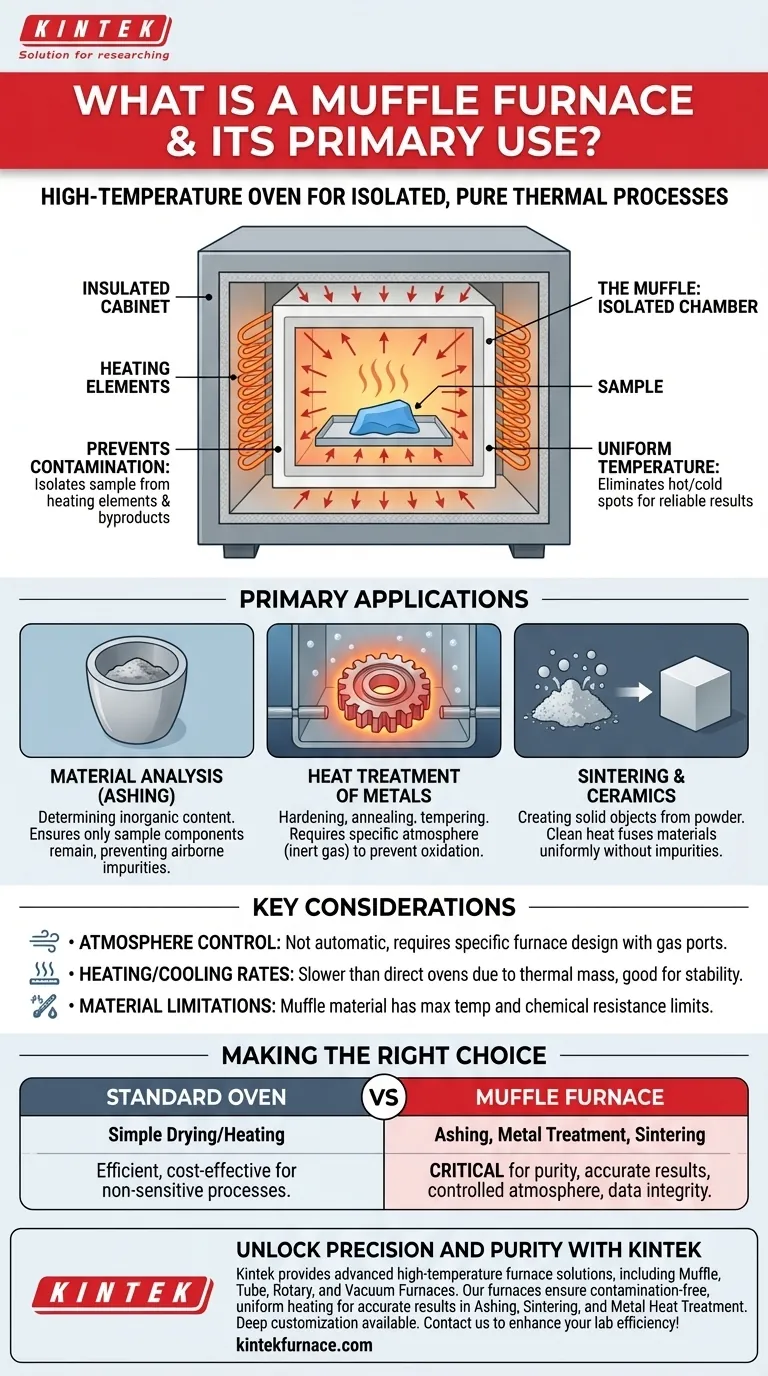

At its core, a muffle furnace is a high-temperature oven that excels at one critical task: heating materials within a chamber that is completely isolated from the heating elements and outside contaminants. Its primary function is to perform thermal processes like ashing, sintering, and heat-treating metals where sample purity and a controlled environment are non-negotiable.

The true value of a muffle furnace isn't just its ability to reach high temperatures. Its defining feature is the "muffle"—an internal chamber that isolates the sample, protecting it from the byproducts of heating and ensuring a chemically pure environment for processing.

The Core Principle: What "Muffle" Means for Your Work

To understand when to use a muffle furnace, you must first understand the concept of the muffle itself. It is the key differentiator from a standard high-temperature oven.

The Concept of Isolation

The muffle is a physical barrier, typically made of high-temperature ceramic or a specialized metal alloy. This box-like enclosure sits inside the furnace's insulated cabinet.

The heating elements heat the outside of the muffle. The muffle then radiates that heat evenly into the internal chamber, heating the sample indirectly.

Preventing Contamination

This indirect heating is crucial. In a simpler furnace, the sample might be exposed directly to electric heating elements or the flame and combustion gases of a fuel-fired system.

A muffle furnace prevents this contact entirely. This ensures that no particles from the heating elements or chemical byproducts from combustion can contaminate the sample being processed.

Ensuring Temperature Uniformity

Because the entire muffle is heated and then radiates that energy inward, it creates an exceptionally uniform temperature zone. This eliminates hot and cold spots, ensuring that the entire sample receives the exact same thermal treatment, which is critical for repeatable and reliable results.

Primary Applications in Practice

The principle of isolated, uniform heating makes the muffle furnace indispensable for specific technical applications where purity is paramount.

Material Analysis (Ashing)

Ashing is a process used to determine the inorganic, non-combustible content of a sample. The material is heated to a high temperature to burn off all organic matter.

Using a muffle furnace is essential here. It ensures that only the sample's components are present during combustion, preventing airborne contaminants or furnace byproducts from being deposited and altering the final ash weight.

Heat Treatment of Metals

Processes like hardening, annealing, or tempering metals often require a specific atmosphere to prevent oxidation or other surface reactions.

A muffle furnace provides the isolated chamber needed to create this controlled atmosphere. The chamber can be purged of oxygen and filled with an inert gas like argon or nitrogen, protecting the metal's integrity at high temperatures.

Sintering and Ceramics

Sintering is the process of creating a solid object from powder by heating it below its melting point. This is fundamental to creating ceramics, glass, and certain metal parts.

The uniform, clean heat of a muffle furnace ensures that the powdered materials fuse together evenly without introducing impurities that could compromise the final product's structural strength or properties.

Understanding the Key Considerations

While powerful, a muffle furnace is a specialized tool with specific operational characteristics that you must consider.

Atmosphere Control is Not Automatic

A standard muffle furnace provides isolation from the heating source, but its internal chamber still contains air.

If you need a specific, non-air atmosphere (e.g., inert gas or a vacuum), you must select a furnace explicitly designed with the necessary gas inlet/outlet ports and sealing capabilities.

Heating and Cooling Rates

The significant thermal mass of the muffle and surrounding insulation means these furnaces often heat up and cool down more slowly than direct-heating ovens.

This can be an advantage for processes requiring slow, stable temperature ramps, but it can also increase overall processing time.

Material Limitations of the Muffle

The muffle itself has a maximum temperature rating based on its material (e.g., ceramic fiber, silicon carbide). Exceeding this limit can damage the furnace. Furthermore, highly corrosive samples may react with the muffle material at extreme temperatures, requiring special consideration.

Making the Right Choice for Your Goal

Selecting the correct heating instrument depends entirely on whether sample isolation is a critical requirement for your process.

- If your primary focus is simple drying or heating where contamination is not a concern: A standard laboratory or industrial oven is more efficient and cost-effective.

- If your primary focus is determining the precise inorganic content of a sample (ashing): A muffle furnace is the only tool that guarantees accurate, uncontaminated results.

- If your primary focus is heat-treating metals without surface oxidation: A muffle furnace with atmosphere control capabilities is essential.

- If your primary focus is high-temperature materials research or sintering: The clean, uniform heat of a muffle furnace is critical for ensuring data integrity and product quality.

By understanding that a muffle furnace is fundamentally a tool for purity, you can confidently determine when it is the right instrument for your specific technical objective.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | Isolated heating for thermal processes like ashing, sintering, and heat-treating metals. |

| Key Benefit | Prevents contamination and ensures uniform temperature for reliable, pure results. |

| Ideal Applications | Material analysis, metal heat treatment, ceramics sintering in labs and industries. |

Unlock Precision and Purity in Your Lab with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you're conducting ashing, sintering, or metal heat treatment, our furnaces ensure contamination-free, uniform heating for accurate results. Contact us today to discuss how we can tailor a solution for your specific needs and enhance your lab's efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration