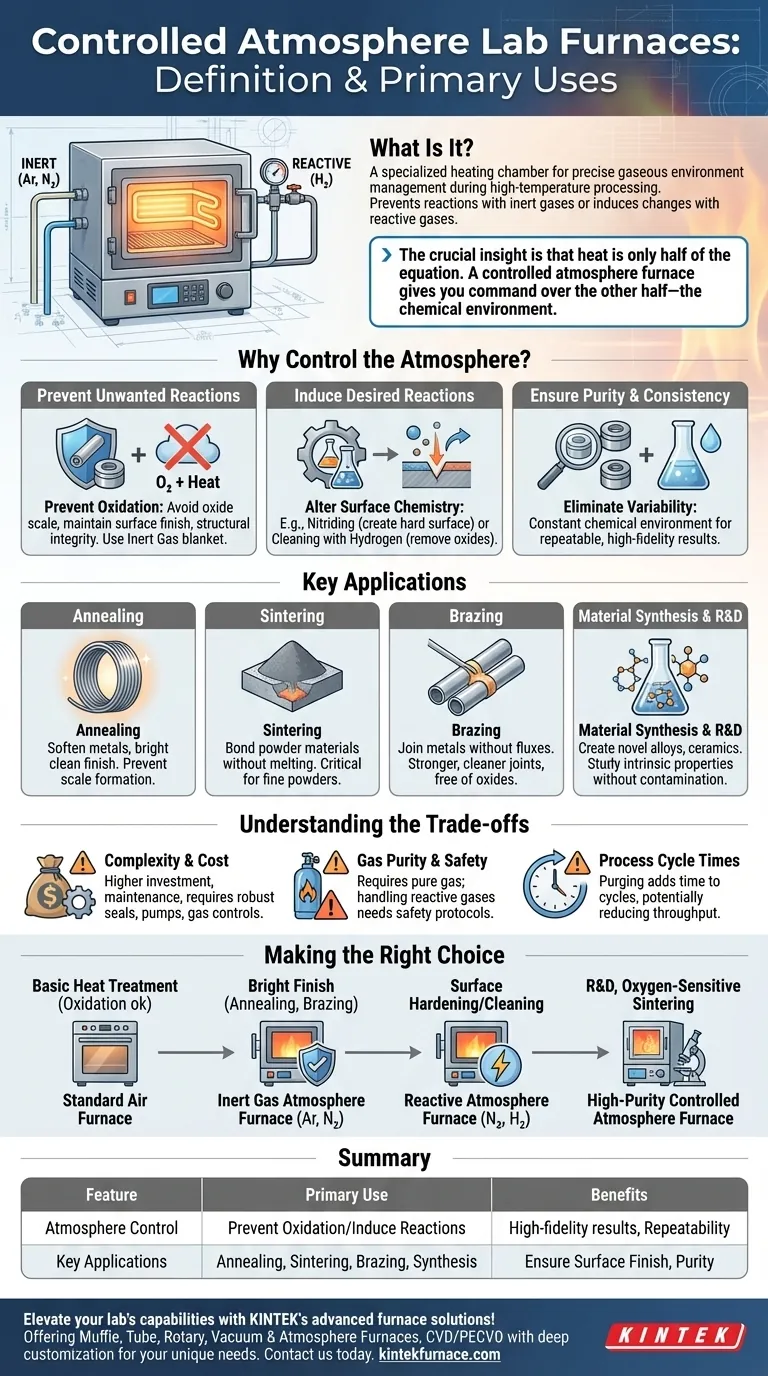

In material science and advanced manufacturing, a controlled atmosphere furnace is a specialized heating chamber that allows for the precise management of the gaseous environment surrounding a material during processing. Unlike a standard furnace that operates in ambient air, this equipment uses a sealed chamber that can be filled with specific inert gases like nitrogen and argon to prevent reactions, or reactive gases like hydrogen to induce chemical changes. Its primary uses are for high-fidelity processes such as annealing, sintering, brazing, and material synthesis where preventing oxidation or other atmospheric contamination is critical to the final outcome.

The crucial insight is that heat is only half of the equation in advanced material processing. A controlled atmosphere furnace gives you command over the other half—the chemical environment—transforming a simple furnace into a tool for precision chemical engineering at high temperatures.

The Core Principle: Why Control the Atmosphere?

The decision to use a controlled atmosphere furnace is driven by the need to manage chemical reactions on a material's surface at elevated temperatures. In open air, high heat acts as a catalyst for unwanted reactions, primarily with oxygen and water vapor.

To Prevent Unwanted Reactions (Protective Atmospheres)

Most materials, especially metals, will rapidly oxidize when heated in air. This forms a layer of oxide scale on the surface, which can ruin surface finish, alter dimensions, and compromise the material's structural or electrical properties.

By purging the air from the furnace chamber and replacing it with an inert gas like argon or nitrogen, you create a protective blanket. These gases do not react with the material, allowing it to be heated and cooled without surface degradation.

To Induce Desired Reactions (Reactive Atmospheres)

In some applications, the goal is not to prevent a reaction but to cause a specific one. A controlled atmosphere furnace allows you to introduce reactive gases to deliberately alter a material's surface chemistry.

For example, introducing nitrogen in a process called nitriding can create an extremely hard surface on steel parts. Using hydrogen can serve as a powerful reducing agent, stripping oxygen from a previously oxidized part to clean its surface at a chemical level.

To Ensure Purity and Consistency

For researchers and manufacturers in fields like electronics or aerospace, process repeatability is paramount. Ambient air is a variable mixture of gases, moisture, and particulates.

A controlled atmosphere furnace eliminates this variability. By using a pure, controlled gas source, you ensure that every part processed under the same parameters experiences the exact same chemical environment, leading to highly consistent and predictable results.

Key Applications in Practice

The ability to control the chemical environment opens up a range of processes that are impossible or impractical in a standard air furnace.

Annealing

Annealing is a heat treatment process used to soften metals, increase their ductility, and relieve internal stresses. When a bright, clean surface finish is required post-process, a protective atmosphere is essential to prevent the formation of oxide scale.

Sintering

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. It is fundamental to powder metallurgy and ceramics. The fine powders used have a massive surface area, making them extremely susceptible to oxidation, which would inhibit proper bonding. An inert or reducing atmosphere is critical for success.

Brazing

Brazing joins two or more metal items by melting and flowing a filler metal into the joint. For the filler to wet and bond properly to the base metals, the surfaces must be perfectly clean and free of oxides. Performing brazing in a controlled atmosphere eliminates the need for aggressive chemical fluxes and results in stronger, cleaner joints.

Material Synthesis and Research

For material scientists creating novel alloys, ceramics, or composites, the furnace acts as a high-temperature reaction vessel. A controlled atmosphere allows them to study the intrinsic properties of a material without the interfering effects of oxidation, ensuring that their experimental results are valid and untainted by environmental contamination.

Understanding the Trade-offs

While powerful, these furnaces introduce complexities and costs not present with simpler equipment.

Complexity and Cost

A controlled atmosphere furnace is a more sophisticated system. It requires robust seals, vacuum pumps for purging air, and precise gas flow control systems. This translates to a higher initial investment and more involved maintenance.

Gas Purity and Safety

The effectiveness of the process is directly tied to the purity of the process gas. Any contamination in the gas supply can compromise the results. Furthermore, handling reactive or flammable gases like hydrogen requires significant safety protocols, leak detection systems, and proper facility ventilation.

Process Cycle Times

Achieving a pure atmosphere is not instantaneous. The furnace chamber must first be purged of air, often using a vacuum pump or a series of dilution purges with an inert gas. This adds time to the beginning and end of each heating cycle, potentially reducing overall throughput compared to a simple furnace.

Making the Right Choice for Your Process

Your choice of thermal processing equipment should be dictated by the required properties of your final product.

- If your primary focus is basic heat treatment where surface oxidation is acceptable or will be machined off later: A standard air furnace is often the most cost-effective solution.

- If your primary focus is achieving a bright, clean metal finish after annealing or brazing: A controlled atmosphere furnace with an inert gas like nitrogen or argon is essential.

- If your primary focus is hardening a component's surface or cleaning away oxides: A furnace capable of handling reactive atmospheres like nitrogen or hydrogen is required.

- If your primary focus is R&D, sintering oxygen-sensitive powders, or manufacturing for high-tech applications: A high-purity controlled atmosphere furnace is non-negotiable to ensure data integrity and product quality.

Ultimately, a controlled atmosphere furnace elevates high-temperature processing from a simple heating exercise into a precision tool for material engineering.

Summary Table:

| Feature | Description | Primary Use |

|---|---|---|

| Atmosphere Control | Manages gases like nitrogen, argon, or hydrogen in a sealed chamber | Prevents oxidation or induces specific chemical reactions |

| Key Applications | Annealing, sintering, brazing, material synthesis | Ensures surface finish, material purity, and process consistency |

| Benefits | High-fidelity results, repeatability, protection from contamination | Ideal for R&D, electronics, aerospace, and advanced manufacturing |

Elevate your lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, whether for annealing, sintering, or material synthesis. Contact us today to discuss how our tailored solutions can enhance your precision and efficiency in material processing!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance