In Plasma-Enhanced Chemical Vapor Deposition (PECVD), a range of frequencies are used, but they are primarily categorized into two regimes. Low-frequency (LF) discharges typically operate in the range of 50-400 kHz, while high-frequency (HF) discharges almost universally use the industry-standard 13.56 MHz. The choice between them is a deliberate engineering decision that fundamentally alters the plasma characteristics and the properties of the resulting thin film.

The core principle is a trade-off: low frequency provides high-energy ion bombardment ideal for tuning film stress and density, while high frequency creates a high-density plasma that boosts deposition rates and minimizes substrate damage.

The Physics of Frequency in Capacitive Discharges

The frequency of the applied electric field determines how different particles in the plasma—namely the heavy, positive ions and the light, negative electrons—are able to respond. This response dictates the energy distribution within the reactor.

Low-Frequency (LF) Excitation: ~50-400 kHz

At low frequencies, the alternating electric field changes slowly enough for both the light electrons and the much heavier ions to accelerate and cross the plasma sheath during each cycle.

This results in high-energy ion bombardment on the substrate surface. Because the ions have time to be fully accelerated by the field, they strike the surface with significant kinetic energy.

LF excitation generally requires higher voltages to sustain the plasma compared to HF systems. This is because the plasma is effectively extinguished and re-ignited during each cycle, a state known as a "time-varying" plasma.

High-Frequency (HF) Excitation: 13.56 MHz

At the standard high frequency of 13.56 MHz, the electric field oscillates too rapidly for the heavy ions to respond. They are effectively immobile in the oscillating field, only responding to the average (DC) potential.

Only the lightweight electrons can keep up with the rapid field changes. This leads to a very efficient transfer of power to the electrons, causing them to oscillate and create more ion-electron pairs through collisions.

The result is a higher plasma density—more reactive species available for deposition—and a "time-independent" discharge. This allows for higher deposition rates at lower operating voltages, reducing the risk of damaging sensitive substrates.

Understanding the Trade-offs

Choosing a frequency is not about finding one "best" option, but about balancing competing process goals. The decision has direct consequences for film properties, deposition rate, and potential substrate damage.

Ion Energy vs. Plasma Density

This is the central trade-off. LF power is your primary lever for controlling ion energy. This is crucial for applications requiring dense films or specific mechanical properties, like compressive stress.

HF power is your primary lever for controlling plasma density. This is the key to increasing the generation of reactive chemical precursors, which directly translates to a higher deposition rate.

The Rise of Dual-Frequency Systems

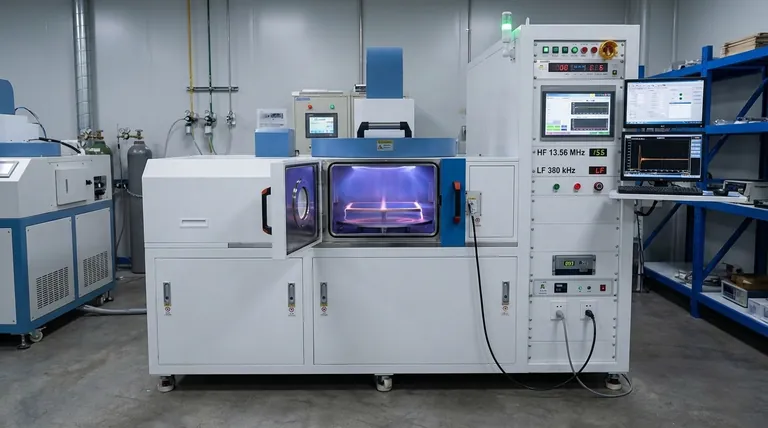

To overcome this fundamental trade-off, modern advanced PECVD systems often use a dual-frequency approach.

They combine a standard 13.56 MHz (HF) source to generate a high-density plasma with a separate LF source applied to the same electrode. This provides independent control: the HF power dictates the deposition rate, while the LF power separately tunes the ion bombardment energy to control film properties like stress, hardness, and density.

The Limits of Capacitive Coupling

While effective, capacitively coupled plasmas (both LF and HF) have an upper limit on the plasma density they can achieve.

For applications requiring extremely high deposition rates or unique film properties, other plasma sources like Inductively Coupled Plasma (ICP) or Electron Cyclotron Resonance (ECR) are used. These methods can generate plasma densities an order of magnitude higher than capacitive techniques.

Making the Right Choice for Your Goal

Your process requirements will determine the ideal frequency strategy for your PECVD application.

- If your primary focus is high deposition rate and minimizing substrate damage: A standard high-frequency (13.56 MHz) source is the most effective and common choice.

- If your primary focus is controlling film stress or achieving high density: A low-frequency source is necessary, but a dual-frequency system provides superior control by separating plasma generation from ion bombardment.

- If your primary focus is maximizing plasma density beyond what capacitive systems offer: You must look beyond capacitive coupling and consider alternative high-density sources like ICP.

Ultimately, understanding the role of frequency gives you a powerful lever to control the plasma environment and engineer thin films with precision.

Summary Table:

| Frequency Type | Range | Key Characteristics |

|---|---|---|

| Low-Frequency (LF) | 50-400 kHz | High-energy ion bombardment, ideal for tuning film stress and density |

| High-Frequency (HF) | 13.56 MHz | High plasma density, boosts deposition rates, minimizes substrate damage |

Unlock Precision in Your Lab with KINTEK's Advanced PECVD Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs—whether you require high deposition rates, controlled film stress, or enhanced plasma density.

Contact us today to discuss how our PECVD systems can optimize your thin film processes and drive your research forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition