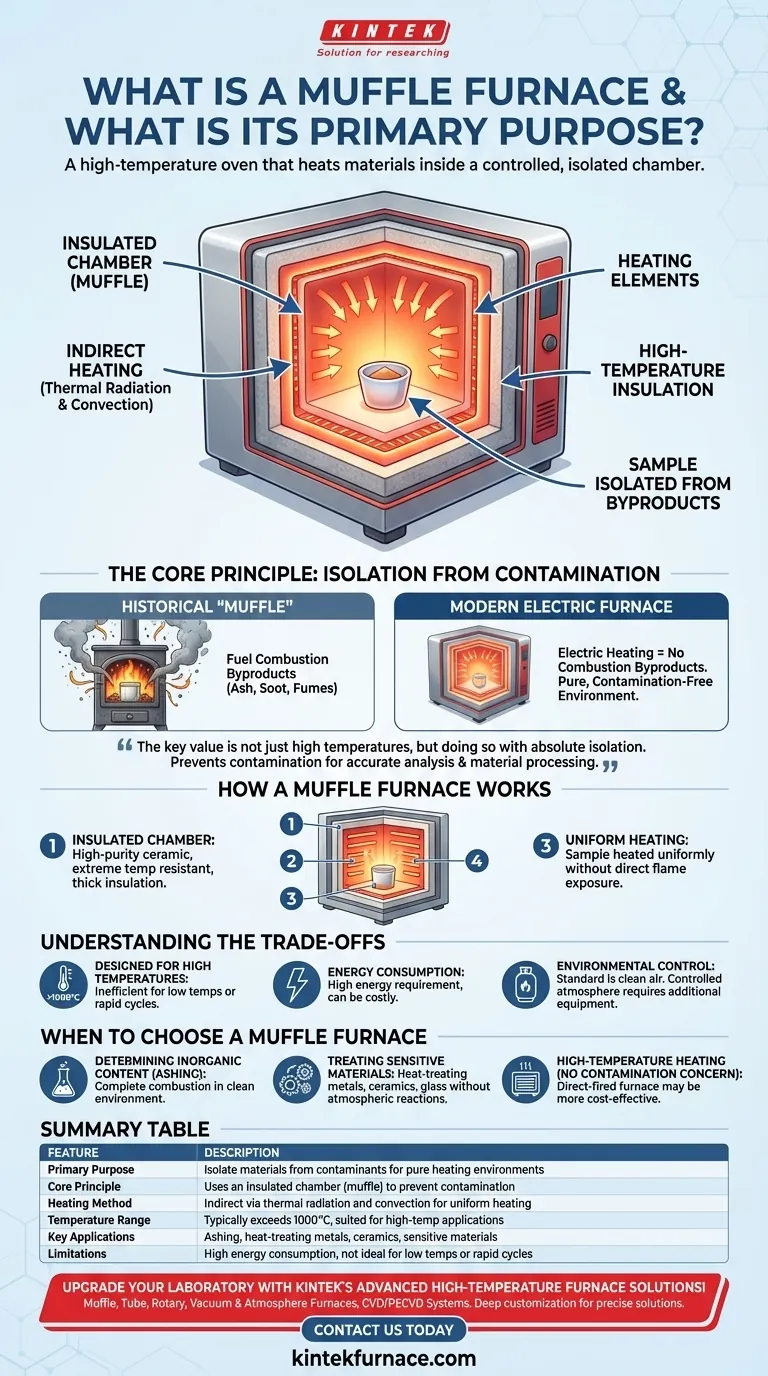

At its core, a muffle furnace is a high-temperature oven that heats materials inside a controlled chamber. Its primary purpose is to isolate the material being heated from the byproducts of the fuel and combustion process, ensuring a pure, contamination-free environment for precise analysis and treatment.

The key value of a muffle furnace is not just achieving high temperatures, but doing so with absolute isolation. This prevents contamination from fuel byproducts, which is critical for accurate scientific analysis and specialized material processing.

The Core Principle: Isolation from Contamination

The defining feature of a muffle furnace is the "muffle" itself—an insulated internal chamber that separates the sample from the heat source's potential contaminants.

The Historical "Muffle"

Historically, furnaces were fired by fuels like coal or gas. To prevent the sample from being contaminated by ash, soot, or fumes, it was placed inside a separate, sealed container or chamber (the muffle). The heat from the combustion would then flow around this chamber, heating the sample indirectly.

Modern Electric Furnaces

Today, most muffle furnaces are electric. While electric heating elements do not produce combustion byproducts, the design principle remains. The term now refers to a furnace with a heavily insulated, sealed chamber that provides a highly stable and pure heating environment, free from external atmospheric influence.

How a Muffle Furnace Works

A muffle furnace achieves its precision through a combination of superior insulation and indirect heating methods.

The Insulated Chamber

The internal chamber is typically made from high-purity ceramic materials capable of withstanding extreme temperatures. This is surrounded by thick layers of high-performance insulation, which minimizes heat loss and allows the furnace to maintain a stable, uniform temperature.

Indirect Heating Mechanism

The furnace heats the material inside the chamber using thermal radiation and convection. The heating elements warm the chamber walls, which then radiate heat evenly throughout the interior. This ensures the sample is heated uniformly without direct exposure to a flame or heating element.

Understanding the Trade-offs

While powerful, muffle furnaces are specialized tools with specific limitations that are important to understand.

Designed for High Temperatures

These furnaces are built for continuous, high-temperature work, often exceeding 1000°C. They are inefficient and generally unsuitable for low-temperature applications or rapid heating and cooling cycles.

Energy Consumption

Maintaining extremely high temperatures requires a significant amount of electrical energy. Their operation can be costly compared to other heating methods, especially for large-scale industrial units.

Environmental Control

While a standard muffle furnace provides a clean air environment, creating a specific atmosphere (such as inert or oxygen-free) often requires additional equipment to purge the chamber and introduce gases like nitrogen or argon.

When to Choose a Muffle Furnace

Your choice depends entirely on whether purity and environmental control are critical to your process.

- If your primary focus is determining inorganic content (ashing): A muffle furnace is the standard tool, as it ensures complete combustion of organic material in a clean environment for accurate residue measurement.

- If your primary focus is treating sensitive materials: The isolated chamber is essential for heat-treating metals, ceramics, or glass where reactions with atmospheric contaminants would compromise the final product.

- If your primary focus is simply high-temperature heating without concern for contamination: A simpler, direct-fired furnace may be a more cost-effective solution for your needs.

Understanding this principle of isolation empowers you to select the correct thermal processing instrument for your specific goal.

Summary Table:

| Feature | Description |

|---|---|

| Primary Purpose | Isolate materials from contaminants for pure heating environments |

| Core Principle | Uses an insulated chamber (muffle) to prevent contamination |

| Heating Method | Indirect via thermal radiation and convection for uniform heating |

| Temperature Range | Typically exceeds 1000°C, suited for high-temperature applications |

| Key Applications | Ashing, heat-treating metals, ceramics, and sensitive materials |

| Limitations | High energy consumption, not ideal for low temperatures or rapid cycles |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance your material processing with pure, contamination-free heating!

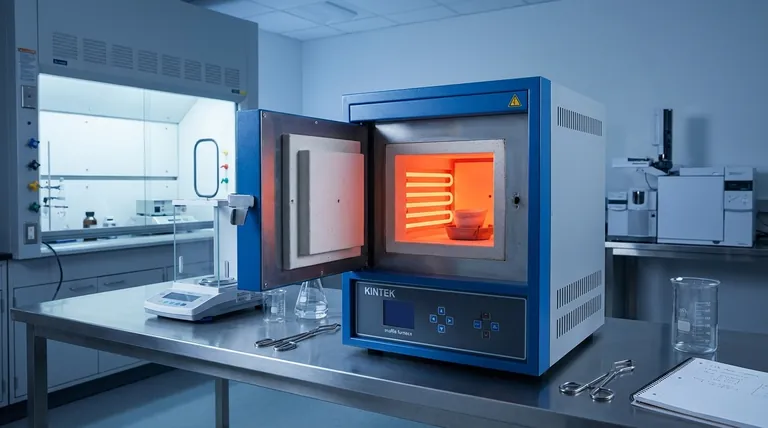

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing