At its core, a Vacuum Induction Melting (VIM) furnace is a highly specialized system for producing exceptionally pure metals and alloys. It combines two key technologies: medium-frequency induction heating to melt the material and a high-vacuum chamber to isolate it from atmospheric contamination. This dual approach allows for a level of compositional precision and cleanliness that is unattainable with conventional air-melting furnaces.

A VIM furnace is not just for melting metal; it is a refining tool. Its primary purpose is to eliminate environmental variables—specifically oxygen and nitrogen—to create materials with precisely controlled chemistry and superior mechanical properties.

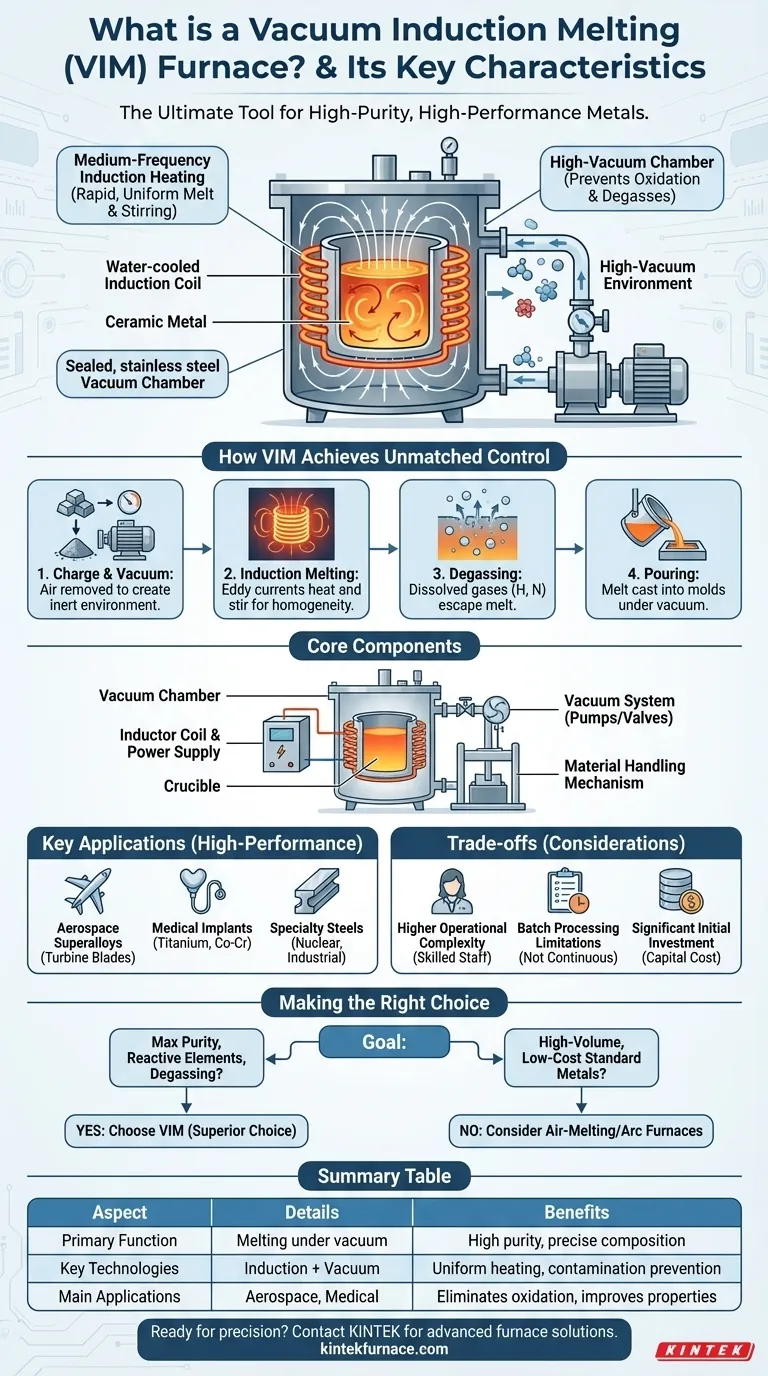

How a VIM Furnace Achieves Unmatched Control

The power of the VIM process lies in how it fundamentally changes the melting environment. By removing the atmosphere, it removes the primary source of impurities and unwanted chemical reactions.

The Principle of Induction Heating

An alternating electrical current is passed through a water-cooled copper coil, known as an inductor. This creates a powerful, fluctuating magnetic field around the raw metal (charge) held within a crucible.

This magnetic field induces strong electrical eddy currents directly within the metal itself, causing it to heat rapidly and uniformly from the inside out. This process also creates a natural stirring effect, ensuring the molten metal becomes completely homogenized.

The Critical Role of the Vacuum

The entire process occurs within a sealed, robust chamber from which nearly all air has been removed by a powerful vacuum system.

Operating under vacuum provides two distinct advantages. First, it prevents oxidation by removing oxygen, which is critical when working with reactive metals like titanium or superalloys containing aluminum. Second, the low-pressure environment facilitates the removal of dissolved gases like hydrogen and nitrogen from the melt, a process known as degassing.

Core Components and Their Function

A VIM system is an integration of several critical subsystems:

- Vacuum Chamber: The sealed steel vessel that contains the melt and maintains the vacuum.

- Inductor Coil & Power Supply: Generates the magnetic field responsible for heating and stirring the metal.

- Crucible: A ceramic or graphite container that holds the charge material and can withstand extreme temperatures.

- Vacuum System: A network of pumps, valves, and gauges responsible for creating and monitoring the low-pressure environment.

- Material Handling: Internal mechanisms for charging raw materials and tilting the crucible to pour the finished melt into a mold, all without breaking the vacuum.

Key Capabilities and Applications

The unique characteristics of the VIM process make it essential for manufacturing the most demanding materials used in modern technology.

Precision Alloying and Composition Control

With the risk of oxidation eliminated, metallurgists can introduce highly reactive alloying elements with extreme accuracy. This allows for the production of alloys with tight compositional tolerances that meet exacting specifications for aerospace, medical, or nuclear applications.

Refining High-Performance Materials

VIM is the standard for producing nickel-based superalloys, specialty steels, and other high-temperature materials used in jet engine turbine blades and industrial gas turbines. It is also used for medical-grade cobalt-chrome and titanium alloys for implants.

Degassing for Superior Mechanical Properties

Removing dissolved gases like hydrogen is crucial for preventing material defects. Hydrogen embrittlement, for example, can cause catastrophic failure in high-strength components. VIM processing significantly enhances a material's fatigue life, ductility, and overall reliability.

Understanding the Trade-offs

While powerful, the VIM process is not a universal solution. Its specialization comes with specific operational considerations.

Higher Operational Complexity

Operating a VIM furnace requires highly skilled personnel. Managing the interplay between the high-power electrical system, the high-vacuum system, and the high-temperature molten metal demands significant training and expertise.

Batch Processing Limitations

VIM is inherently a batch process. Each melt, from charging and pump-down to melting and pouring, is a discrete cycle. This makes it less suitable for the kind of high-volume, continuous production associated with commodity metals.

Significant Initial Investment

VIM furnaces are sophisticated, complex systems that represent a major capital investment. The infrastructure required for the power supply, water cooling, and vacuum systems adds to the overall cost, making it an investment justified only for high-value materials.

Making the Right Choice for Your Goal

Selecting a melting process depends entirely on the required purity and performance of the final product.

- If your primary focus is maximum purity and precise control of reactive elements: VIM is the necessary and superior choice for creating superalloys or medical-grade metals.

- If your primary focus is removing dissolved gases to improve mechanical properties: The vacuum environment of a VIM furnace is unmatched for effective degassing.

- If your primary focus is high-volume, low-cost production of standard metals: A VIM furnace is overkill; conventional air-melting or arc furnaces are far more economical.

Ultimately, choosing a VIM furnace is a strategic decision to prioritize material quality and performance above all else.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Melting and refining metals under vacuum for high purity and precise composition control |

| Key Technologies | Induction heating for uniform melting and stirring; vacuum chamber for contamination prevention |

| Main Applications | Aerospace superalloys, medical implants, specialty steels, nuclear materials |

| Key Benefits | Elimination of oxidation, degassing for improved mechanical properties, tight compositional tolerances |

| Considerations | High operational complexity, batch processing, significant initial investment |

Ready to elevate your metal production with precision and purity? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces, as well as CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're working with reactive metals, superalloys, or medical-grade materials. Don't let impurities hold you back—contact us today to discuss how our VIM furnaces and other solutions can enhance your lab's efficiency and product quality!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys