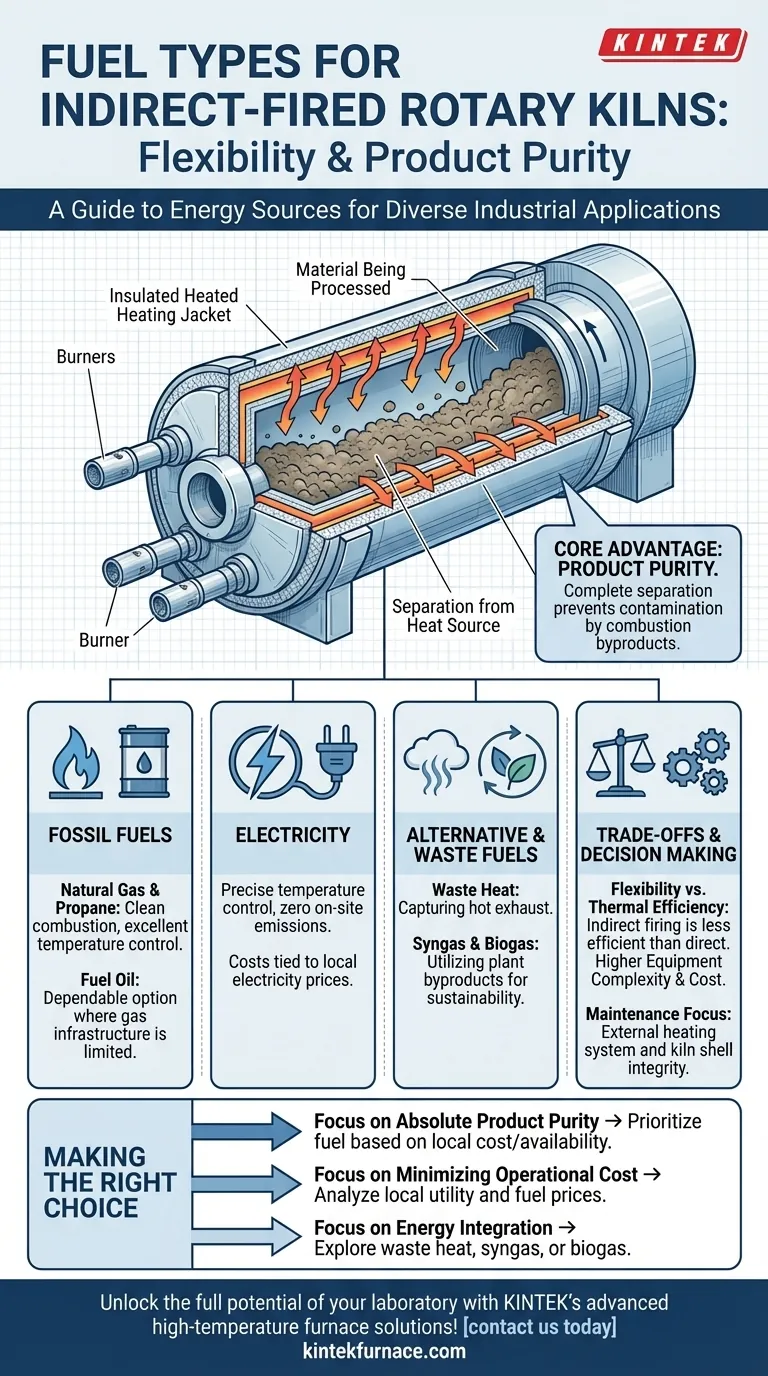

In short, indirect-fired rotary kilns can operate on a wide variety of fuels. The most common options include natural gas, propane, fuel oil, and electricity. Additionally, they are uniquely suited to utilize alternative energy sources such as waste heat from other industrial processes, syngas, or biogas.

The defining advantage of an indirect-fired kiln is the complete separation between the heat source and the material being processed. This gives you significant flexibility in fuel choice, driven primarily by cost and availability, rather than by compatibility with your process material.

The Principle of Indirect Firing

To understand the fuel options, you must first understand the mechanism. Unlike direct-fired kilns where combustion gases mix with the material, an indirect kiln functions more like an oven.

How It Works

An external heat source heats the outside of the rotating kiln shell. This heat then transfers through the shell wall via conduction to the material tumbling inside.

The Core Advantage: Product Purity

This separation is critical. It prevents any contamination of the process material by combustion byproducts, ash, or other impurities from the fuel source. This is essential for processing high-purity materials, sensitive chemicals, or food-grade products.

A Breakdown of Fuel Options

The external heating system can be designed to accommodate several energy sources, each with its own operational profile.

Natural Gas & Propane

These are the most common fossil fuels for this application. They offer clean combustion and excellent temperature control, making them a reliable and well-understood choice for most industrial settings.

Fuel Oil

Fuel oil is another viable fossil fuel. It serves as a dependable option, particularly in regions where natural gas infrastructure is less developed or where oil is more cost-effective.

Electricity

Electric-powered kilns use resistive heating elements mounted in an insulated jacket around the kiln shell. This provides exceptionally precise temperature control and produces zero on-site emissions, though the operational cost is tied directly to local electricity prices.

Alternative & Waste Fuels

This is where indirect-fired kilns show unique versatility. Because the combustion happens outside the process chamber, they can be designed to run on:

- Waste Heat: Capturing hot exhaust gas from another furnace or process to heat the kiln.

- Syngas or Biogas: Using synthetic or biologically derived gases from other plant operations as a fuel source.

Understanding the Trade-offs

While fuel flexibility is a major benefit, it comes with important considerations that differ from direct-fired systems.

Fuel Flexibility vs. Thermal Efficiency

Indirect firing is inherently less thermally efficient than direct firing. Heat must first be transferred to the kiln shell and then through it, resulting in greater heat loss to the surrounding environment. This is the fundamental trade-off made to achieve product purity.

Equipment Complexity and Cost

An indirect kiln requires an external furnace, heating jacket, or combustion chamber. This adds a layer of complexity, a larger physical footprint, and higher initial capital cost compared to a simpler direct-fired design.

Maintenance Considerations

Maintenance is focused on two areas: the external heating system (burners, electrical elements) and the kiln shell. The shell is subjected to high thermal stress from the outside, which requires careful material selection and monitoring to ensure its integrity over time.

Making the Right Choice for Your Goal

Selecting a fuel is a strategic decision based on your specific operational priorities.

- If your primary focus is absolute product purity: Indirect firing is non-negotiable, and your fuel choice should be based on local cost and availability.

- If your primary focus is minimizing operational cost: Conduct a detailed analysis of local utility and fuel prices for natural gas, electricity, and oil, as this will be your largest ongoing expense.

- If your primary focus is energy integration or sustainability: Explore using waste heat, syngas, or biogas from existing processes to improve overall plant efficiency and lower your carbon footprint.

Ultimately, the right fuel choice aligns your kiln's energy source with your facility's economic and process-specific goals.

Summary Table:

| Fuel Type | Key Characteristics | Common Applications |

|---|---|---|

| Natural Gas & Propane | Clean combustion, reliable temperature control | Industrial processes requiring consistent heat |

| Fuel Oil | Cost-effective, dependable in remote areas | Regions with limited gas infrastructure |

| Electricity | Precise temperature control, zero on-site emissions | High-purity material processing |

| Alternative Fuels (e.g., waste heat, syngas) | Enhances sustainability, uses waste streams | Energy-efficient and eco-friendly operations |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Our indirect-fired rotary kilns are designed to handle diverse fuels like natural gas, electricity, and waste heat, ensuring superior product purity and operational flexibility. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all customizable to meet your unique experimental needs. Don't let fuel limitations hold you back—contact us today to discuss how our tailored solutions can enhance your efficiency and reduce costs!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating