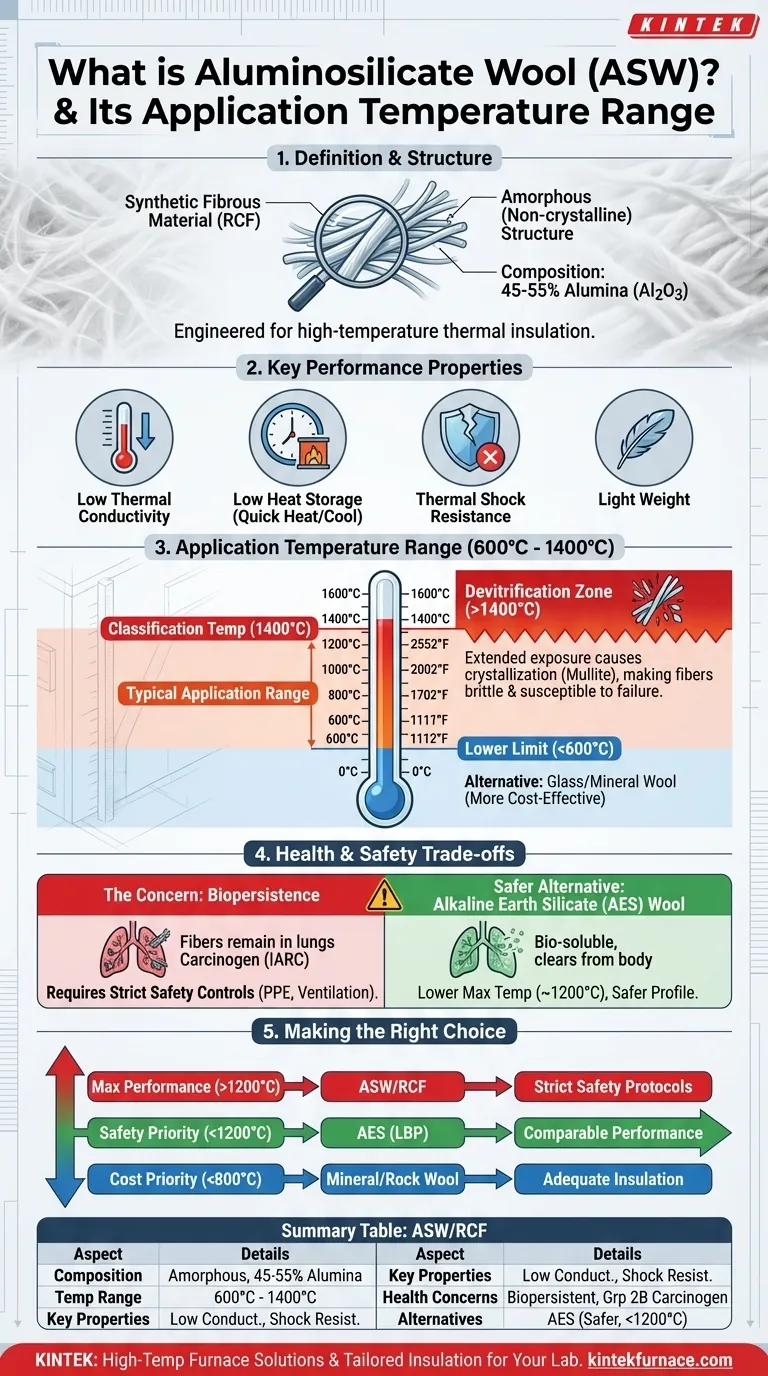

In high-temperature industrial environments, aluminosilicate wool (ASW) is a synthetic fibrous material engineered for thermal insulation and fire protection. Also known as refractory ceramic fiber (RCF), it is defined by its composition of amorphous (non-crystalline) fibers containing 45% to 55% alumina (Al2O3). Its typical application temperature range is between 600°C and 1400°C (1112°F to 2552°F).

ASW, or Refractory Ceramic Fiber (RCF), is a highly effective insulation material for extreme heat due to its low thermal conductivity. However, its use is governed by significant health and safety considerations, which has driven the development of safer, low biopersistent alternatives for many applications.

What Defines Aluminosilicate Wool?

Understanding ASW begins with its fundamental composition and structure, which directly determine its performance characteristics in extreme environments.

Core Composition and Structure

ASW consists of long, flexible fibers produced by melting and spinning or blowing a mixture of high-purity alumina and silica. The resulting material is an amorphous, glass-like structure, which is key to its low thermal conductivity. Unlike crystalline materials, this random structure is highly effective at scattering phonons, the primary carriers of heat in solids.

Key Performance Properties

The unique structure of ASW gives it several critical properties for high-temperature applications:

- Low Thermal Conductivity: It is an exceptional insulator, drastically reducing heat transfer.

- Low Heat Storage: It heats up and cools down quickly, improving the efficiency of cyclic furnaces and kilns.

- Excellent Thermal Shock Resistance: It can withstand rapid temperature changes without cracking or degrading.

- Light Weight: Its low density makes it easy to install and reduces the structural load on equipment.

The "RCF" Designation

The terms Aluminosilicate Wool (ASW) and Refractory Ceramic Fiber (RCF) are often used interchangeably. RCF is a broader regulatory and industry term, but for materials in the 45-55% alumina range, it almost always refers to ASW.

Understanding the Application Temperature Range

The specified temperature range of 600°C to 1400°C is not arbitrary; it reflects the material's operational limits and optimal use cases.

The 600°C Lower Limit

While ASW can function at lower temperatures, it is often technically and financially excessive. Materials like glass wool or mineral wool provide adequate insulation at a lower cost for applications below approximately 600°C.

The 1400°C Upper Limit

This value represents the material's classification temperature. It is the maximum continuous temperature the wool can withstand before significant physical and chemical changes begin to degrade its performance. It is not a melting point, which is typically much higher.

The Impact of Devitrification

When ASW is exposed to temperatures near or above its classification limit for extended periods, it undergoes a process called devitrification. The amorphous fibers begin to convert into a crystalline state (mullite and cristobalite). This crystallization makes the fibers brittle, causing the material to shrink, lose its insulating properties, and become susceptible to mechanical failure.

Understanding the Trade-offs and Health Concerns

The high performance of ASW comes with a critical trade-off: its potential health risks. This is the single most important factor to consider when specifying this material.

The Primary Concern: Biopersistence

ASW/RCF fibers are biopersistent, meaning that if inhaled, they can remain in the lung tissue for a long time. The body has difficulty clearing them, which can lead to chronic inflammation and other serious health issues.

Regulatory Classification

Due to its biopersistence, the International Agency for Research on Cancer (IARC) classifies RCF as a Group 2B carcinogen, meaning it is "possibly carcinogenic to humans." This classification mandates strict workplace safety controls, including respiratory protection, specialized ventilation, and handling procedures.

The Rise of Low Biopersistent (LBP) Fibers

To address these health concerns, the industry developed Alkaline Earth Silicate (AES) wool. Also known as high-temperature bio-soluble fibers, AES fibers are designed to be dissolved and cleared by bodily fluids if inhaled. While their maximum service temperature is typically lower than the highest grades of ASW (around 1200°C), they offer a much safer profile for workers and are now the preferred choice in many applications.

Making the Right Choice for Your Application

Selecting the correct high-temperature insulation requires a clear understanding of your project's priorities.

- If your primary focus is maximum thermal performance up to 1400°C: ASW/RCF remains a benchmark standard, but you must implement rigorous engineering controls and personal protective equipment (PPE) protocols.

- If your primary focus is safety and regulatory compliance: Prioritize Alkaline Earth Silicate (AES) or other low biopersistent (LBP) fibers, especially for applications below 1200°C where their performance is comparable.

- If your primary focus is cost-effectiveness below 800°C: Consider traditional insulation like mineral wool or rock wool, as ASW/RCF would be an unnecessary expense and hazard.

Ultimately, selecting the right high-temperature insulation requires balancing thermal requirements against critical health, safety, and regulatory obligations.

Summary Table:

| Aspect | Details |

|---|---|

| Composition | Amorphous fibers with 45-55% alumina (Al2O3) |

| Application Temperature Range | 600°C to 1400°C (1112°F to 2552°F) |

| Key Properties | Low thermal conductivity, low heat storage, excellent thermal shock resistance, lightweight |

| Health Concerns | Biopersistent fibers, classified as Group 2B carcinogen by IARC |

| Alternatives | Alkaline Earth Silicate (AES) wool for safer options up to 1200°C |

Need reliable high-temperature furnace solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs. Contact us today to enhance your lab's efficiency and safety with tailored insulation solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals