In short, a wide range of industries can benefit from electromagnetic induction rotary kilns, including metallurgy, mineral processing, cement production, chemical manufacturing, and waste management. These kilns are particularly advantageous for any process where precise temperature control, high energy efficiency, and uniform material heating are critical for achieving high-quality end products and optimizing operational costs.

The core advantage of electromagnetic induction rotary kilns is not just that they heat materials, but how they do it. By using a non-contact, highly controllable energy source, they offer a level of precision and efficiency that traditional fuel-fired kilns struggle to match, directly translating to superior product quality and lower long-term operating expenses.

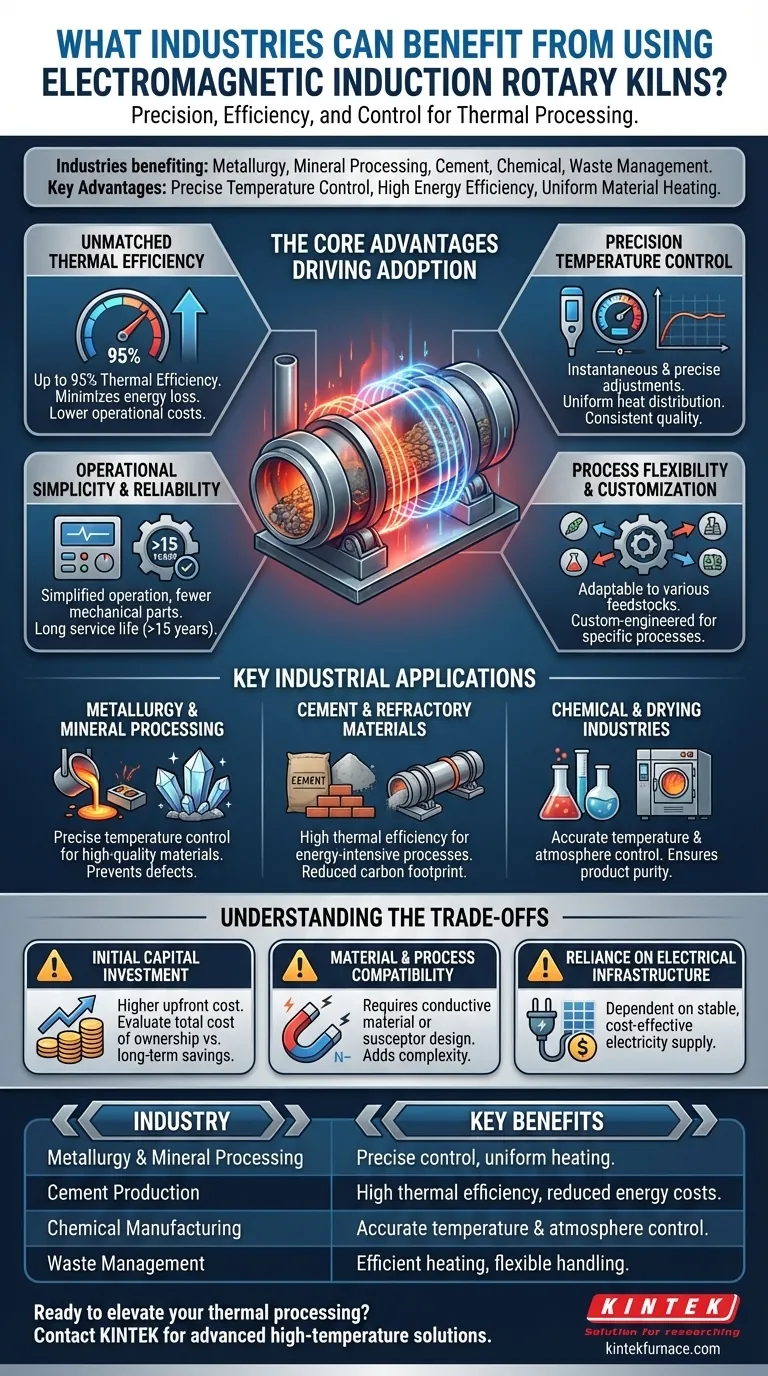

The Core Advantages Driving Adoption

The decision to use an electromagnetic induction rotary kiln is driven by a distinct set of technical and financial benefits that solve common challenges in thermal processing.

Unmatched Thermal Efficiency

Electromagnetic induction directly heats the material (or a conductive cylinder), minimizing energy loss to the surrounding environment. This method can achieve thermal efficiencies of up to 95%, a significant improvement over traditional gas or oil-fired kilns.

This high efficiency dramatically reduces energy consumption and lowers operational costs, especially in energy-intensive applications.

Precision Temperature Control

Induction heating allows for instantaneous and precise power adjustments. This provides exceptionally tight control over the material's temperature profile, ensuring a consistent and uniform heat distribution throughout the batch.

The rotating mechanism of the kiln further guarantees that all material is heated evenly. This combination prevents local overheating or underheating, which is critical for producing high-purity materials and avoiding defects.

Operational Simplicity and Reliability

These kilns eliminate the complexities of fuel storage, delivery, and combustion management. Operation is simplified to setting and monitoring electrical parameters.

With fewer mechanical parts related to fuel burning and a robust design, these systems often boast a long service life of over 15 years with comprehensive safety protections built in.

Process Flexibility and Customization

Induction rotary kilns are highly adaptable. They can be engineered to handle a wide variety of feedstocks and can be tailored to meet the specific temperature, atmosphere, and residence time requirements of a given process.

This flexibility makes them suitable for both large-scale, continuous production and smaller, more specialized applications that demand narrow processing windows.

Key Industrial Applications in Detail

The technical advantages of induction heating make it a superior choice for several demanding industries.

Metallurgy and Mineral Processing

In metallurgy and the extraction of minerals, achieving specific crystalline structures and material properties is paramount. The precise temperature control of an induction kiln ensures these targets are met repeatably.

The uniform heating prevents the formation of undesirable phases or impurities, leading to a higher quality and more valuable final product, from steel production to processing rare earth elements.

Cement and Refractory Materials

Manufacturing cement and refractory materials requires sustained, high temperatures. The high thermal efficiency of induction kilns translates directly into significant energy savings and a reduced carbon footprint for these energy-intensive processes.

The heavy-duty construction and long-term reliability are also well-suited for the demanding, 24/7 operational environment common in these industries.

Chemical and Drying Industries

For chemical reactions and drying sensitive materials, precise control over both temperature and atmosphere is non-negotiable. Induction heating provides this control, enabling reactions to proceed efficiently without degrading the product.

This is especially valuable when producing high-purity chemicals or drying materials where even minor temperature fluctuations could compromise quality.

Understanding the Trade-offs

While powerful, this technology has considerations that must be weighed for any potential application.

Initial Capital Investment

Electromagnetic induction systems typically have a higher upfront capital cost compared to conventional fuel-fired kilns. The evaluation must include a total cost of ownership analysis, balancing the higher initial investment against long-term energy savings and reduced maintenance.

Material and Process Compatibility

Induction heating works by inducing a current in an electrically conductive material. If your target material is not conductive, it must be processed within a conductive drum (a susceptor), which then heats the material via radiation and convection. This adds a layer of design complexity.

Reliance on Electrical Infrastructure

Operation is entirely dependent on a stable and cost-effective supply of electricity. In regions with high electricity costs or an unreliable grid, a traditional fuel-fired kiln may be a more pragmatic choice. Your operational cost model shifts from fuel management to electricity price management.

Making the Right Choice for Your Goal

To determine if an electromagnetic induction rotary kiln is the correct solution, consider your primary operational driver.

- If your primary focus is product quality and consistency: The unparalleled temperature control and uniform heating make this technology an ideal choice for high-value materials.

- If your primary focus is long-term operational cost: The high thermal efficiency and simplified maintenance can deliver significant savings that justify the initial investment.

- If your primary focus is process flexibility and environmental impact: The ability to handle diverse materials with zero direct emissions makes this a forward-looking and adaptable solution.

Ultimately, choosing this technology is an investment in precision, efficiency, and control for your thermal processing needs.

Summary Table:

| Industry | Key Benefits |

|---|---|

| Metallurgy & Mineral Processing | Precise temperature control for high-quality materials, uniform heating to prevent defects |

| Cement Production | High thermal efficiency up to 95%, reduced energy costs and carbon footprint |

| Chemical Manufacturing | Accurate temperature and atmosphere control for pure products, operational reliability |

| Waste Management | Efficient heating for processing, flexibility in handling various materials |

Ready to elevate your thermal processing with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, tailored for industries like metallurgy, cement, and chemicals. Our deep customization capability ensures we meet your unique experimental needs, helping you achieve superior product quality and cost savings. Contact us today to discuss how our electromagnetic induction rotary kilns can transform your operations!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems