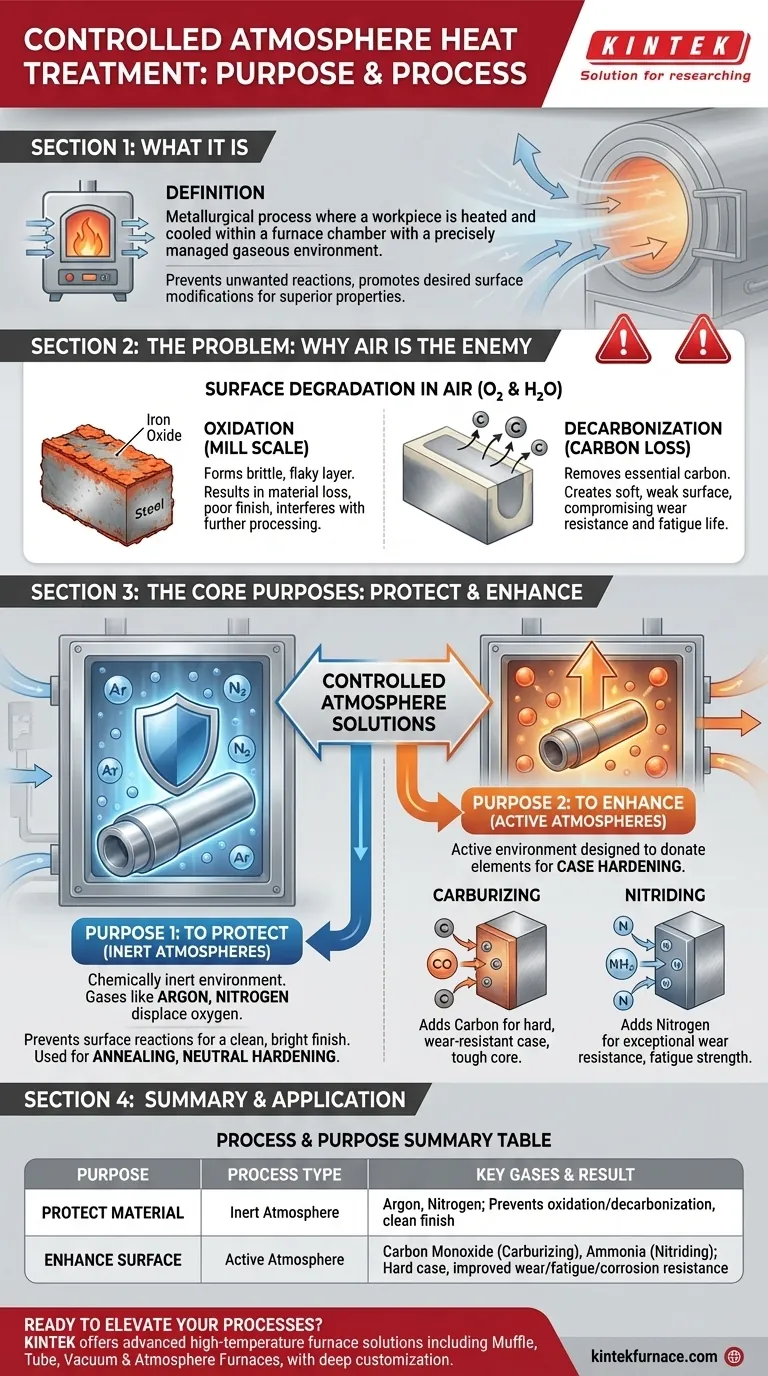

Controlled atmosphere heat treatment is a metallurgical process where a workpiece is heated and cooled within a furnace chamber containing a specifically managed gaseous environment. This precise control over the gas mixture is done to prevent unwanted chemical reactions, like oxidation, and to promote desired surface modifications, such as carburizing or nitriding, resulting in parts with superior mechanical properties.

The core purpose of controlled atmosphere heat treatment is to transform the furnace environment from a potential source of damage into a highly precise tool. It allows you to either perfectly preserve a material's existing surface chemistry or actively and predictably change it to meet specific engineering requirements.

The Fundamental Problem: Why Air is the Enemy

When steel is heated to high temperatures in normal air, the oxygen and moisture present become highly reactive. This leads to two primary forms of surface degradation that controlled atmospheres are designed to prevent.

The Threat of Oxidation

At elevated temperatures, oxygen readily reacts with the iron in steel to form a brittle, flaky layer of iron oxide, commonly known as mill scale. This process is not just a cosmetic issue; it results in material loss, a poor surface finish, and can interfere with subsequent processing steps like plating or coating.

The Risk of Decarbonization

In addition to adding oxygen, the atmosphere can also strip essential elements from the steel's surface. Decarbonization is the process where carbon atoms at the surface of the steel are removed by reacting with the furnace atmosphere. Since carbon is the primary element responsible for the hardness of steel, its loss creates a soft, weak surface layer that compromises the part's wear resistance and fatigue life.

The Core Purposes of a Controlled Atmosphere

By replacing air with a specific gas mixture, we gain the ability to dictate the chemical reactions that occur on the part's surface. This allows for two distinct objectives: protecting the material or enhancing it.

Purpose 1: To Protect (Inert Atmospheres)

The most basic function of a controlled atmosphere is to be chemically inert, meaning it will not react with the metal part. Gases like argon, nitrogen, or the dissociated products of ammonia are used to displace oxygen and moisture from the furnace.

This protective blanket is essential for processes like annealing (softening) or neutral hardening, where the goal is to change the material's microstructure without altering its surface chemistry. The result is a clean, bright part free from scale and decarbonization.

Purpose 2: To Enhance (Active Atmospheres)

More advanced applications use an active atmosphere, which is specifically designed to donate elements to the surface of the steel in a process known as case hardening.

Carburizing is a common example. A low-carbon steel part is heated in an atmosphere rich in a carbon-bearing gas, such as carbon monoxide. Carbon atoms diffuse into the surface, creating a part with a hard, wear-resistant outer case and a softer, tougher inner core.

Nitriding is another enhancement process. Parts are heated in an atmosphere containing a source of nitrogen, typically ammonia. Nitrogen atoms diffuse into the surface, forming extremely hard nitride compounds that provide exceptional wear resistance, fatigue strength, and some corrosion resistance.

Understanding the Trade-offs

While powerful, controlled atmosphere heat treatment is a more complex and costly process than heating in open air. Understanding its limitations is key to using it effectively.

Cost and Complexity

The furnaces are more complex, requiring sealed chambers, gas flow meters, and safety systems. The cost of the process gases and the sophisticated sensors needed to monitor the atmosphere's chemical potential add to the overall expense.

The Need for Precise Control

The process is unforgiving. A slight deviation in gas composition, temperature, or moisture content can ruin an entire batch of parts. This is why modern systems rely heavily on computer management and automated feedback loops to maintain the precise atmospheric conditions required for predictable, repeatable results.

Gas Selection is Critical

The choice of atmosphere is entirely dependent on the material being treated and the desired outcome. Using a carburizing atmosphere on a high-carbon tool steel, for example, would be a mistake, just as using a purely inert gas would fail to case harden a low-carbon steel part.

Matching the Process to Your Metallurgical Goal

Choosing the right atmospheric approach depends entirely on your final objective for the component.

- If your primary focus is preserving the bulk properties during annealing or stress relieving: Use a protective, inert atmosphere of nitrogen or argon to prevent surface damage.

- If your primary focus is creating a hard, wear-resistant surface on a ductile, low-carbon steel: Use an active carburizing atmosphere to add a high-carbon case.

- If your primary focus is achieving extreme surface hardness and improved fatigue life on alloy steels: Use an active nitriding atmosphere to form a hard nitride layer.

Ultimately, mastering controlled atmosphere treatment transforms the process from simple heating into a precise and powerful method of surface engineering.

Summary Table:

| Purpose | Process Type | Key Gases Used | Result |

|---|---|---|---|

| Protect Material | Inert Atmosphere | Argon, Nitrogen | Prevents oxidation and decarbonization; clean, bright finish |

| Enhance Surface | Active Atmosphere | Carbon Monoxide (Carburizing), Ammonia (Nitriding) | Hard, wear-resistant case; improved fatigue and corrosion resistance |

Ready to elevate your metallurgical processes with precise heat treatment solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior results in controlled atmosphere heat treatment!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity