At its core, a rotary tube sintering furnace is specialized heat treatment equipment designed to achieve superior uniformity when processing powders and granular materials. It uniquely combines the continuous tumbling action of a rotary system with the controlled atmosphere and precise heating of a tube furnace, ensuring every particle undergoes the same thermal cycle.

The fundamental advantage of a rotary tube furnace is its ability to dynamically mix materials during heating. This prevents agglomeration and eliminates hot spots, delivering a level of process consistency that static furnaces cannot match for particulate matter.

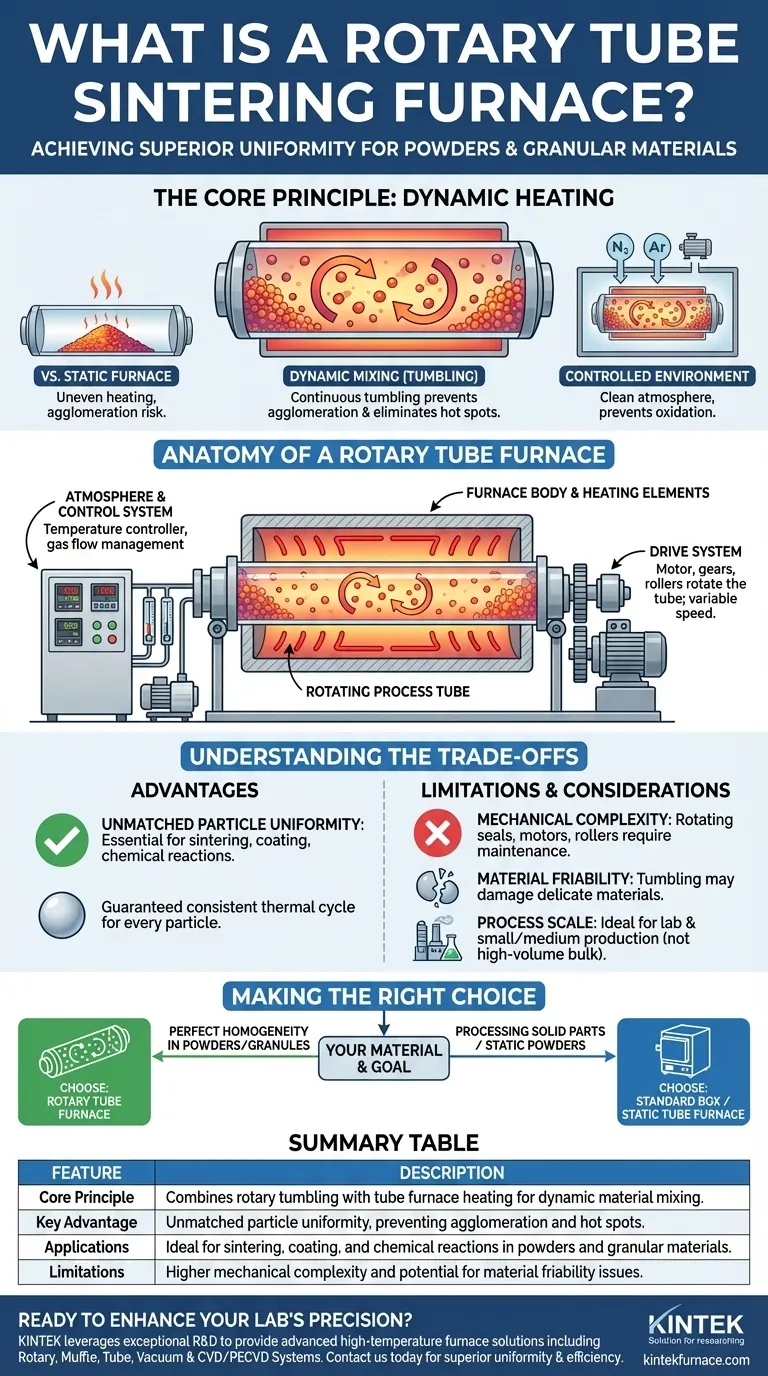

The Core Principle: Dynamic Heating in a Controlled Environment

Unlike a standard furnace where materials sit motionless, a rotary tube furnace actively tumbles the material. This simple mechanical action is the key to its effectiveness in specific applications.

The Rotation Mechanism

An external motor and drive system slowly rotate the central process tube along its horizontal axis. This causes the granular or powdered material inside to cascade, continuously exposing new surfaces to the heat source and the process atmosphere. The rotation speed is often variable, allowing for precise control over the mixing intensity.

The Tube Furnace Design

The entire process occurs within an enclosed tube, which is the defining characteristic of a "tube furnace." This enclosure is critical for maintaining a clean, controlled atmosphere. It allows for processing in a vacuum or with specific gases like nitrogen or argon to prevent oxidation, or with reactive gases for chemical synthesis.

Precision Temperature Control

Heating is typically indirect, meaning the heating elements warm the outside of the tube, which in turn radiates heat to the material. Thermocouples monitor the temperature, feeding data to a controller that adjusts power to the heating elements. Advanced systems feature multiple independent heating zones along the tube's length, enabling highly customized and precise temperature profiles for different stages of a process.

Anatomy of a Rotary Tube Furnace

The design integrates four primary systems to achieve its function.

The Rotating Process Tube

This is the heart of the furnace. It contains the material and the process atmosphere. The tube itself is typically made of quartz for lower temperatures or a ceramic like alumina for high-temperature applications, chosen for thermal stability and chemical inertness.

The Furnace Body & Heating Elements

This is the insulated outer casing that houses the process tube and the heating elements (either resistive wires or silicon carbide rods). The insulation ensures thermal efficiency and a safe external temperature, while the elements provide the energy for the process.

The Drive System

This system consists of a motor, gears, and rollers that support and rotate the process tube. A reliable drive with variable speed control is essential for adapting the process to different materials and desired outcomes.

The Atmosphere & Control System

This includes the temperature controller, gas flow meters, and vacuum pumps. This electronic brain of the furnace executes the programmed temperature profile and manages the gas environment inside the tube, ensuring the process is repeatable and accurate.

Understanding the Trade-offs

While powerful, a rotary tube furnace is not a universal solution. Understanding its specific strengths and weaknesses is key to proper application.

Advantage: Unmatched Particle Uniformity

The primary reason to select this technology is for heat treating powders, granules, or small parts where absolute uniformity is critical. The tumbling action guarantees that every particle experiences the same conditions, which is essential for sintering, coating, and chemical reactions.

Limitation: Mechanical Complexity

The need for rotating seals, drive motors, and roller supports adds mechanical complexity compared to a simple, static tube or box furnace. These components require maintenance and represent potential points of failure that do not exist in simpler designs.

Consideration: Material Friability

The tumbling action, while beneficial for mixing, can be detrimental to delicate or friable materials. The mechanical stress can cause particles to break down or abrade, which may be undesirable depending on the application.

Consideration: Process Scale

Rotary tube furnaces are ideal for laboratory-scale research and specialized, small-to-medium-scale production. For extremely high-volume industrial processes, such as cement manufacturing, a much larger piece of equipment called a rotary kiln is used. While based on a similar principle, a kiln operates on a vastly different scale.

Making the Right Choice for Your Process

Your choice of furnace should be dictated entirely by the physical nature of your material and your final process goal.

- If your primary focus is perfect homogeneity in powders or granules: A rotary tube furnace is the ideal tool for achieving consistent particle-to-particle heat treatment.

- If your primary focus is simplicity for processing solid parts or static powders: A standard box furnace or static tube furnace offers a simpler, more cost-effective solution.

- If your primary focus is extremely high-volume bulk material processing: You require a large-scale industrial rotary kiln, not a specialized rotary tube furnace.

Ultimately, a rotary tube furnace is a precision instrument for solving the specific challenge of uniformly heating dynamic materials in a controlled environment.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Combines rotary tumbling with tube furnace heating for dynamic material mixing. |

| Key Advantage | Unmatched particle uniformity, preventing agglomeration and hot spots. |

| Applications | Ideal for sintering, coating, and chemical reactions in powders and granular materials. |

| Limitations | Higher mechanical complexity and potential for material friability issues. |

Ready to enhance your lab's precision in powder processing? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our rotary tube sintering furnaces can deliver superior uniformity and efficiency for your materials!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What level of process control do rotary tube furnaces provide? Achieve Precise Thermal Processing for Uniform Results

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- What optional features enhance the processing capabilities of rotary tube furnaces? Boost Efficiency with Advanced Customizations

- In what environments are rotary tube furnaces considered indispensable? Essential for Uniform Thermal Processing