In the context of dental furnaces, heating rate is the speed at which the furnace's internal temperature increases. This is measured in degrees Celsius per minute (°C/min) and is a critical, programmable setting that dictates how quickly a restoration is brought up to its final sintering temperature.

The heating rate is not merely a setting for cycle time; it is your primary tool for managing thermal stress. A slower, controlled heating rate is the key to preventing fractures and ensuring the final structural integrity and longevity of the restoration.

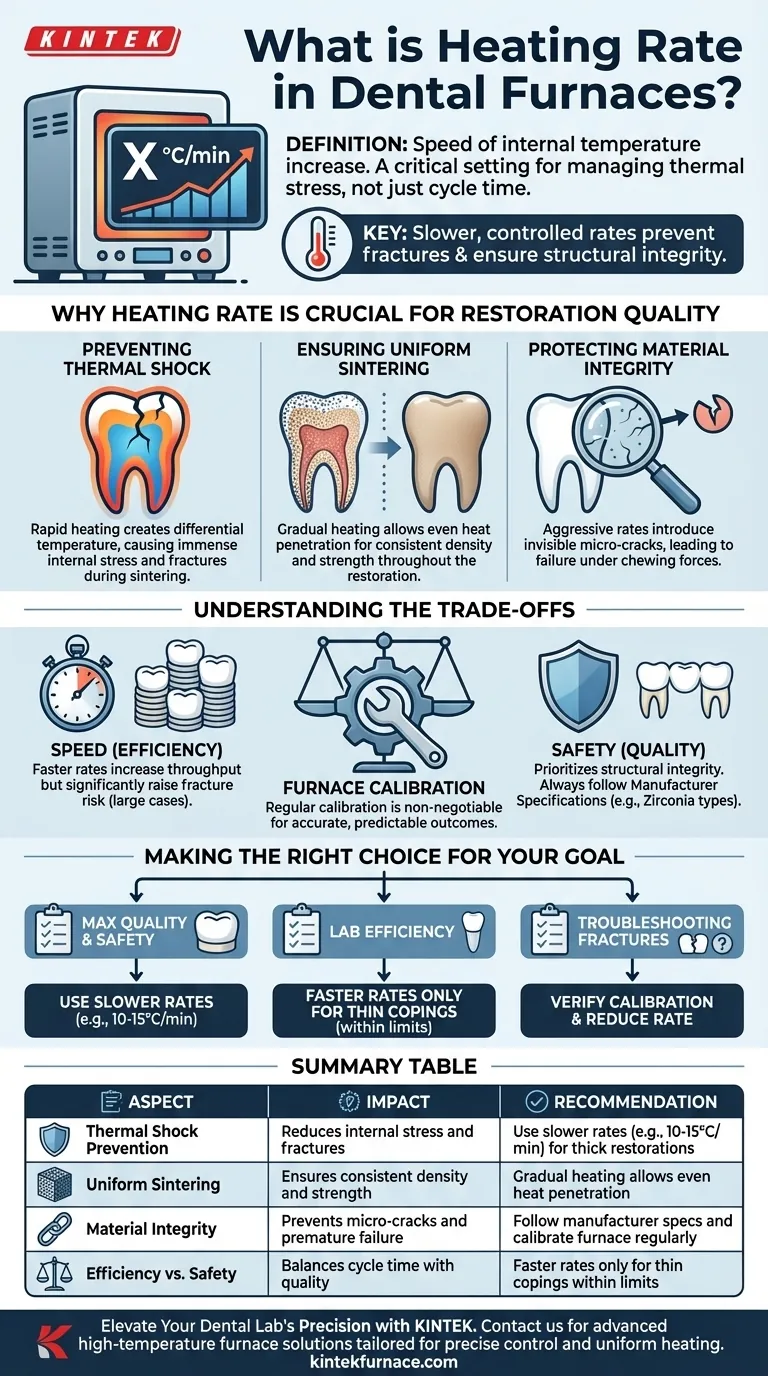

Why Heating Rate is Crucial for Restoration Quality

Understanding the heating rate moves you from simply operating a furnace to mastering the material science of dental ceramics. Its impact is direct and significant.

Preventing Thermal Shock

When a restoration is heated, the outer surface heats faster than the core. A rapid heating rate exaggerates this temperature difference.

This differential creates immense internal stress. This phenomenon, known as thermal shock, is the leading cause of fractures and micro-cracks in dental restorations during the sintering process.

Ensuring Uniform Sintering

Sintering is the process of densifying the ceramic to achieve its final strength. For this to happen correctly, the entire restoration must heat uniformly.

A gradual heating rate allows heat to penetrate the restoration evenly, especially in thicker areas like the cusps of a molar or the connectors of a bridge. This ensures consistent density and predictable strength throughout the entire piece.

Protecting Material Integrity

An aggressive heating rate can introduce microscopic flaws that are not visible to the naked eye. These micro-cracks become weak points in the final restoration.

Over time, these flaws can propagate under the stress of normal chewing forces, leading to premature failure of the crown or bridge in the patient's mouth.

Understanding the Trade-offs

Choosing a heating rate is a balance between efficiency and quality. There is no single setting that is perfect for every case.

Speed vs. Safety

A faster heating rate shortens the overall furnace cycle, which can increase a lab's daily throughput. This efficiency, however, comes at a high price.

The risk of fracture rises dramatically with faster rates. This is especially true for large-span bridges, full-arch restorations, or cases with significant variations in thickness.

Manufacturer Specifications

Different ceramic materials, such as various types of zirconia, have unique thermal properties. Always begin with the heating rate recommended by the material's manufacturer.

Their guidelines are based on extensive testing and represent the safest starting point for achieving the material's advertised physical and aesthetic properties.

The Critical Role of Furnace Calibration

Your set heating rate is meaningless if the furnace is not performing accurately. Regular calibration is non-negotiable for predictable outcomes.

An uncalibrated furnace can heat much faster or slower than the displayed rate, leading to inconsistent results, unexpected fractures, or incomplete sintering. This completely undermines any attempt to control the process.

Making the Right Choice for Your Goal

Use the heating rate as a deliberate tool to control your outcomes. Your choice should be based on the specific restoration and your primary objective.

- If your primary focus is maximum quality and safety: Always use a slower, more gradual heating rate (e.g., 10-15°C/min), especially for anatomically thick crowns, long-span bridges, or complex cases.

- If your primary focus is lab efficiency: Faster rates should only be considered for single, thin-walled copings and must never exceed the material manufacturer's maximum recommended value.

- If you are experiencing unexpected fractures: Immediately verify your furnace calibration is accurate and reduce your standard heating rate as the next troubleshooting step.

Mastering the heating rate transforms it from a simple machine setting into a powerful tool for achieving predictable, high-quality clinical outcomes.

Summary Table:

| Aspect | Impact | Recommendation |

|---|---|---|

| Thermal Shock Prevention | Reduces internal stress and fractures | Use slower rates (e.g., 10-15°C/min) for thick restorations |

| Uniform Sintering | Ensures consistent density and strength | Gradual heating allows even heat penetration |

| Material Integrity | Prevents micro-cracks and premature failure | Follow manufacturer specs and calibrate furnace regularly |

| Efficiency vs. Safety | Balances cycle time with quality | Faster rates only for thin copings within limits |

Elevate Your Dental Lab's Precision with KINTEK

Struggling with inconsistent heating rates or restoration failures? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to deliver precise temperature control and uniform heating. With strong deep customization capabilities, we can precisely meet your unique experimental requirements, ensuring flawless sintering and enhanced restoration quality.

Don't let thermal stress compromise your work—contact us today to discuss how our furnaces can optimize your processes and boost efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns