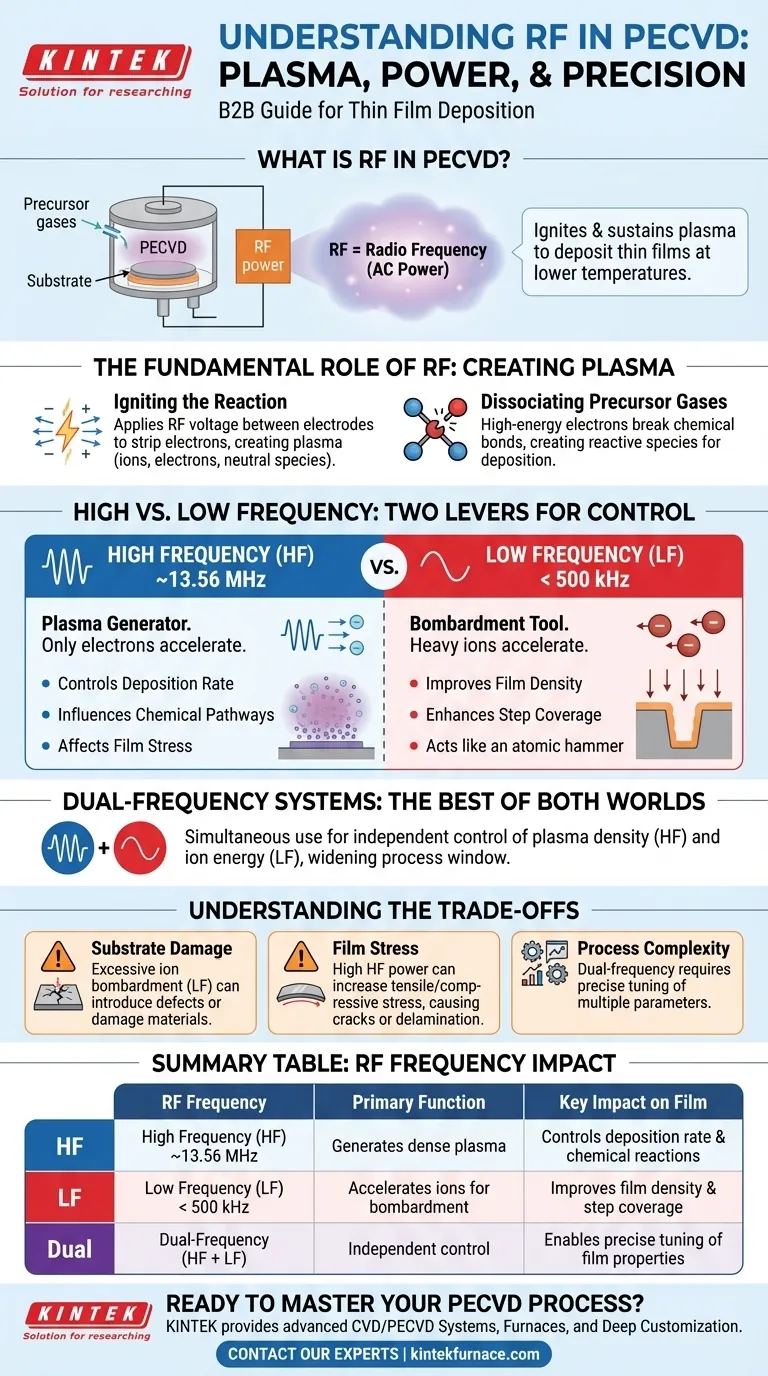

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), RF stands for Radio Frequency. This is the alternating current (AC) power source used to ignite and sustain a plasma, which is an energized gas containing ions and electrons. This plasma provides the energy needed to break down precursor gases and deposit a thin film onto a substrate at much lower temperatures than in traditional Chemical Vapor Deposition (CVD).

The choice of RF frequency in PECVD is not just a power switch; it is a critical control knob. High frequency (HF) is used to generate the reactive species for deposition, while low frequency (LF) is used to control the energy of ions bombarding the substrate, directly impacting the final film's physical properties.

The Fundamental Role of RF: Creating the Plasma

Igniting the Reaction

The PECVD process begins with introducing precursor gases into a vacuum chamber. An RF voltage is then applied between two electrodes inside the chamber.

This powerful electric field strips electrons from the gas atoms and molecules, creating a mixture of charged ions, electrons, and neutral species known as a plasma.

Dissociating Precursor Gases

The high-energy electrons within the plasma collide with the precursor gas molecules. These collisions are energetic enough to break the chemical bonds of the precursor molecules.

This dissociation creates the highly reactive chemical species that are the building blocks for the thin film that will be deposited onto the substrate surface.

High Frequency vs. Low Frequency: Two Levers for Control

The specific RF frequency used has a profound and distinct effect on the plasma and the resulting film. Most industrial systems use one or both of two standard frequency ranges.

High Frequency (HF) RF: The Plasma Generator (13.56 MHz)

At the standard high frequency of 13.56 MHz, the electric field oscillates so rapidly that the heavy ions in the plasma cannot keep up. Only the much lighter electrons are able to accelerate.

The primary effect of HF power is therefore the efficient generation of a dense plasma through electron collisions. This makes it the main tool for controlling the rate of deposition and the chemical reaction pathways. It also has a strong effect on the intrinsic stress of the deposited film.

Low Frequency (LF) RF: The Bombardment Tool (< 500 kHz)

At frequencies below 500 kHz, the electric field oscillates slowly enough for the heavier positive ions to respond and accelerate towards the electrodes.

When the substrate is placed on one of these electrodes, it is subjected to energetic ion bombardment. This physical process acts like an atomic-scale hammer, densifying the film as it grows. This is especially useful for improving step coverage, which is the ability of the film to conformally coat complex surface features like trenches.

Dual-Frequency Systems: The Best of Both Worlds

Modern PECVD systems often employ both HF and LF power sources simultaneously. This allows for independent control over plasma density (via HF power) and ion bombardment energy (via LF power).

This dual-lever approach provides a much wider and more precise process window, enabling engineers to decouple film growth rate from film properties like density and stress.

Understanding the Trade-offs

While RF control is powerful, it involves balancing competing factors. Understanding these trade-offs is key to a stable and successful deposition process.

The Risk of Substrate Damage

While the ion bombardment from LF RF is useful for densifying films and improving coverage, excessive bombardment can be destructive. It can introduce defects into the film or physically damage sensitive underlying substrate materials.

The Challenge of Film Stress

Using high levels of HF power to increase deposition rates can also increase the tensile or compressive stress in the film. If stress becomes too high, it can cause the film to crack, peel off the substrate, or cause the wafer to bow.

Process Complexity and Tuning

Dual-frequency systems offer superior control but also add complexity. Finding the optimal balance of HF and LF power, along with other parameters like gas flow and pressure, requires careful process development and characterization.

Making the Right Choice for Your Goal

Your RF strategy should be directly aligned with the desired properties of your final thin film.

- If your primary focus is depositing a uniform film on a flat substrate: Start with a standard single-frequency HF (13.56 MHz) process, as it efficiently generates the plasma needed for deposition while offering control over film stress.

- If your primary focus is achieving excellent step coverage in trenches or increasing film density: Incorporate LF RF or use a dual-frequency system to leverage controlled ion bombardment for physical assistance during deposition.

Mastering the use of RF transforms PECVD from a simple deposition technique into a precise engineering tool.

Summary Table:

| RF Frequency | Primary Function | Key Impact on Film |

|---|---|---|

| High Frequency (HF) ~13.56 MHz | Generates dense plasma via electron collisions | Controls deposition rate and chemical reactions |

| Low Frequency (LF) < 500 kHz | Accelerates ions for substrate bombardment | Improves film density and step coverage |

| Dual-Frequency (HF + LF) | Independent control of plasma density and ion energy | Enables precise tuning of film properties |

Ready to Master Your PECVD Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need to optimize film stress, achieve superior step coverage, or develop a new deposition process, our expertise can help you harness the full power of RF in your PECVD system.

Contact our experts today to discuss your specific application and discover how our tailored solutions can enhance your research and production outcomes.

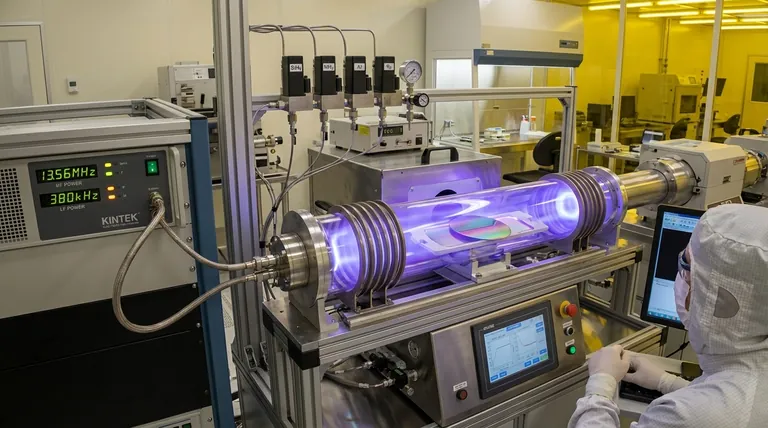

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab