sample purity | Material ashing, analytical testing |

| Precise Temperature Control | Uniform and stable heating up to 1,800°C | Ceramics manufacturing, glass production |

| Isolation in Muffle Chamber | Protects samples from combustion byproducts | Annealing, brazing, sintering in metallurgy |

| Batch Processing Design | Ideal for controlled, repeatable thermal cycles | Custom manufacturing, lab experiments |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on material analysis, custom manufacturing, or advanced metallurgy, our furnaces deliver clean heat, precise temperature control, and reliable performance to enhance your efficiency and results.

Ready to elevate your thermal processing? Contact us today for a tailored solution!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO