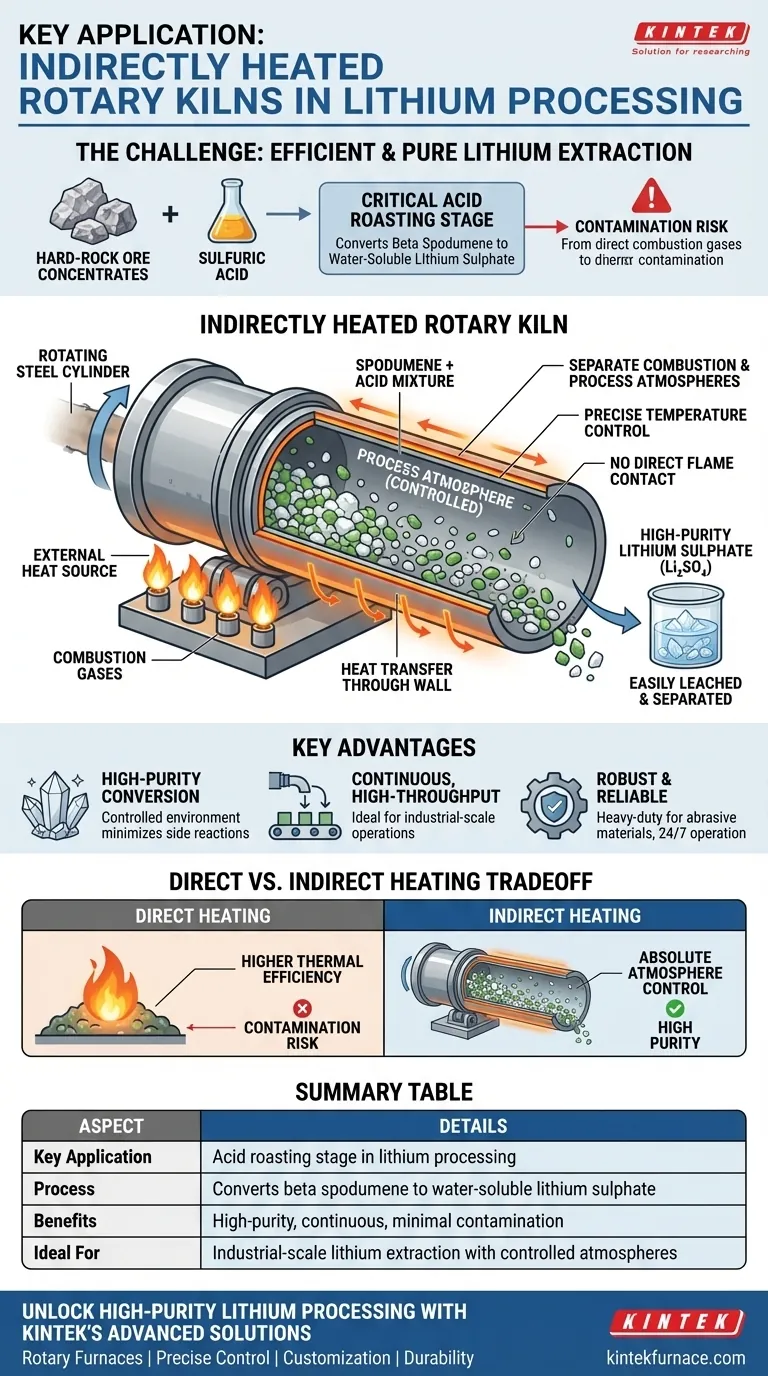

In the context of lithium processing, a key application of an indirectly heated rotary kiln is the acid roasting stage, where beta spodumene is converted into a water-soluble lithium sulphate. This specialized process is critical for efficiently extracting lithium from hard-rock ore concentrates while maximizing recovery rates and minimizing environmental impact.

The core challenge in modern lithium extraction is achieving high-purity chemical conversion at an industrial scale. Indirectly heated rotary kilns solve this by creating a precisely controlled processing atmosphere, isolated from combustion gases, which is essential for the delicate acid roasting chemistry to succeed.

The Critical Role of Acid Roasting

The conversion of spodumene ore into a usable lithium compound is a multi-step thermal and chemical process. The acid roasting stage is one of the most important and technically demanding parts of this chain.

What is Beta Spodumene Conversion?

After raw spodumene is heated to convert it from its alpha to beta phase (a process called calcination), it is mixed with sulfuric acid. The purpose of the indirectly heated rotary kiln is to heat this mixture in a controlled manner.

This "acid roasting" step transforms the lithium within the beta spodumene into lithium sulphate (Li₂SO₄), which is soluble in water. This allows the lithium to be easily leached out in a subsequent step, separating it from the rest of the solid mineral waste.

Why a Controlled Atmosphere is Essential

The chemical reaction during acid roasting is sensitive. Introducing external gases, such as those from direct fuel combustion, would contaminate the process.

This contamination can lead to undesirable side reactions, reduced conversion efficiency, and lower final product purity. An indirectly heated design is therefore not just a preference, but a necessity for this application.

Why Indirect Kilns are the Ideal Tool

An indirectly heated rotary kiln works by heating the exterior of a rotating steel cylinder. The heat transfers through the cylinder wall to the material tumbling inside, without any direct contact between the material and the heat source's flame or exhaust.

Enabling High-Purity Conversion

By separating the heating source from the internal process atmosphere, the kiln allows engineers to maintain the exact chemical environment needed for the acid roast. This precision is the key to achieving high lithium recovery rates.

Continuous, High-Throughput Processing

Unlike batch-style furnaces, a rotary kiln is a continuous system. Material is constantly fed into one end and discharged from the other, making it ideal for the high-volume throughput required in commercial mining operations.

Robust and Reliable Operation

Rotary kilns are known for their heavy-duty construction and long service life. This durability is essential for handling abrasive and corrosive materials like the acid-spodumene mixture in a demanding, 24/7 industrial environment.

Understanding the Broader Context

While vital for lithium, rotary kilns are a foundational technology used across many industries for their versatility. However, the choice between an indirect and direct heating design involves clear trade-offs.

The Direct vs. Indirect Trade-off

Directly heated kilns are generally more energy-efficient, as the hot combustion gases transfer heat directly to the material. They are used for processes like cement production or simple calcination where the material is not sensitive to the exhaust gases.

Indirectly heated kilns trade some of this thermal efficiency for absolute control over the process atmosphere. This makes them essential for applications like acid roasting, pyrolysis, or thermal desorption, where purity is the primary goal.

General Advantages of Rotary Kilns

Beyond the heating method, the rotary kiln design itself offers significant benefits. Its ability to handle a wide variety of feedstock sizes and types, combined with relatively simple operation, makes it a powerful and flexible tool for thermal processing.

Making the Right Choice for Your Goal

When selecting thermal processing equipment, your primary objective dictates the correct technology.

- If your primary focus is high-purity chemical conversion: An indirectly heated kiln is required to maintain a controlled, non-contaminated process atmosphere.

- If your primary focus is maximum thermal efficiency for a robust material: A directly heated kiln is often the more economical choice.

- If your primary focus is industrial-scale throughput and reliability: The continuous, heavy-duty nature of a rotary kiln is a significant advantage over other furnace types.

Ultimately, choosing the right equipment comes down to a clear understanding of your specific chemical process and operational goals.

Summary Table:

| Aspect | Details |

|---|---|

| Key Application | Acid roasting stage in lithium processing |

| Process | Converts beta spodumene to water-soluble lithium sulphate |

| Benefits | High-purity conversion, continuous throughput, minimal contamination |

| Ideal For | Industrial-scale lithium extraction with controlled atmospheres |

Unlock High-Purity Lithium Processing with KINTEK's Advanced Solutions

Are you aiming to maximize lithium recovery and purity in your operations? At KINTEK, we specialize in delivering cutting-edge high-temperature furnace solutions tailored to your unique needs. Our expertise in R&D and in-house manufacturing ensures robust and reliable equipment, including Rotary Furnaces and other systems designed for demanding environments like lithium acid roasting.

By partnering with us, you benefit from:

- Precise Control: Achieve optimal process atmospheres for high-yield chemical conversions.

- Customization: Leverage our deep customization capabilities to meet specific experimental and industrial requirements.

- Durability: Rely on equipment built for 24/7 operation with minimal downtime.

Don't let equipment limitations hold back your lithium processing efficiency. Contact us today to discuss how our Rotary Furnaces and other products can enhance your lab or plant's performance and drive your success forward!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions