In essence, Silicon Carbide (SiC) heating elements are designed for the most demanding high-temperature industrial processes. They are the go-to solution in industries such as metallurgy, ceramics, glass manufacturing, semiconductor production, and chemical processing, where extreme heat, reliability, and operational efficiency are non-negotiable.

The core reason SiC elements are so widely adopted is their ability to deliver consistent, rapid heat in extreme environments where conventional metallic elements would fail. This combination of high-temperature performance, durability, and energy efficiency makes them a critical component for modern industrial heating.

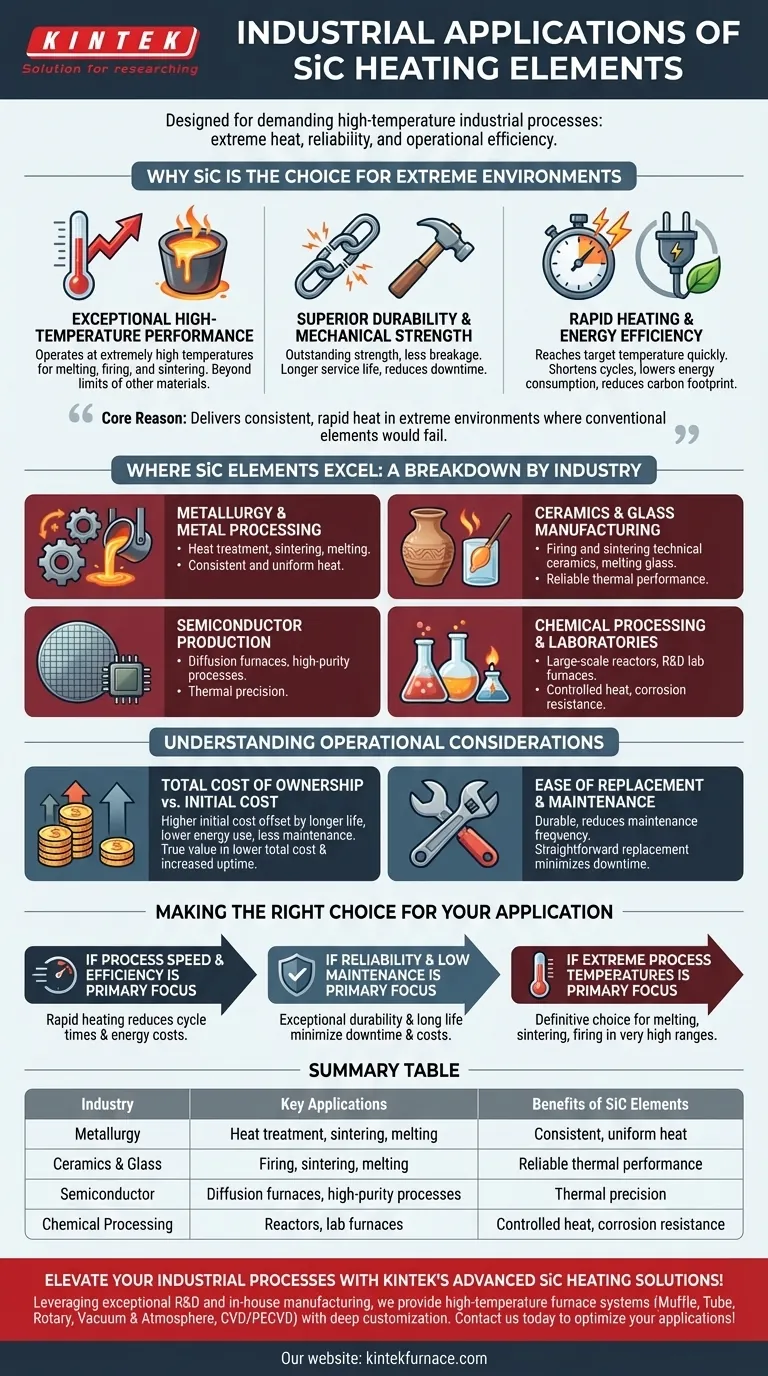

Why SiC is the Choice for Extreme Environments

The suitability of SiC elements is not based on a single attribute, but on a combination of properties that directly address the challenges of high-temperature industrial work.

Exceptional High-Temperature Performance

SiC elements can operate at extremely high temperatures, making them essential for processes that require intense, controlled heat.

This capability is fundamental for applications like melting metals, firing advanced ceramics, and producing molten glass, where process temperatures are often beyond the limits of other materials.

Superior Durability and Mechanical Strength

These elements exhibit outstanding mechanical strength, making them far less prone to breakage during operation or maintenance.

This inherent durability translates to a longer service life, reducing the need for frequent replacements and minimizing costly production downtime.

Rapid Heating and Energy Efficiency

SiC heaters can reach their target temperature very quickly. This rapid thermal response shortens process cycle times and significantly reduces energy consumption.

Over the long term, this efficiency lowers operational costs and contributes to a smaller carbon footprint, enhancing industrial sustainability.

Where SiC Elements Excel: A Breakdown by Industry

Different industries leverage the unique benefits of SiC elements to optimize their specific high-temperature processes.

Metallurgy and Metal Processing

In metallurgy, SiC elements are used for heat treatment, sintering, and melting of various metals and alloys. Their ability to deliver consistent and uniform heat is critical for achieving desired material properties.

Ceramics and Glass Manufacturing

The firing and sintering of technical ceramics, as well as the melting of glass, require sustained, extreme heat. SiC elements provide the reliable thermal performance needed for these demanding furnace applications.

Semiconductor Production

The manufacturing of semiconductors involves high-purity processes conducted at very high temperatures. SiC elements are used in diffusion furnaces and other equipment where thermal precision is paramount.

Chemical Processing and Laboratories

In both large-scale chemical reactors and smaller R&D lab furnaces, SiC elements provide controlled, reliable heat. Their resistance to corrosion is also a key advantage when working with reactive chemicals.

Understanding the Operational Considerations

While SiC elements are highly robust, understanding their operational context is key to maximizing their value and lifespan. They represent an investment in performance, and their total cost of ownership is where they truly shine.

Total Cost of Ownership vs. Initial Cost

SiC elements may have a higher initial purchase price compared to some alternatives. However, this is offset by their longer service life, reduced energy consumption, and lower maintenance needs.

The true value is realized in the lower total cost of ownership and increased operational uptime over the element's lifespan.

Ease of Replacement and Maintenance

The durability of SiC reduces the frequency of maintenance, but when replacement is needed, it is typically straightforward.

This "ease of replacement" is an important design consideration, ensuring that furnace downtime is kept to an absolute minimum during planned maintenance cycles.

Making the Right Choice for Your Application

Selecting the right heating element depends on your primary operational goal. SiC technology offers distinct advantages across several performance metrics.

- If your primary focus is process speed and efficiency: The rapid heating capabilities of SiC will reduce cycle times and lower energy costs.

- If your primary focus is reliability and low maintenance: The exceptional durability and long service life of SiC elements minimize downtime and replacement costs.

- If your primary focus is achieving extreme process temperatures: SiC is the definitive choice for applications like melting, sintering, and firing that operate in very high-temperature ranges.

Ultimately, choosing SiC heating elements is an investment in process stability, efficiency, and long-term performance.

Summary Table:

| Industry | Key Applications | Benefits of SiC Elements |

|---|---|---|

| Metallurgy | Heat treatment, sintering, melting | Consistent, uniform heat for material properties |

| Ceramics & Glass | Firing, sintering, melting | Reliable thermal performance in extreme heat |

| Semiconductor | Diffusion furnaces, high-purity processes | Thermal precision and high-temperature capability |

| Chemical Processing | Reactors, lab furnaces | Controlled heat, corrosion resistance |

Elevate your industrial processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering reliability, efficiency, and long-term performance. Contact us today to discuss how we can optimize your high-temperature applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions