At its core, a vacuum furnace is a highly specialized piece of equipment that heats materials inside a chamber from which the air has been removed. This vacuum environment is the key to its function, as it prevents chemical reactions like oxidation and eliminates sources of contamination, allowing for the processing of materials at extremely high temperatures with unparalleled purity and control.

The fundamental purpose of a vacuum furnace is not just to heat materials, but to control their environment completely. By removing air and other gases, it enables thermal processes that would be impossible in a standard atmosphere, resulting in materials with superior strength, purity, and performance.

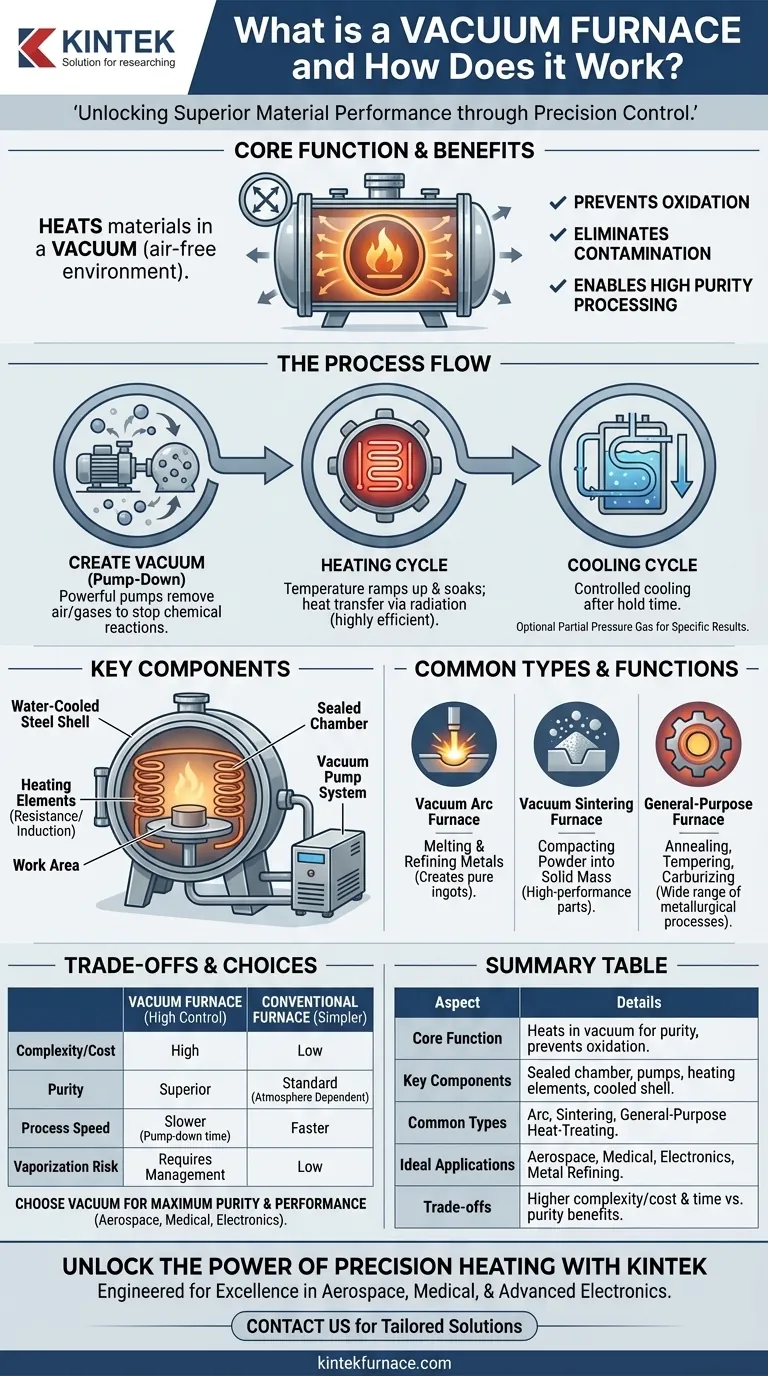

How a Vacuum Furnace Achieves Its Goal

A vacuum furnace's operation is a sequence of carefully controlled steps designed to create a pure, high-heat environment. It is fundamentally different from a conventional furnace that heats materials in the open air.

The Principle of the Vacuum

The first and most critical step is creating the vacuum. A powerful pump system removes air and other gases from a sealed chamber. This achieves two primary objectives:

- Prevents Oxidation: With no oxygen present, materials can be heated to very high temperatures without burning, scaling, or oxidizing.

- Eliminates Contamination: The vacuum removes airborne impurities that could otherwise compromise the material's integrity.

Core Components and Construction

A vacuum furnace is built around a few key components. The main body, or shell, is typically welded from steel and is often water-cooled to maintain its structural integrity under extreme heat. Inside this shell is a work area where the material is placed.

The entire system is sealed to be airtight. The heating elements, which generate the high temperatures, are located inside this sealed chamber. These elements can operate via electrical resistance or magnetic induction, depending on the furnace type.

The Heating and Cooling Cycle

Only after a stable vacuum has been achieved does the heating cycle begin. The temperature is precisely ramped up to the target, held for a specific duration (a "soak"), and then cooled down.

Because a vacuum eliminates heat transfer through convection (air movement), the process is highly efficient. Some furnaces also allow for the introduction of a specific gas at low pressure (partial pressure) to achieve specific results, such as preventing the vaporization of certain elements like chromium in steel.

Common Types and Their Functions

While all vacuum furnaces share the same core principle, they are often specialized for different industrial processes.

Vacuum Arc Furnace

This type is used for melting and refining metals. It uses a high-power electric arc to melt a raw metal electrode inside the vacuum chamber. The vacuum environment ensures the resulting ingot is free from gas-related impurities.

Vacuum Sintering Furnace

Sintering is the process of compacting and forming a solid mass of material from powder using heat. A vacuum sintering furnace often uses induction heating to fuse metallic or ceramic powders into a dense, high-performance part without melting them completely.

General-Purpose Heat-Treating Furnace

These versatile furnaces are used for a wide range of common metallurgical processes. This includes annealing (softening metal), tempering (increasing toughness), and vacuum carburizing (hardening the surface of steel), all performed without the risk of surface oxidation.

Understanding the Trade-offs

A vacuum furnace offers immense control, but that control comes with inherent trade-offs compared to simpler, atmospheric furnaces like a muffle furnace.

Complexity vs. Simplicity

A muffle furnace simply heats a chamber to a high temperature in the presence of air. It is simple, robust, and effective for processes where atmospheric reaction is not a concern. A vacuum furnace is a far more complex system, requiring vacuum pumps, robust seals, and sophisticated controls, which increases cost and maintenance.

Purity vs. Speed

Creating a deep vacuum takes time. The "pump-down" phase adds to the total cycle time of any process. If your primary goal is simply to heat a material quickly and purity is a secondary concern, a conventional furnace is much faster.

Precision Control vs. Potential Vaporization

The low-pressure environment can cause certain elements within an alloy to "boil off" or vaporize at high temperatures. This requires careful management, often through the use of partial pressure control, adding another layer of operational complexity.

Making the Right Choice for Your Process

Choosing the correct furnace technology depends entirely on the desired outcome for your material.

- If your primary focus is maximum material purity and performance: A vacuum furnace is non-negotiable for applications like aerospace components, medical implants, or advanced electronics.

- If your primary focus is simple heating with no strict atmospheric requirements: A conventional muffle or convection furnace is a more practical and cost-effective solution.

- If your primary focus is melting and refining raw metals into ultra-clean ingots: A specialized vacuum arc furnace is the correct tool for the job.

- If your primary focus is creating dense parts from metal or ceramic powders: A vacuum sintering furnace provides the necessary control for superior results.

Ultimately, a vacuum furnace is the definitive tool when the integrity of the material's environment is just as important as the temperature it is exposed to.

Summary Table:

| Aspect | Details |

|---|---|

| Core Function | Heats materials in a vacuum to prevent oxidation and contamination, enabling high-purity thermal processing. |

| Key Components | Sealed chamber, vacuum pump system, heating elements (electrical resistance or induction), water-cooled shell. |

| Common Types | Vacuum Arc Furnace (melting metals), Vacuum Sintering Furnace (forming parts from powder), General-Purpose Heat-Treating Furnace (annealing, tempering, carburizing). |

| Ideal Applications | Aerospace components, medical implants, advanced electronics, metal refining, and ceramic part fabrication. |

| Trade-offs | Higher complexity and cost vs. conventional furnaces; slower pump-down times; requires careful vaporization management. |

Unlock the Power of Precision Heating with KINTEK

Are you working in aerospace, medical device manufacturing, or advanced electronics and need flawless material processing? KINTEK's advanced high-temperature furnace solutions are engineered for excellence. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Don't let contamination or oxidation compromise your results. Contact us today to discuss how our tailored vacuum furnace solutions can enhance your material purity, boost performance, and drive innovation in your lab!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement