In essence, a furnace retort is a furnace built around a sealed chamber. It is a specialized piece of equipment used for industrial and laboratory processes that demand precise atmospheric control. The defining feature is the "retort" itself—a sealed vessel that isolates the material being heated from the furnace's heating elements and the outside air, allowing for a pure, custom-managed environment.

The true purpose of a retort furnace is not just to generate heat, but to create a highly controlled chemical environment. This control allows for processes like brazing, hardening, and material synthesis that would be impossible or ineffective in an open-air furnace.

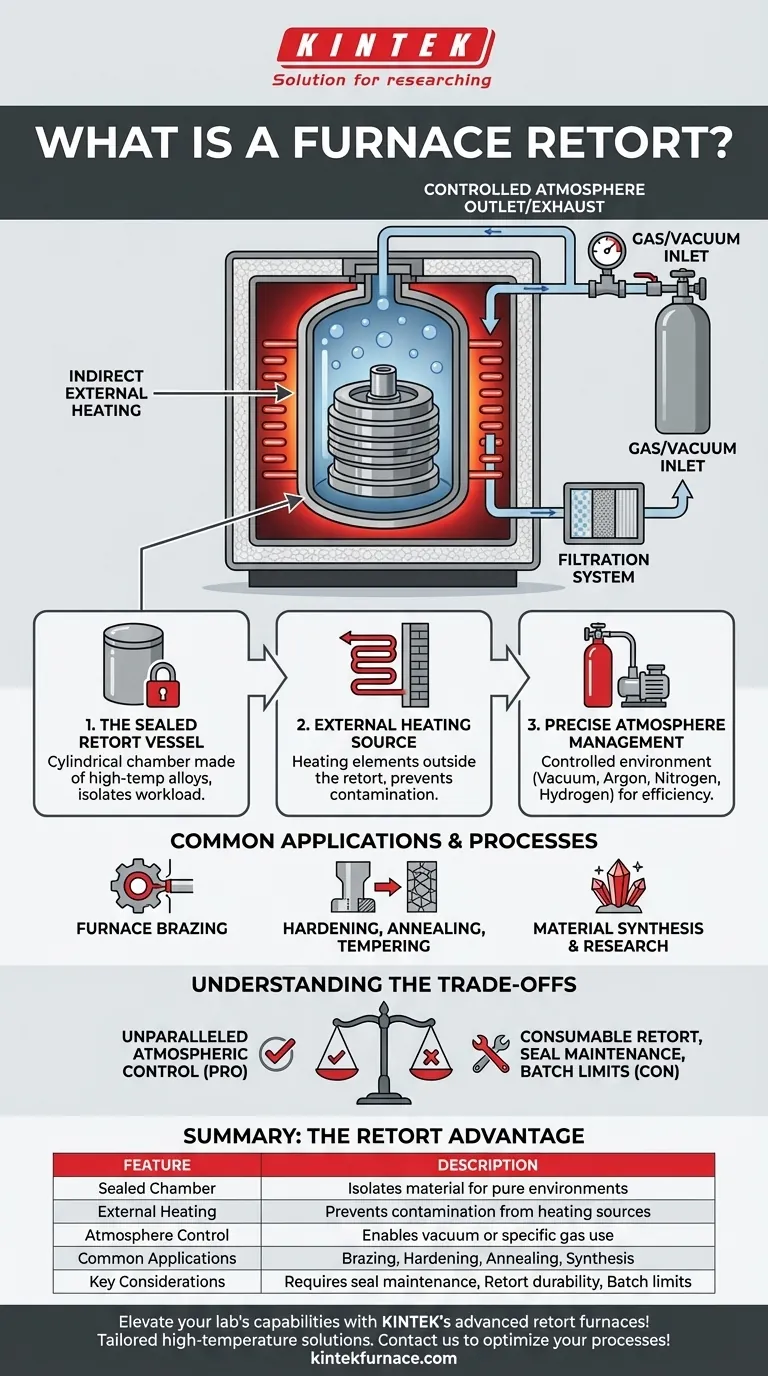

How a Retort Furnace Achieves Atmospheric Control

The design of a retort furnace is fundamentally about separation. By isolating the workload in a sealed chamber, it gains complete command over the atmospheric conditions surrounding the material.

The Sealed Retort Vessel

The core of the system is the retort, typically a cylindrical vessel made from high-temperature metal alloys. This chamber contains the material being processed and is sealed shut, creating a closed system.

External Heating Source

The heating elements, whether electric resistance heaters or gas burners, are located outside the retort. Heat is transferred through the walls of the retort to the material inside. This external heating method prevents any byproducts of combustion or contamination from the heating elements from affecting the workpiece.

Precise Atmosphere Management

Because the retort is a closed and sealed space, its atmosphere can be precisely managed. This allows operators to run processes in a vacuum or introduce specific gases like argon, nitrogen, or hydrogen. The sealed design makes this highly efficient, requiring very low gas usage compared to furnaces that are continuously purged.

Common Applications and Processes

The ability to control the atmosphere unlocks a range of critical thermal processes where material chemistry is paramount.

Furnace Brazing

Brazing involves joining two metal components using a filler metal with a lower melting point. Performing this in a retort furnace with an inert or reducing atmosphere prevents oxidation, resulting in a clean, strong, and flux-free joint.

Hardening, Annealing, and Tempering

Many heat treatment processes require controlled atmospheres to prevent unwanted surface reactions. A retort furnace can prevent decarburization (carbon loss) in steels or surface scaling (oxidation), ensuring the material's final properties meet exact specifications. Rotary retort furnaces are often used for the continuous processing of small parts.

Material Synthesis and Research

In scientific and R&D settings, retort furnaces are essential for high-temperature experiments. They allow researchers to synthesize new materials, grow crystals, or conduct chemical reactions in specific, non-reactive gaseous environments.

Understanding the Trade-offs

While powerful, the retort design introduces specific considerations that are critical to understand.

Purity Comes at a Price

The primary benefit is unparalleled atmospheric control, which is non-negotiable for certain processes. However, the retort itself is a consumable component that can degrade, warp, or crack over time due to thermal cycling, requiring inspection and eventual replacement.

The Seal is Everything

The integrity of the retort's seal is the most critical factor for successful operation. Any leak, no matter how small, compromises the atmospheric purity and can ruin the process. This demands careful maintenance and handling.

Batch Size vs. Throughput

Standard retort furnaces are often batch-style processes, limited by the physical volume of the retort. While rotary retort systems allow for continuous flow, the overall throughput may be lower than large, open-air continuous belt furnaces.

Making the Right Choice for Your Process

Your decision to use a retort furnace should be guided by the specific chemical and physical requirements of your material.

- If your primary focus is achieving maximum material purity and preventing any surface oxidation: A retort furnace is the definitive solution due to its sealed, controlled atmosphere.

- If your primary focus is high-volume heat treatment where minor surface oxidation is acceptable: A non-retort, continuous conveyor furnace may offer higher throughput and lower operational complexity.

- If your primary focus is continuous hardening of small parts with tight specifications: A rotary retort furnace provides an excellent balance of atmospheric control and automated throughput.

Ultimately, a retort furnace is the tool of choice when the integrity of the atmosphere is as critical to the outcome as the temperature itself.

Summary Table:

| Feature | Description |

|---|---|

| Sealed Chamber | Isolates material from external elements for pure environments |

| External Heating | Prevents contamination from heating sources |

| Atmosphere Control | Enables vacuum or specific gas use (e.g., argon, nitrogen) |

| Common Applications | Brazing, hardening, annealing, material synthesis |

| Key Considerations | Requires seal maintenance, batch processing limits, retort durability |

Elevate your lab's capabilities with KINTEK's advanced retort furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, delivering superior atmospheric control and efficiency. Contact us today to discuss how our furnaces can optimize your processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance