In essence, High Density Plasma Chemical Vapor Deposition (HDP-CVD) is an advanced form of Plasma Enhanced Chemical Vapor Deposition (PECVD) that utilizes a highly concentrated, remotely generated plasma. Unlike conventional PECVD, where the plasma is typically created directly within the reaction chamber, HDP-CVD decouples plasma generation from the substrate. This separation provides independent control over the density of reactive species and the energy of ions bombarding the film, enabling unique and superior film properties.

The fundamental difference is one of control and intent. While all PECVD methods use plasma to deposit films at low temperatures, HDP-CVD is specifically engineered to create a much denser plasma that enables simultaneous deposition and sputtering, leading to superior film quality and gap-fill capabilities for demanding applications.

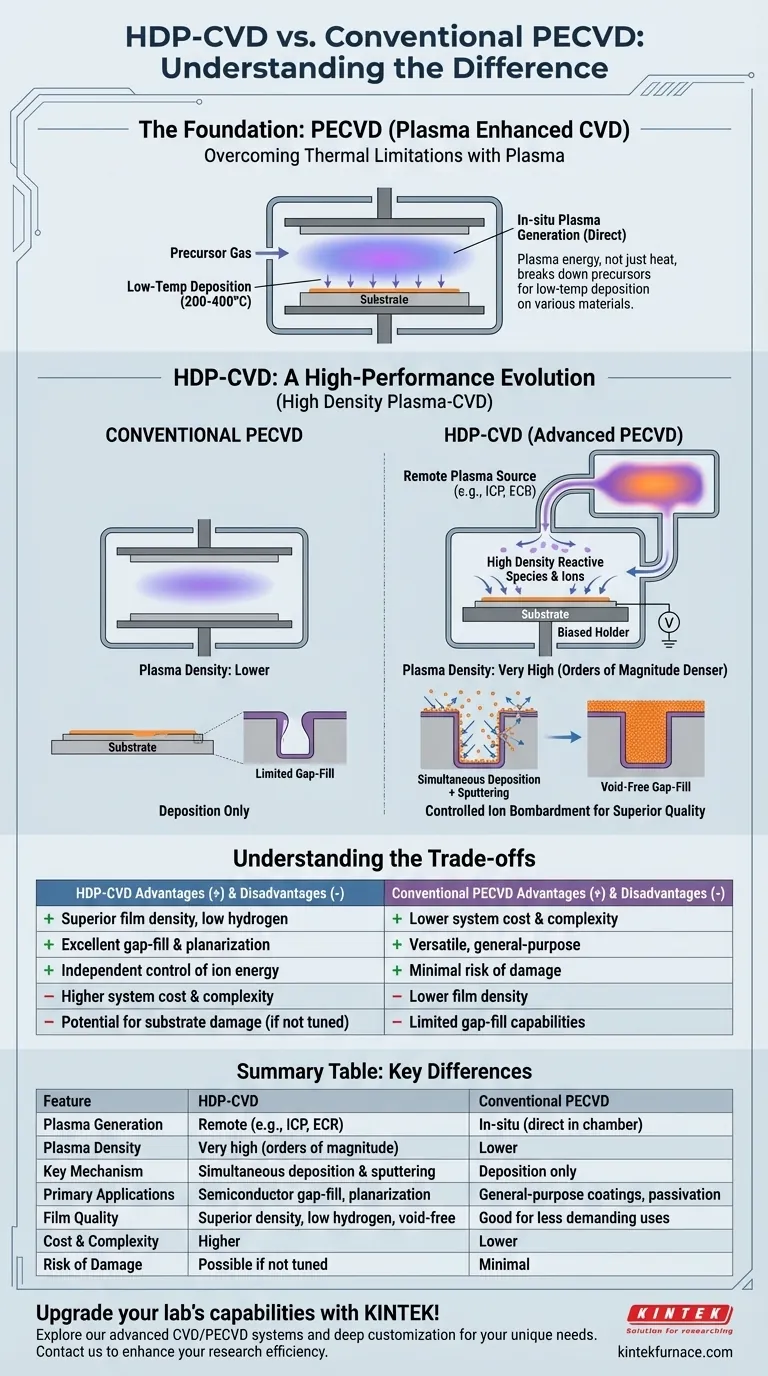

The Foundation: Understanding PECVD

To grasp the significance of HDP-CVD, we must first understand the principle behind all PECVD processes.

Overcoming Thermal Limitations

Traditional Chemical Vapor Deposition (CVD) relies on high temperatures to provide the thermal energy needed to break down precursor gases and drive chemical reactions on a substrate surface. This works well for robust materials but is unsuitable for temperature-sensitive substrates like plastics or complex semiconductor devices.

The Role of Plasma

PECVD overcomes this limitation by introducing energy in the form of plasma. Instead of relying solely on heat, energetic electrons within the plasma collide with and break apart the precursor gas molecules. This creates a high concentration of reactive chemical species at much lower temperatures (typically 200-400°C), allowing for high-quality film deposition on a wider variety of materials.

HDP-CVD: A High-Performance Evolution

HDP-CVD is not just an incremental improvement; it is a specialized evolution of PECVD designed for applications where film density and conformal coverage are critical.

Decoupling Plasma Generation

In a conventional PECVD system, the plasma is generated "in-situ," meaning directly between the electrodes where the substrate sits. In an HDP-CVD system, the plasma is generated remotely in a separate chamber, often using an Inductively Coupled Plasma (ICP) or Electron Cyclotron Resonance (ECR) source.

This dense plasma of reactive species and ions is then directed toward the substrate in the main chamber.

Achieving Uniquely High Plasma Density

The remote sources used in HDP-CVD are capable of generating a plasma that is orders of magnitude denser than in conventional PECVD. This high density of reactive species dramatically increases the efficiency of the deposition process.

The Deposition + Sputtering Mechanism

The most critical feature of HDP-CVD is the ability to apply an independent electrical bias to the substrate holder. This bias attracts the high concentration of ions from the plasma, causing them to bombard the substrate with controlled energy.

This controlled ion bombardment results in a simultaneous process of deposition (from the reactive neutrals) and sputtering (physical etching by the ions). This sputtering effect preferentially removes loosely deposited material from sharp corners, allowing for exceptionally dense, void-free filling of high-aspect-ratio gaps, such as trenches in semiconductor manufacturing.

Understanding the Trade-offs

Choosing HDP-CVD involves evaluating its powerful advantages against its inherent complexities.

Film Quality vs. Process Cost

HDP-CVD produces films with superior density, lower hydrogen content, and excellent gap-fill capabilities. However, the systems are significantly more complex and expensive than conventional PECVD reactors, both to purchase and to maintain.

Application Specificity vs. Generality

Because of its unique deposition/sputtering mechanism, HDP-CVD is the go-to process for demanding semiconductor gap-fill and planarization. Conventional PECVD is a more versatile, general-purpose tool suitable for a broader range of applications, such as passivation layers or simple coatings where gap-fill is not a concern.

Controlled Bombardment vs. Potential Damage

While HDP-CVD offers precise control over ion energy, the process is inherently based on ion bombardment. If not tuned correctly, this can induce damage in sensitive underlying device layers. Other remote PECVD techniques exist that use ion screening to ensure only neutral species reach the substrate, offering the lowest-damage process possible at the expense of HDP's gap-fill benefits.

Making the Right Choice for Your Goal

Your decision must be driven by the specific requirements of the film you need to create.

- If your primary focus is depositing high-quality, dense, and void-free films for advanced applications like semiconductor gap-fill: HDP-CVD is the superior choice due to its controlled ion bombardment and high-density plasma.

- If your primary focus is general-purpose film deposition, such as passivation layers on less complex or temperature-sensitive substrates where cost and throughput are key factors: Conventional PECVD offers a simpler, more cost-effective, and robust solution.

- If your primary focus is depositing a film with minimal to zero ion bombardment on an extremely sensitive electronic or optical device: A remote PECVD system specifically designed with ion screening would be the most appropriate method.

Ultimately, the choice between HDP-CVD and other PECVD methods hinges on a clear understanding of your required film properties and application demands.

Summary Table:

| Feature | HDP-CVD | Conventional PECVD |

|---|---|---|

| Plasma Generation | Remote (e.g., ICP, ECR) | In-situ (direct in chamber) |

| Plasma Density | Very high (orders of magnitude denser) | Lower |

| Key Mechanism | Simultaneous deposition and sputtering | Deposition only |

| Primary Applications | Semiconductor gap-fill, planarization | General-purpose coatings, passivation layers |

| Film Quality | Superior density, low hydrogen, void-free | Good for less demanding uses |

| Cost and Complexity | Higher | Lower |

| Risk of Substrate Damage | Possible if not tuned | Minimal |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with cutting-edge products like CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental needs, such as optimizing HDP-CVD processes for superior semiconductor applications. Contact us today to discuss how we can enhance your research and production efficiency!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision