In essence, Chemical Vapor Deposition (CVD) is a highly controlled manufacturing process used to create high-purity, solid materials, typically as a thin film or coating on a surface. It works by introducing precursor gases into a chamber where they react and decompose upon contact with a heated object (the substrate), leaving behind a layer of the desired material. This method is fundamental to producing everything from computer chips to corrosion-resistant coatings.

Chemical Vapor Deposition is not simply a coating method; it is a foundational "bottom-up" fabrication technique. By building a material atom-by-atom from a gas phase, CVD achieves a level of purity, control, and uniformity that is often impossible with conventional methods.

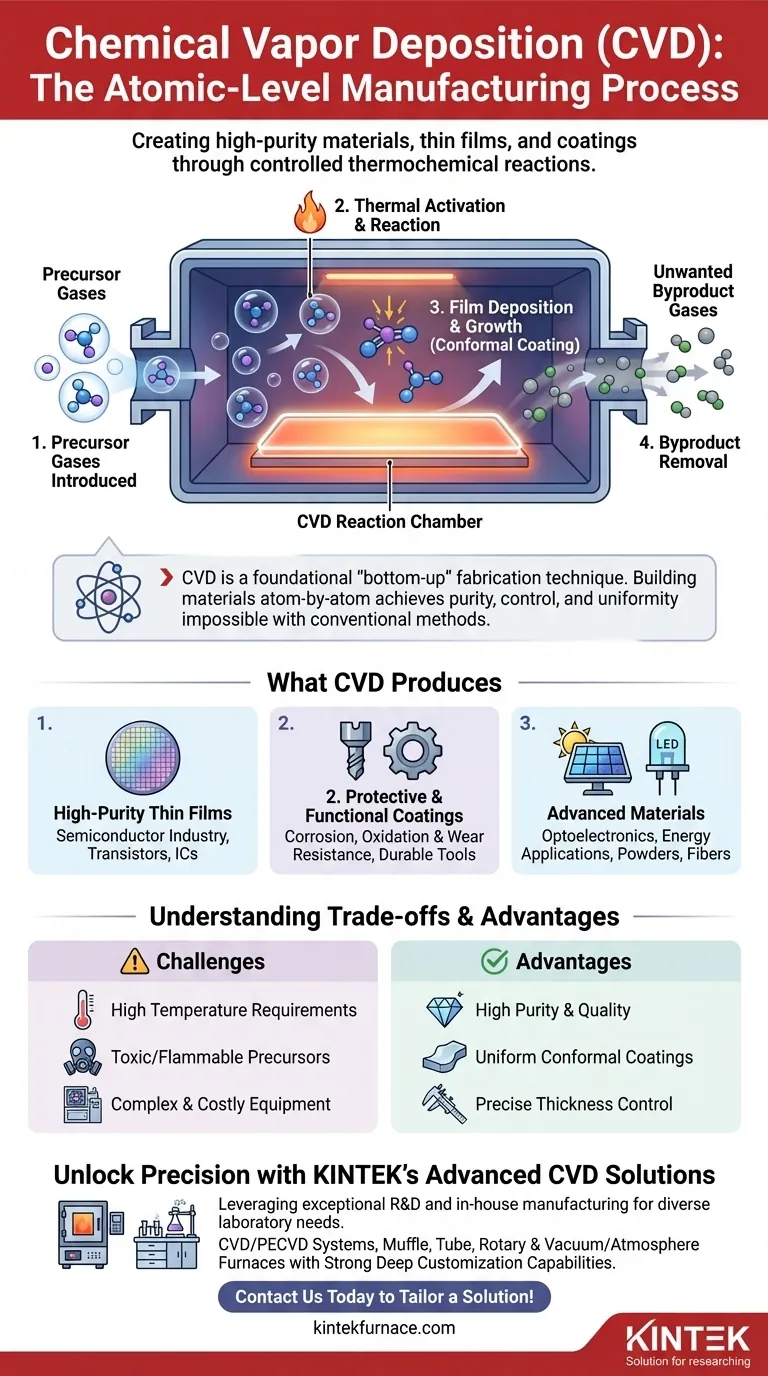

How Chemical Vapor Deposition Works: The Core Process

CVD is a thermochemical process that can be broken down into a few key steps. Understanding this sequence reveals why the technique is so powerful and versatile.

Step 1: Introducing Precursor Gases

The process begins by feeding specific, carefully measured gases, known as precursors, into a reaction chamber. These gases contain the chemical elements that will ultimately form the final solid film.

The chamber's environment, including pressure (which can range from atmospheric to a high vacuum) and temperature, is precisely controlled.

Step 2: Activating the Chemical Reaction

The substrate—the object to be coated—is heated inside the chamber. When the precursor gases come into contact with the hot surface, the thermal energy triggers a chemical reaction.

This energy causes the precursor molecules to decompose or react with each other. The result is the formation of the desired solid material and other gaseous byproducts. Some advanced CVD methods use plasma instead of just heat to drive this reaction at lower temperatures.

Step 3: Deposition and Film Growth

The newly formed solid material deposits onto the substrate, creating a thin, solid film. This deposition occurs across all exposed surfaces of the object, resulting in what is known as a conformal coating that uniformly covers even complex shapes.

The thickness of this film is precisely controlled by managing the deposition time and the concentration of the precursor gases.

Step 4: Removing Byproducts

As the deposition occurs, the unwanted gaseous byproducts from the chemical reaction are continuously pumped out of the chamber, ensuring the purity of the growing film.

What Does CVD Produce?

The output of a CVD process is an exceptionally high-quality solid material. While most commonly associated with thin films, its applications are diverse.

High-Purity Thin Films

This is the primary product of CVD. These films are the bedrock of the semiconductor industry, used to create the layered structures of transistors and integrated circuits on silicon wafers.

Protective and Functional Coatings

CVD is used to apply extremely hard and durable coatings to tools, mechanical parts, and other components. These coatings provide powerful resistance to corrosion, oxidation, and wear, dramatically extending the life and performance of the underlying material.

Advanced Materials

The process can also produce powders, fibers, and even complete, free-standing monolithic parts. It is essential for creating materials for optoelectronics (like LEDs) and energy applications, including printable solar cells.

Understanding the Trade-offs

While powerful, CVD is not without its challenges. A true understanding requires acknowledging its operational demands.

High Temperature Requirements

Traditional CVD processes often require very high temperatures to activate the chemical reactions. This can limit the types of substrate materials that can be used, as some may deform or be damaged by the heat.

Precursor and Byproduct Handling

The precursor gases used in CVD can be toxic, flammable, or corrosive. This necessitates sophisticated safety protocols and handling systems. Similarly, the waste byproducts must be managed and treated properly.

Equipment Complexity

Achieving the necessary vacuum conditions and precise temperature control requires complex and often expensive equipment, making the initial investment for CVD systems significant.

Making the Right Choice for Your Goal

The value of CVD is best understood through the lens of its industrial application.

- If your primary focus is electronics and microfabrication: CVD is the non-negotiable standard for creating the ultra-pure, uniform, and crystalline thin films required for modern semiconductors.

- If your primary focus is mechanical durability: CVD provides superior protective coatings that enhance the life and performance of tools and components against harsh operational conditions.

- If your primary focus is next-generation materials: CVD is a key enabling technology for research and development in energy, optics, and catalysis, allowing for the creation of novel materials with precisely engineered properties.

Ultimately, Chemical Vapor Deposition is a cornerstone of modern technology, enabling us to build advanced materials with atomic-level precision.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Thermochemical reaction of precursor gases on a heated substrate to deposit solid materials. |

| Key Products | High-purity thin films, protective coatings, powders, fibers, and monolithic parts. |

| Main Applications | Semiconductors, corrosion-resistant coatings, optoelectronics, and energy technologies. |

| Advantages | High purity, uniform conformal coatings, precise control over film thickness. |

| Challenges | High temperatures, handling of toxic precursors, complex and costly equipment. |

Unlock Precision in Your Laboratory with KINTEK's Advanced CVD Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line includes CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you're developing semiconductors, enhancing material durability, or pioneering next-generation energy applications, our CVD systems deliver the atomic-level precision and reliability you need. Contact us today to discuss how we can tailor a solution for your specific goals and drive your innovations forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment