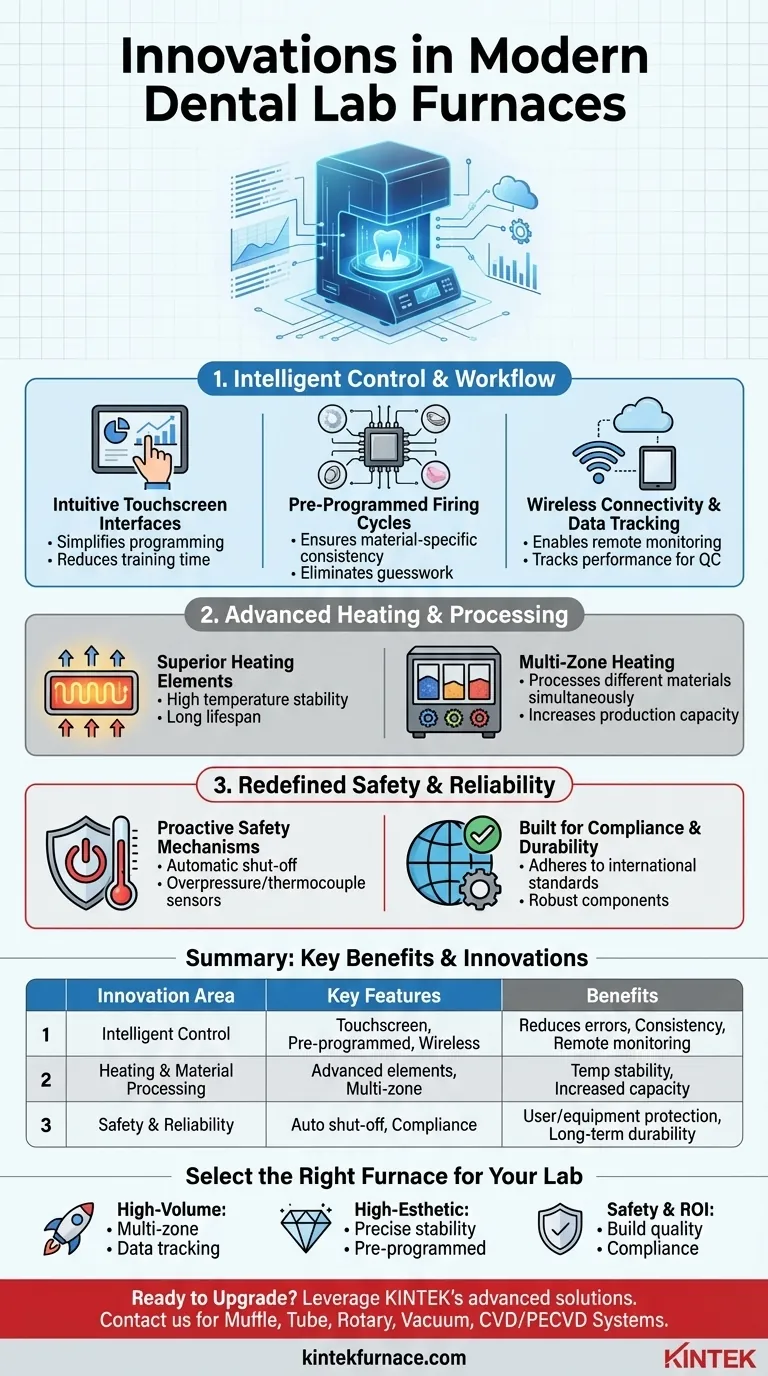

At their core, modern dental lab furnaces are defined by three key areas of innovation: intelligent digital controls, advanced material processing capabilities, and deeply integrated safety systems. These advancements move furnaces from simple heating devices to sophisticated, data-driven instruments that enhance precision, consistency, and operational efficiency for the entire dental laboratory.

The most significant shift in modern furnace technology is not just the addition of new features, but the integration of these features into a cohesive system. This system is designed to minimize human error, maximize material performance, and provide unprecedented control over the final prosthetic outcome.

The Shift Toward Intelligent Control

The most visible innovations are in how technicians interact with the furnace. The goal has shifted from manual input to automated, repeatable precision, directly impacting workflow efficiency and the quality of restorations.

Intuitive Touchscreen Interfaces

Modern furnaces have replaced archaic buttons and dials with high-resolution touchscreen displays. This simplifies programming complex multi-stage firing cycles, reduces the learning curve for new technicians, and provides clear, at-a-glance feedback on the current status.

Pre-Programmed Firing Cycles

To ensure optimal results for specific materials like zirconia or lithium disilicate, manufacturers now embed pre-programmed settings directly into the furnace's software. This eliminates guesswork and ensures that every restoration is fired according to the material manufacturer's exact specifications, leading to greater consistency and reduced remakes.

Wireless Connectivity and Data Tracking

Many advanced furnaces now feature wireless connectivity. This allows lab managers to monitor cycle progress remotely, receive alerts upon completion, and track equipment usage and performance over time. This data is invaluable for quality control, scheduling maintenance, and optimizing lab throughput.

Innovations in Heating and Material Processing

Beyond the controls, the fundamental heating technology has evolved to provide greater flexibility and reliability, accommodating the complex demands of new dental materials.

Advanced Heating Elements and Materials

Furnaces are now constructed with superior, high-quality heat-resistant materials that ensure excellent temperature stability and a long operational lifespan. This stability is critical for preventing thermal shock and achieving the precise crystalline structure required for modern ceramics.

Multi-Zone Heating Capabilities

A significant innovation for high-volume labs is the introduction of multiple, independent heating zones. This allows a single furnace to simultaneously process different materials or run multiple, distinct firing cycles, drastically increasing the lab's production capacity without increasing its physical footprint.

Understanding the Trade-offs

While these innovations offer clear advantages, it is crucial to evaluate them critically in the context of your lab's specific needs.

Cost vs. Capability

Advanced features like wireless connectivity and multi-zone heating come at a premium. A smaller lab specializing in a single material may not see a return on investment from a furnace designed for high-volume, varied production.

Complexity and Reliance on Software

While touchscreens are intuitive, a deep reliance on software introduces a new point of potential failure. It's essential to consider the manufacturer's reputation for software stability and support. A furnace that is offline due to a software bug can halt production entirely.

Redefining Safety and Reliability

Modern furnace design places a heavy emphasis on protecting the user, the lab, and the work itself. These are not merely add-ons but core components of a reliable system.

Proactive Safety Mechanisms

Furnaces now incorporate a suite of active safety features. Automatic shut-off systems prevent catastrophic overheating, while sensors for overpressure and thermocouple breaks provide early warnings, allowing technicians to intervene before a cycle is ruined or the equipment is damaged.

Built for Durability and Compliance

Leading manufacturers build their equipment to comply with strict international safety standards. This adherence, combined with the use of robust internal components, signals a commitment to long-term reliability and provides assurance that the furnace is a safe and durable investment.

Selecting the Right Furnace for Your Lab's Goals

Choosing a furnace is a strategic decision that should align with your operational priorities.

- If your primary focus is high-volume production: Prioritize furnaces with multi-zone heating capabilities and robust data-tracking software to maximize throughput and efficiency.

- If your primary focus is specialized, high-esthetic restorations: Emphasize models with precise temperature stability and a wide range of accurate, pre-programmed cycles for advanced materials.

- If your primary focus is safety and long-term ROI: Scrutinize the build quality, the comprehensiveness of the safety mechanisms, and the manufacturer's compliance with industry standards.

Understanding these underlying innovations empowers you to look beyond the feature list and invest in a furnace that truly supports your lab's mission.

Summary Table:

| Innovation Area | Key Features | Benefits |

|---|---|---|

| Intelligent Control | Touchscreen interfaces, pre-programmed cycles, wireless connectivity | Reduces errors, ensures consistency, enables remote monitoring |

| Heating & Material Processing | Advanced heating elements, multi-zone heating | Improves temperature stability, increases production capacity |

| Safety & Reliability | Automatic shut-off, compliance with standards | Protects users and equipment, ensures long-term durability |

Ready to upgrade your dental lab with cutting-edge furnace technology? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Enhance your lab's precision, efficiency, and safety—contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations