In the design of electric heating systems, surface load is the measure of power density, or the amount of heat energy being dissipated per unit of surface area. It is the single most important factor determining a heating element's operational temperature, its service life, and its effect on the material being heated. Getting this value right is the difference between a reliable, long-lasting system and one that fails prematurely.

The core challenge in thermal design is not just generating heat, but managing its transfer into the target medium. Surface load, expressed in watts per square centimeter (W/cm²) or watts per square inch (W/in²), is the critical metric that links an element's power to its physical size, directly dictating its lifespan and safety.

The Core Principle: From Power to Heat Transfer

To understand surface load, we must first understand how heat is generated and why its concentration matters.

Generating Heat

All resistive heating elements operate on a simple principle: when electric current flows through a material with resistance, electrical energy is converted into thermal energy. This is the fundamental heating effect of electric current.

The total power generated is measured in watts (W). However, this number alone tells you nothing about the intensity of the heat.

Defining Surface Load

Surface load is calculated by dividing the element's total power output (in watts) by its total surface area (in cm² or in²).

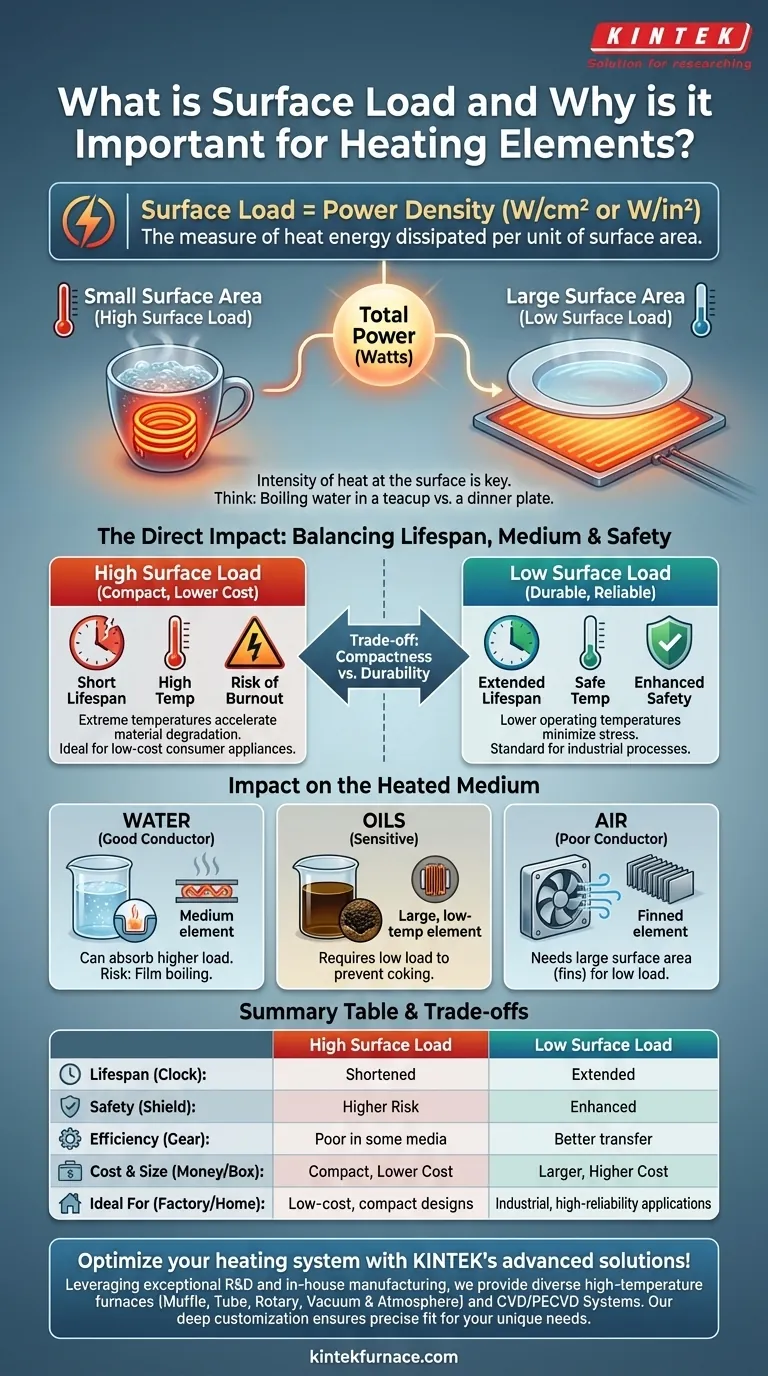

Think of it like this: pouring a liter of boiling water onto a large dinner plate versus into a small teacup. The total amount of heat is identical, but the intensity and temperature at the surface of the teacup will be far higher. Surface load is the "intensity" of the heat at the element's surface.

Why Area is the Critical Variable

For a given power requirement—say, 1000 watts—you can achieve that output with a small, compact element or a large, spread-out one.

A small element will have a low surface area and therefore a high surface load. A large element will have a high surface area and a low surface load. This choice has profound consequences.

The Direct Impact of Surface Load

The value you choose for surface load directly impacts the element itself, the material you are heating, and the overall system's safety.

Element Lifespan and Temperature

A high surface load forces the element's sheath to reach a very high temperature to dissipate its heat into the surrounding medium. This extreme temperature accelerates oxidation and material degradation, drastically shortening the element's service life.

Conversely, a low surface load allows the element to transfer the same amount of power at a much lower, safer operating temperature. This minimizes material stress and leads to a significantly longer, more reliable service life.

Impact on the Heated Medium

The appropriate surface load is dictated by the material being heated.

- Water: Can absorb heat well, allowing for a relatively high surface load. However, if the load is too high, it can cause film boiling, where a layer of steam insulates the element, preventing heat transfer and causing it to overheat and fail.

- Oils: Require a much lower surface load. If the element surface is too hot, it will "coke" or carbonize the oil, fouling the element and ruining the product.

- Air: Is a poor thermal conductor. Heating air requires a very low surface load, which is why air heaters use fins to dramatically increase the surface area for effective heat transfer.

System Safety and Efficiency

An element with an excessively high surface load for its application will fail to transfer heat efficiently. This built-up thermal energy can lead to element burnout, damage to the surrounding equipment, and, in the worst cases, a fire hazard.

Understanding the Trade-offs

Choosing a surface load is always a matter of balancing performance, cost, and longevity.

High Surface Load: The Temptation of Compactness

The primary benefit of a high surface load is that it allows for a smaller, more compact, and often less expensive heating element for a given power output.

The unavoidable trade-off is a drastically reduced service life and a higher risk of damaging the medium being heated. This approach is often seen in low-cost consumer appliances where longevity is not the primary design driver.

Low Surface Load: The Pursuit of Durability

The primary benefit of a low surface load is a long, predictable service life and gentle heating of the target medium. This ensures system reliability and protects sensitive materials.

The trade-off is that the element must be physically larger, and therefore often more expensive and more difficult to fit into a compact design. This is the standard for industrial processes and high-reliability equipment.

Selecting the Right Surface Load for Your Application

Your final decision must be guided by the primary goal of your design.

- If your primary focus is longevity and reliability: Opt for the lowest practical surface load by using a physically larger element; this is the standard for industrial and critical applications.

- If your primary focus is a compact design or low initial cost: You may use a higher surface load, but you must accept the trade-off of a shorter lifespan and carefully test the interaction with the heated material.

- If you are heating a sensitive fluid like oil or a sugar solution: You must prioritize a very low surface load to prevent chemical breakdown (coking or caramelization) of the medium.

- If you are heating air or other gases: You must use an element with a large surface area (like a finned heater) to achieve the required low surface load for effective and safe heat transfer.

Ultimately, mastering surface load allows you to move beyond simply generating heat and begin engineering predictable, reliable, and safe thermal systems.

Summary Table:

| Aspect | High Surface Load | Low Surface Load |

|---|---|---|

| Element Lifespan | Shortened due to high temperatures | Extended with lower operating temperatures |

| Safety | Higher risk of burnout and hazards | Enhanced safety and reliability |

| Efficiency | Poor heat transfer in some media | Better heat transfer and protection of materials |

| Cost & Size | More compact and lower initial cost | Larger size and often higher cost |

| Ideal For | Low-cost, compact designs | Industrial, high-reliability applications |

Optimize your heating system with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs—enhance reliability and efficiency today. Contact us now to discuss how we can support your thermal design goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control