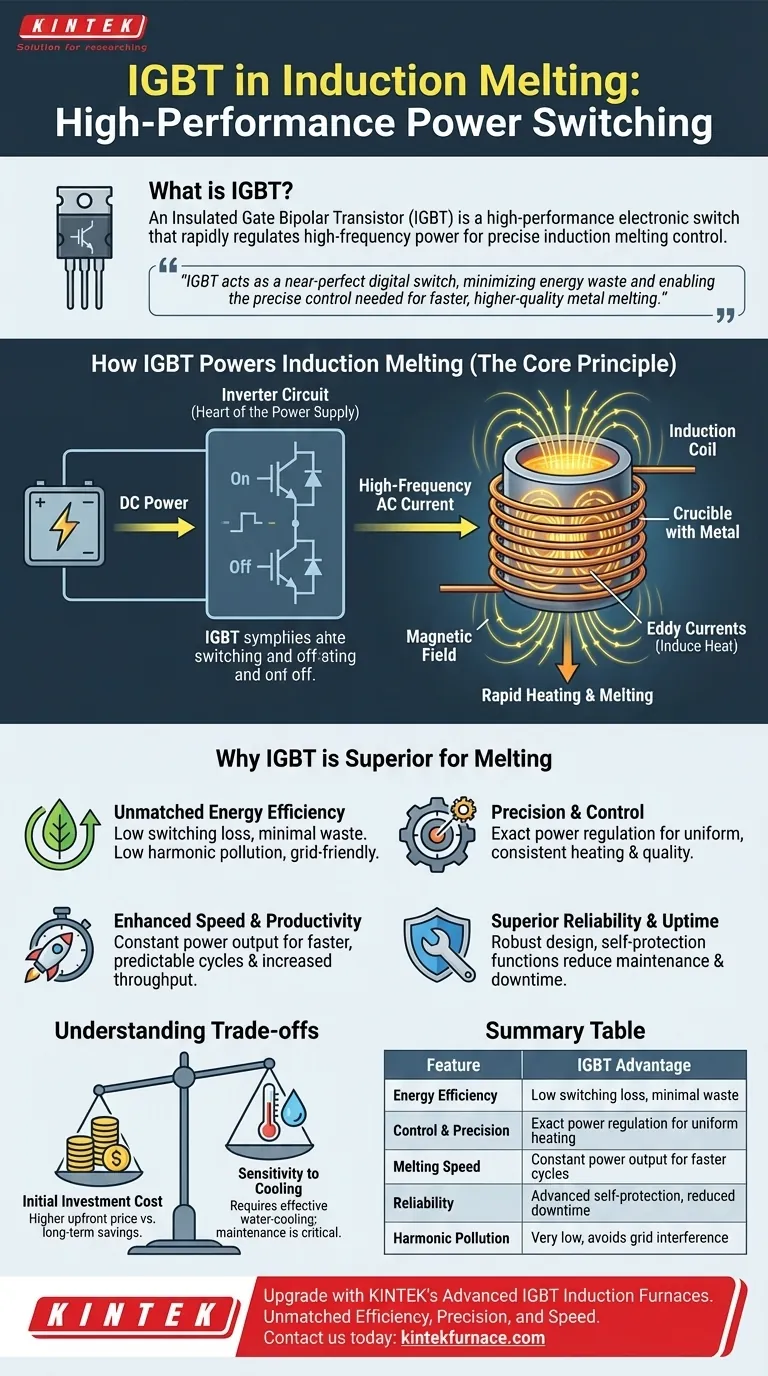

At its core, an Insulated Gate Bipolar Transistor (IGBT) is a high-performance electronic switch. In the context of induction melting, its function is to rapidly turn a powerful electrical current on and off, thousands of times per second. This precise switching action regulates the high-frequency power supplied to the furnace's induction coil, giving operators exact control over the entire melting process.

The central challenge in induction melting is converting standard electrical power into high-frequency energy efficiently and reliably. IGBT technology solves this by acting as a near-perfect digital switch, minimizing energy waste and enabling the precise control needed for faster, higher-quality metal melting.

The Core Principle: How IGBT Powers Induction Melting

An induction furnace works by creating a powerful, fluctuating magnetic field to heat metal. The IGBT is the critical component that makes this process efficient and controllable in modern systems.

From Transistor to High-Power Switch

An IGBT combines the best attributes of two other transistor types. It has the simple, low-power activation gate of a MOSFET, making it easy to turn on and off, but it also has the high-power, low-loss output capability of a bipolar junction transistor (BJT).

This hybrid design creates a highly efficient switch capable of handling immense currents while consuming very little energy to operate.

The Role of the Inverter Circuit

IGBTs are the heart of the power supply's inverter circuit. This circuit takes rectified DC power and "chops" it up, converting it back into a new, very high-frequency AC current.

The IGBTs switch on and off at a programmed frequency, creating the alternating current waveform that is fed directly to the induction coil wrapped around the crucible.

Generating the Magnetic Field

As this high-frequency AC current flows through the induction coil, it generates a powerful and rapidly reversing magnetic field in the center of the coil.

The speed at which the IGBTs switch directly determines the frequency of this magnetic field, which is a key parameter in optimizing the heating process for different metals.

Inducing Heat in the Metal

This intense magnetic field penetrates the metal placed inside the crucible. According to the principles of electromagnetic induction, the field induces powerful electrical currents, known as eddy currents, within the metal itself.

The metal's natural electrical resistance causes these eddy currents to generate immense heat, rapidly raising the metal's temperature to its melting point from the inside out.

Why IGBT Is a Superior Technology for Melting

Compared to older technologies like Silicon-Controlled Rectifier (SCR) systems, IGBT-based furnaces offer significant operational advantages that directly impact performance and profitability.

Unmatched Energy Efficiency

IGBTs switch with extremely low energy loss. This efficiency means more of the electricity drawn from the grid is converted into useful heat in the metal, and less is wasted.

Furthermore, these systems produce very low harmonic pollution. They don't distort the electrical grid, which prevents interference with other sensitive factory equipment and avoids potential utility penalties.

Precision and Control

The ability to precisely manage the IGBTs' switching frequency and duty cycle gives operators exact control over the power delivered to the melt.

This results in more accurate temperature management, uniform heating, and ultimately, a higher and more consistent quality of the final melted material.

Enhanced Speed and Productivity

A key feature of modern IGBT power supplies is their ability to maintain constant power output throughout the melt cycle.

Unlike older systems that lose efficiency as conditions change, an IGBT furnace delivers full power from start to finish. This results in faster, more predictable melting times and increased overall throughput.

Superior Reliability and Uptime

IGBT systems are built with robust, modern components and often include sophisticated self-protection functions. They can detect and react to issues like over-voltage or short circuits, preventing catastrophic failures.

This inherent reliability leads to significantly less maintenance and downtime, maximizing the furnace's operational availability.

Understanding the Trade-offs

While IGBT technology is a significant advancement, it's important to understand the full context of its implementation.

Initial Investment Cost

IGBT-based induction furnaces typically have a higher upfront purchase price compared to older, SCR-based systems or traditional fuel-fired furnaces.

This cost should be evaluated as a long-term investment. The savings from higher energy efficiency, increased productivity, and reduced maintenance often provide a clear and rapid return on the initial capital expenditure.

Sensitivity to Cooling

Like all high-power electronic components, IGBTs generate heat during operation and are sensitive to overheating. Their performance and lifespan depend on an effective cooling system, which is almost always a dedicated water-cooling circuit.

Failure of the cooling system can lead to a rapid failure of the IGBTs. Therefore, proper maintenance of the cooling loop, including water quality and flow, is critical for system reliability.

Making the Right Choice for Your Operation

Choosing the right melting technology depends on your specific operational priorities.

- If your primary focus is maximizing energy efficiency and reducing operational costs: IGBT technology is the definitive choice due to its low switching losses and clean power draw.

- If your primary focus is melt quality and process consistency: The precise power and temperature control offered by IGBT systems ensures uniform heating and repeatable results that are difficult to achieve with other methods.

- If your primary focus is high throughput and production speed: An IGBT furnace provides constant power output and faster cycle times, directly increasing your plant's production capacity.

Adopting IGBT technology is a strategic decision to modernize your melting process for greater efficiency, control, and reliability.

Summary Table:

| Feature | IGBT Advantage |

|---|---|

| Energy Efficiency | Low switching loss, minimal energy waste |

| Control & Precision | Exact power regulation for uniform heating |

| Melting Speed | Constant power output for faster cycles |

| Reliability | Advanced self-protection, reduced downtime |

| Harmonic Pollution | Very low, avoids grid interference |

Upgrade your melting process with KINTEK's advanced IGBT-powered induction furnaces.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Our IGBT-based induction melting systems deliver unmatched energy efficiency, precise temperature control, and faster melting cycles—ensuring higher productivity and superior melt quality for your operation.

Contact us today to discuss how our IGBT technology can optimize your melting process and reduce operational costs!

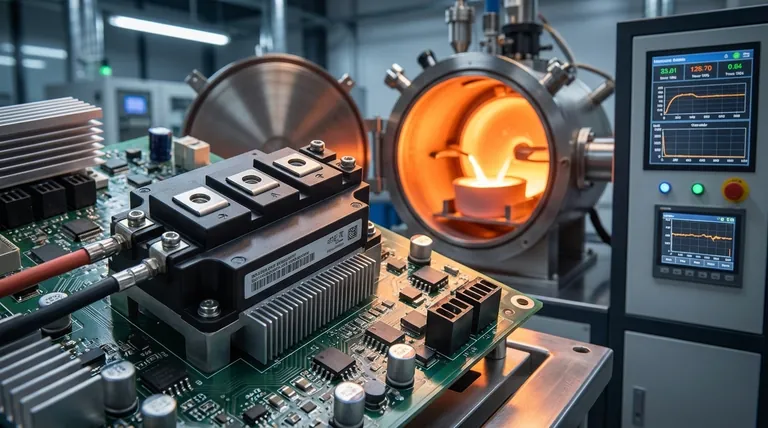

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity